Power transmission device

A power transmission device and input shaft technology, applied in the direction of power devices, electric power devices, transmission parts, etc., can solve problems such as cavitation failure, oil pump pressure head drop, failure, etc., achieve simple structure and prevent cavitation failure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

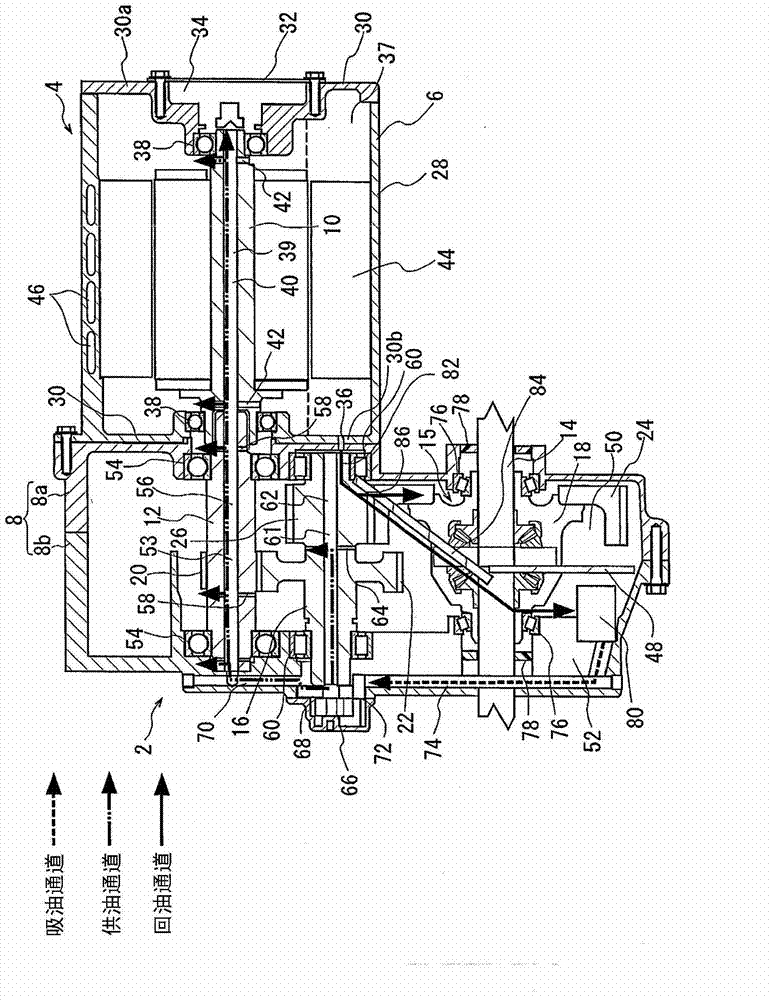

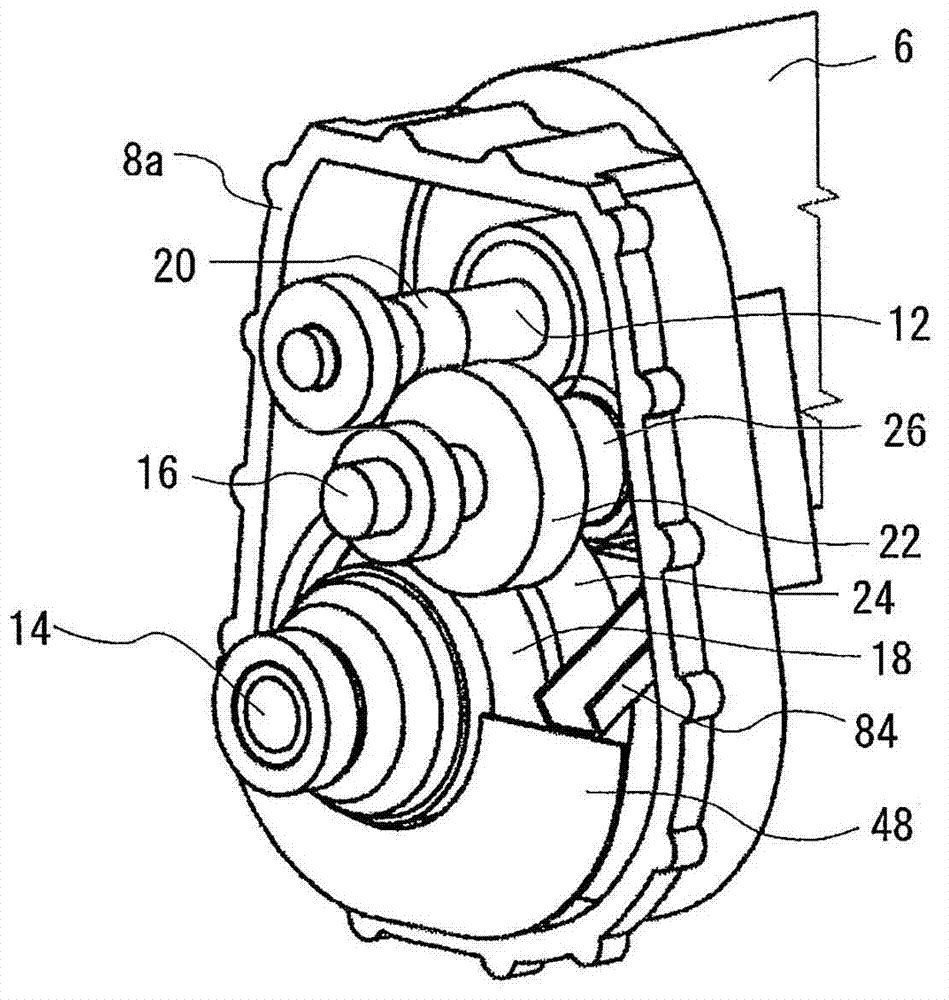

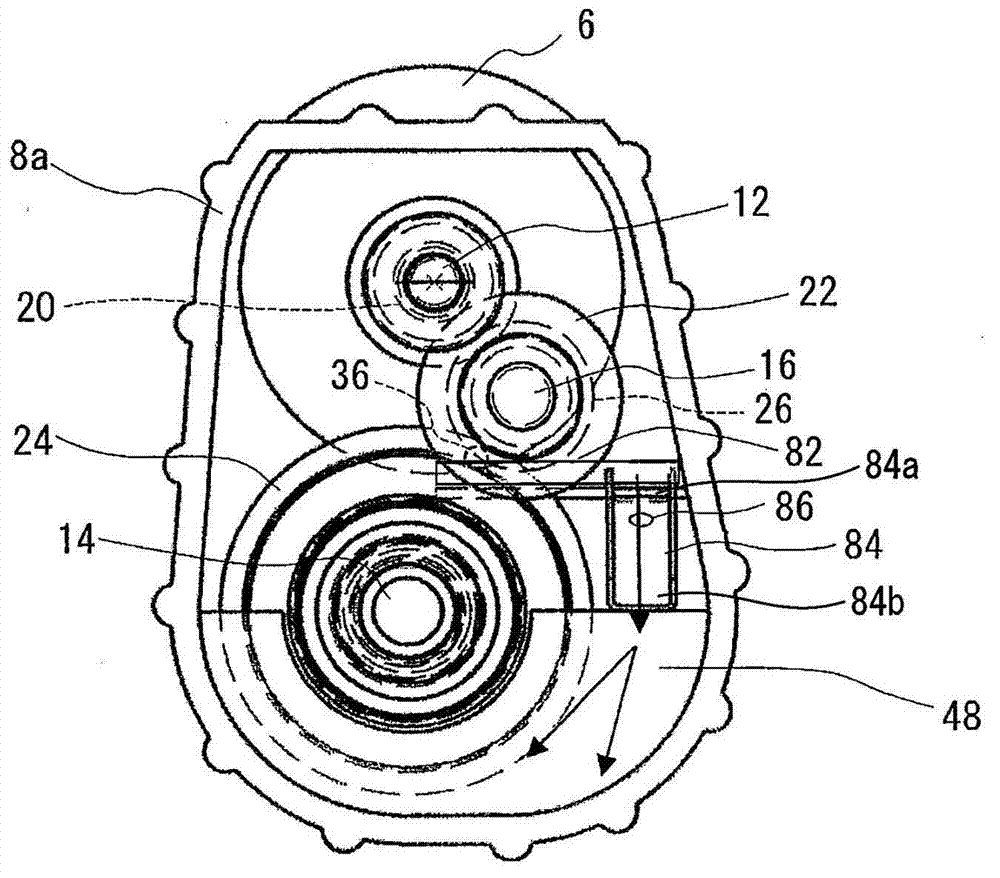

[0024] The following will refer to Figure 1 to Figure 3 An embodiment of the power transmission device 2 is explained. figure 1 Shown are the electric motor 4 and the power transmission device 2 that transmits the driving force generated by the electric motor 4 to the left and right wheels of the vehicle.

[0025] The power transmission device 2 mainly includes: an input shaft 12 connected to figure 1 The rotor shaft 10 of the electric motor (vehicle drive motor) 4 at the left end shown in ; the output shaft 14 , which is arranged parallel to the input shaft 12 ; One end of the motor casing (housing) 6 (in the figure 1 , corresponding to the connection part between the input shaft 12 and the output shaft 14 in the gear housing (housing) 8 at the left end). The motor case 6 and the gear case 8 serve as a case.

[0026] A differential gear 15 is formed on the periphery of the output shaft 14 . The differential gear 15 is housed in a gear case 18 pivotally supported on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com