Harmless treatment method for household garbage

A technology for harmless treatment and domestic waste, applied in chemical instruments and methods, grain treatment, solid waste removal, etc., can solve the problems of single, low carbonization efficiency, etc., to reduce labor intensity, high degree of automation, improve crushing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

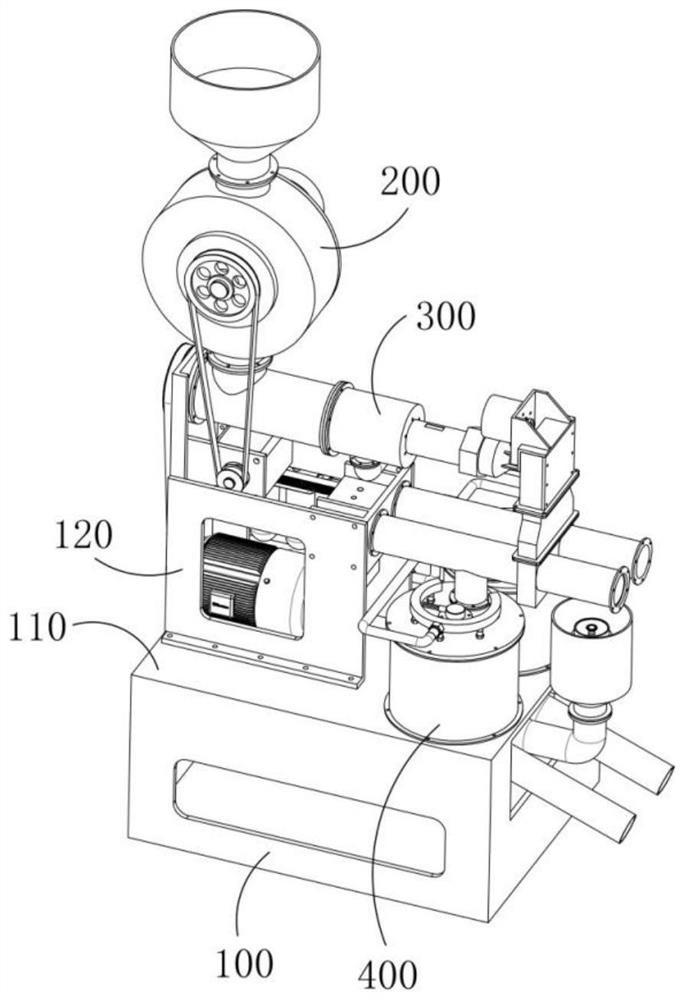

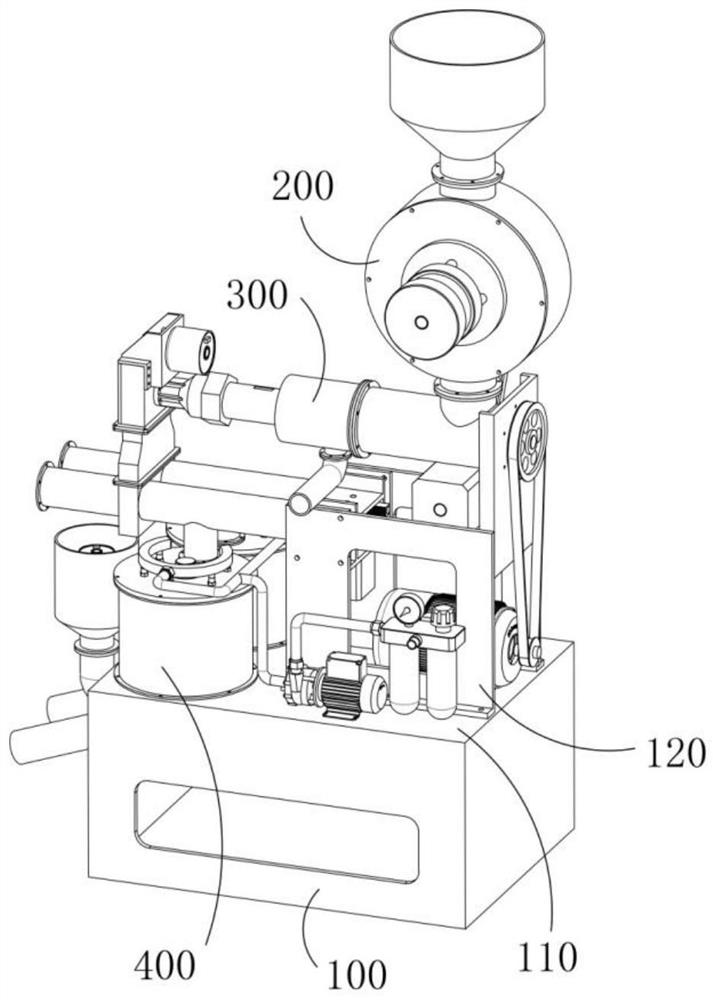

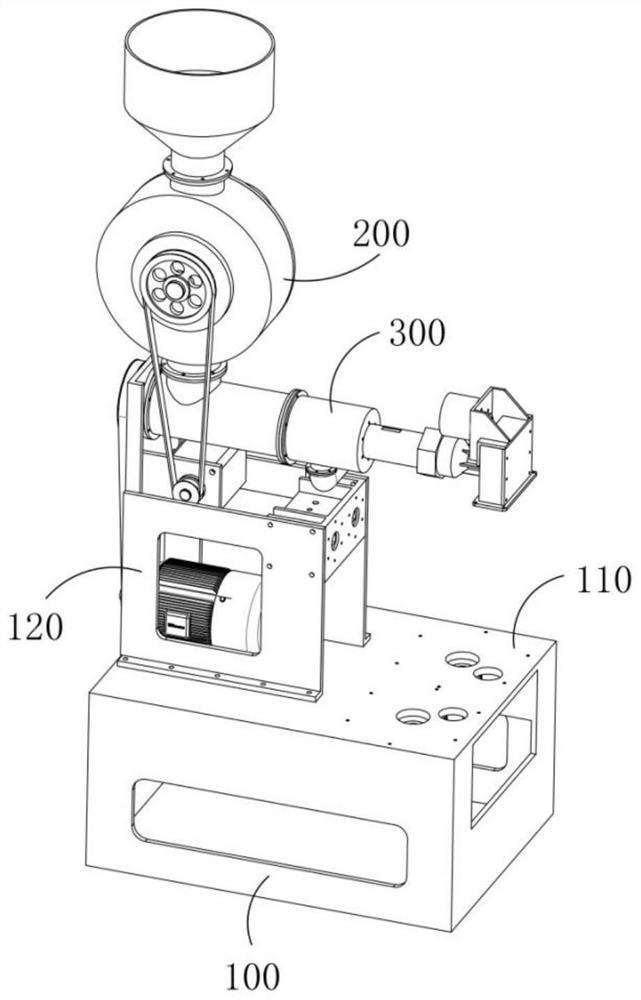

[0060] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0061] The harmless treatment method of domestic garbage, its steps are:

[0062] S1: Dump domestic waste into the crushing and feeding device 200, and the crushing and feeding device 200 crushes the domestic waste and then transports it to the water removal and compression device 300;

[0063] S2: the water removal and compression device 300 installed on the installation bracket 100 receives the crushed household garbage;

[0064] The mounting bracket 100 is installed on the ground, the top of the mounting bracket 100 is horizontally fixed with a mounting plate 110, and the upper end surface of the mounting plate 110 is fixed with a fixed bracket 120;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com