Vertical template system

A vertical formwork and system technology, applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, and preparation of building components on site, can solve the impact of construction efficiency, complicated steps, wear and tear, etc. Inconvenient fixed connection between wall rods and vertical formwork, etc., to achieve the effect of improving construction efficiency, convenient installation and disassembly, and reducing installation and fixing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be described in detail below in conjunction with the embodiments of the present invention, but the following embodiments are only used to understand the present invention, and cannot limit the present invention. The present invention can be implemented in a variety of different ways defined and covered by the claims .

[0031]

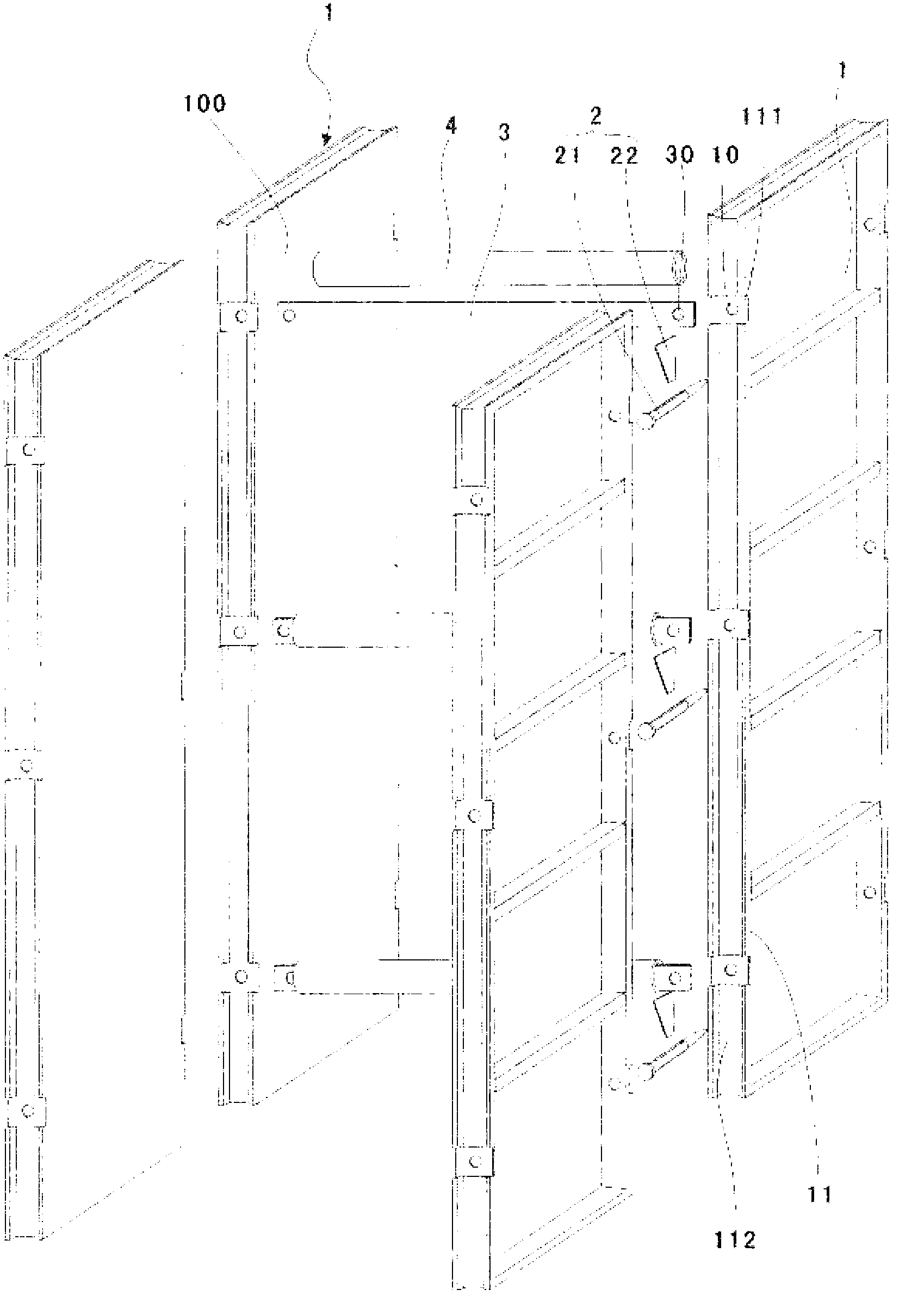

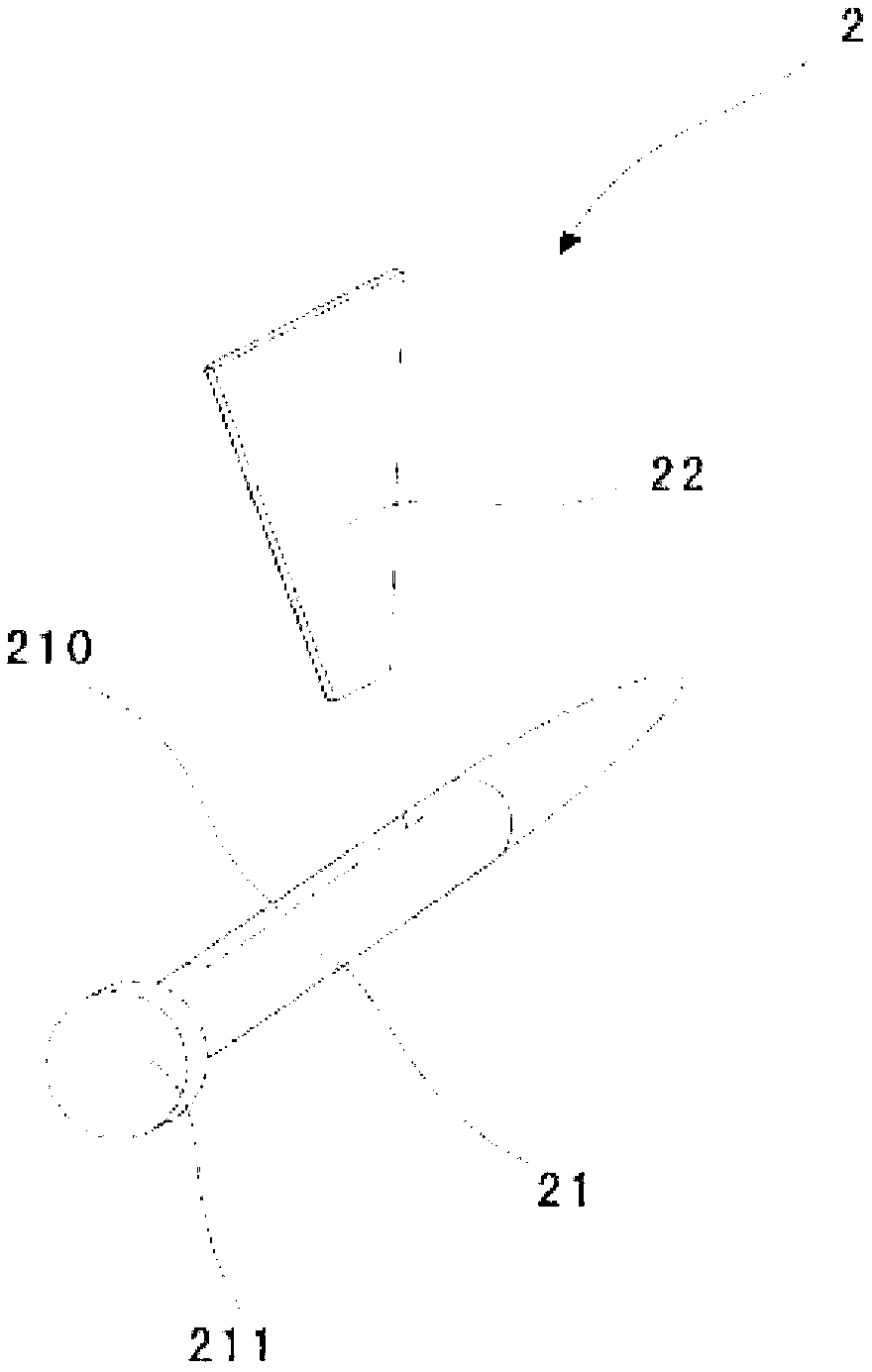

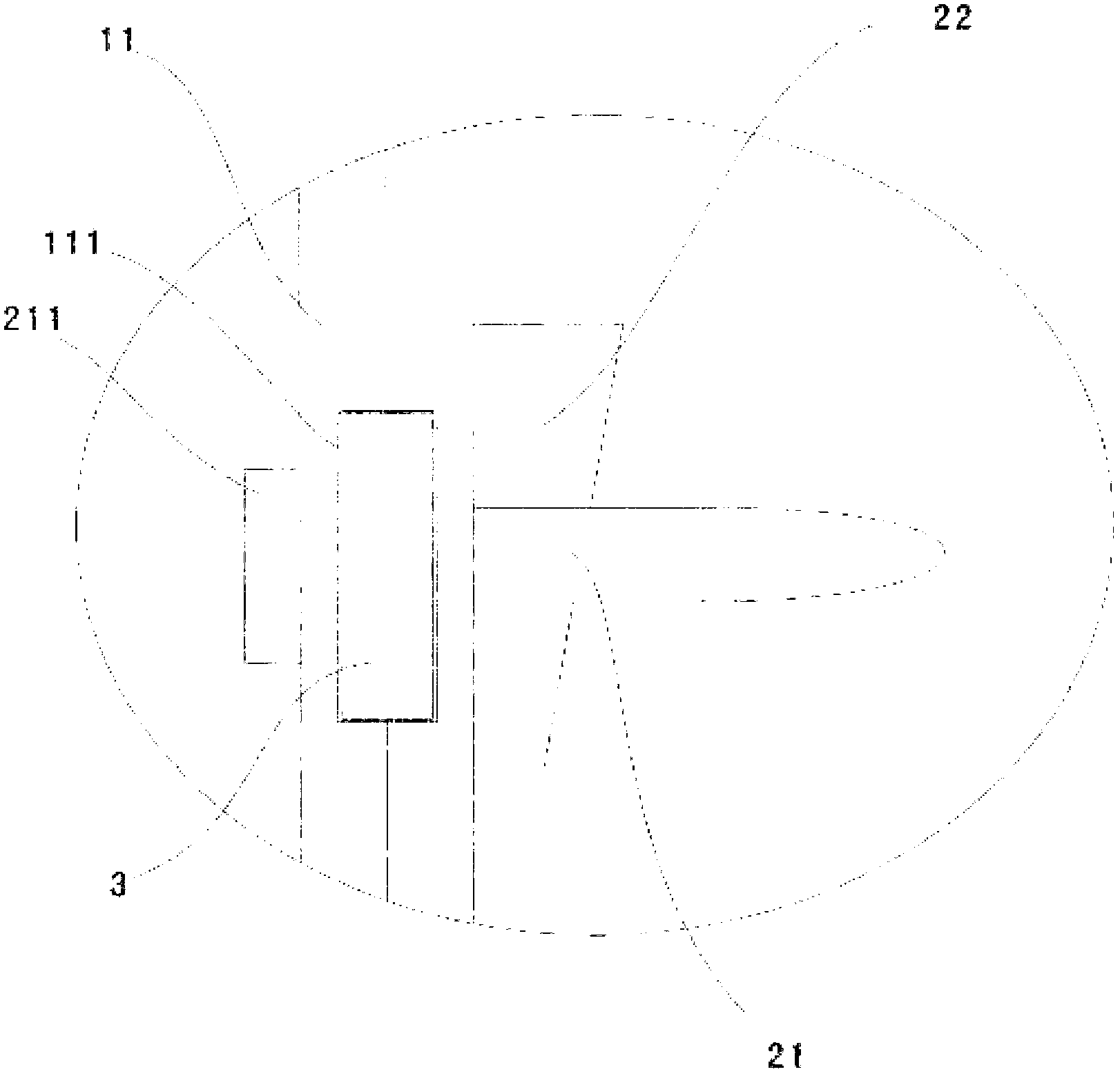

[0032] see figure 1 -3, shows an embodiment of a vertical formwork system of the present invention, including a plurality of vertical formworks 1 , fastening devices 2 and strip-shaped braces 3 . A plurality of vertical templates 1 are arranged and fixed on both sides of the precast wall. The brace 3 runs through the precast wall, and its two ends in the length direction are respectively fixedly connected to the vertical formwork 1 on both sides of the precast wall, and between two adjacent vertical formwork 1 on the same side of the precast wall It is fixedly connected by the firm device 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com