Anti-radiation shielded conveying passageway used for electron beam curing of plane panel coating

An electron beam curing, flat plate technology, used in conveyors, rollers, transportation and packaging, etc., can solve problems such as low operation efficiency, radiation leakage, human injury, etc., to avoid injury, reduce radiation, and maintain uniform thickness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

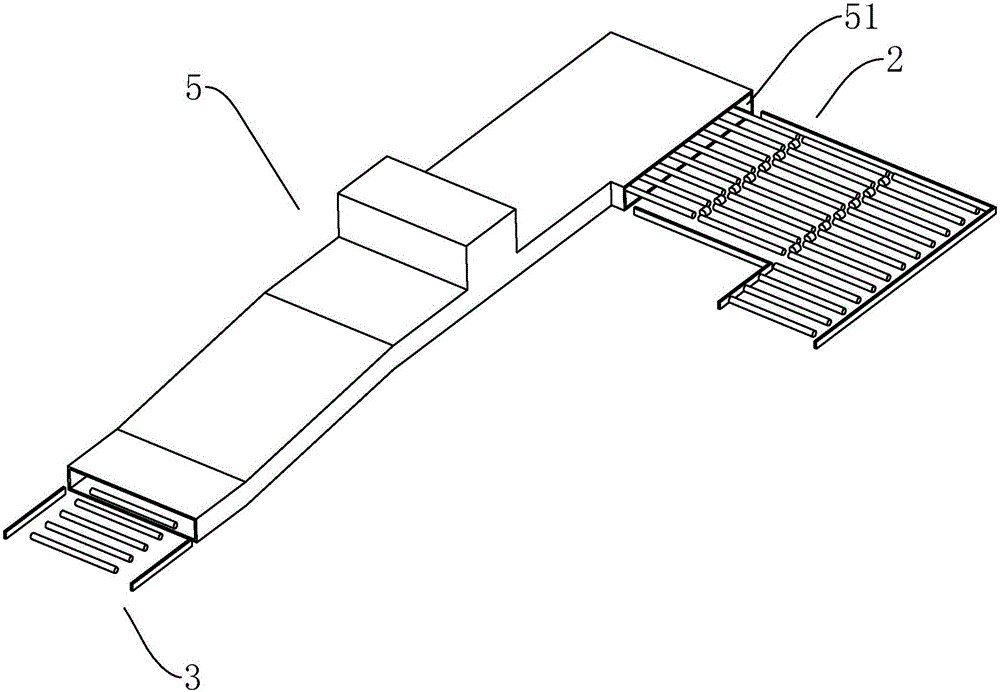

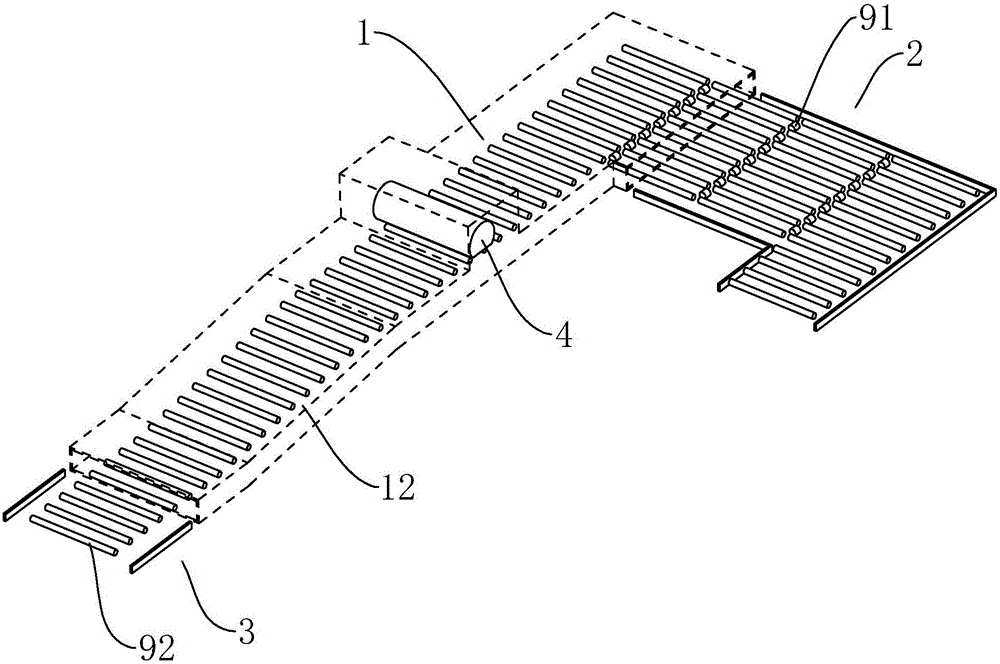

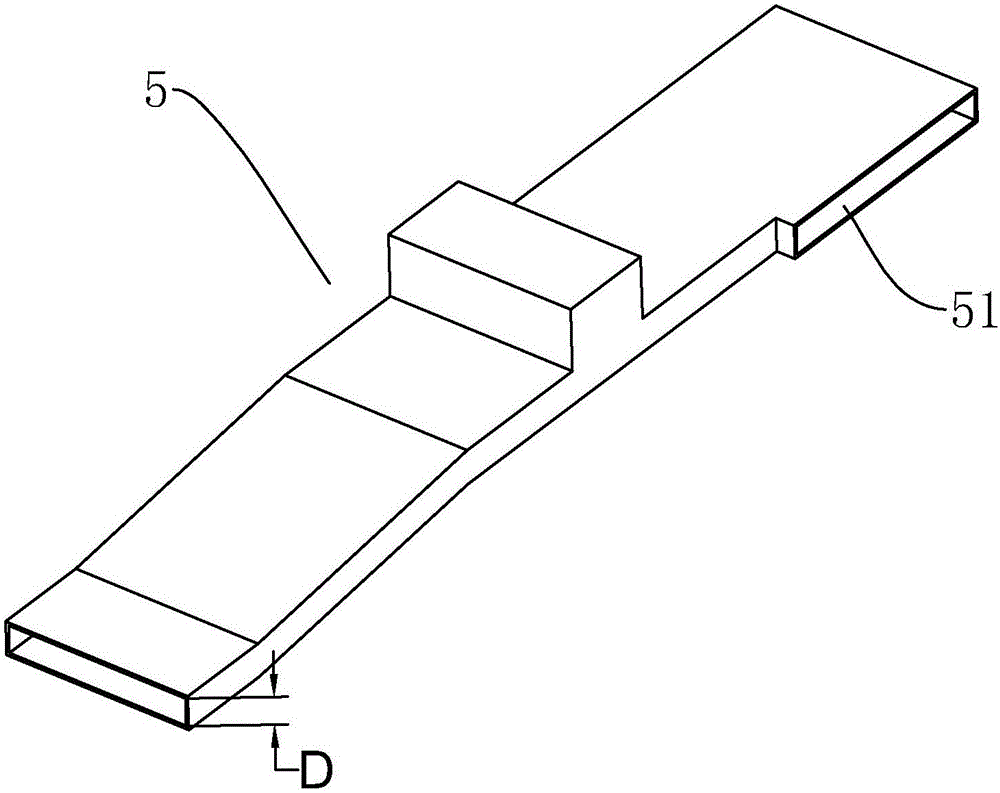

[0020] refer to Figure 1 to Figure 3 , Figure 1 to Figure 3 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, a radiation-proof shielding conveying channel for flat plate coating electron beam curing includes a radiation channel 1, a feed channel 2 and a discharge channel 3. The radiation channel 1 is provided with an electron beam emitting device 4, the radiation channel 1 is provided with a shielding shell 5 covering the radiation channel 1 and the electron beam emitting device 4, and the side of the shielding shell 5 at the feed end of the radiation channel 1 A feed port 51 is provided, the feed channel 2 is connected to the radiation channel 1 from the feed port 51, the discharge channel 3 is lower than the radiation channel 1, and the discharge end of the radiation channel 1 is passed through an oblique outlet The material connection channel 12 is connected to the discharge channel 3 , and the end of the shi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com