Combination optical lens light-emitting diode (LED) motorcycle headlamp

An optical lens and motorcycle technology, which is applied to light sources, electric light sources, motor vehicles, etc., can solve the problems of large volume, complicated heat dissipation measures of light intensity, high cost, and complicated structure of headlights, etc., and achieves low cost, simple structure, Simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

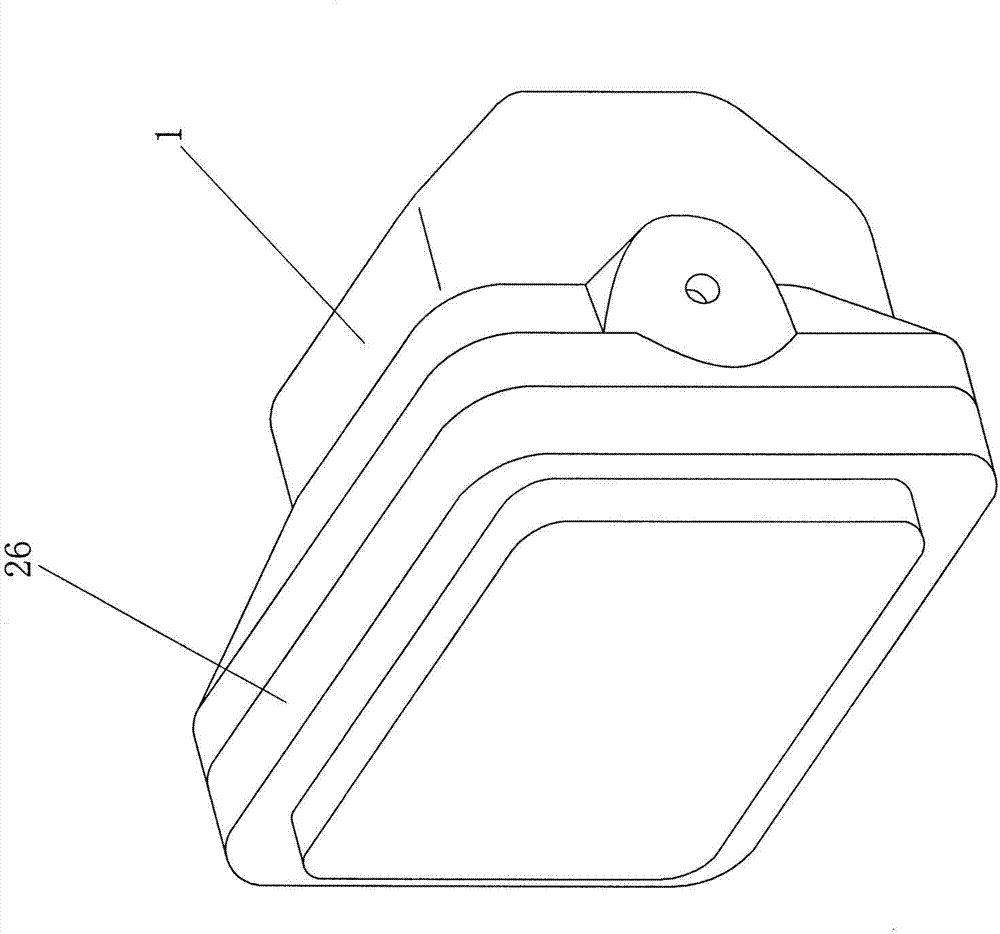

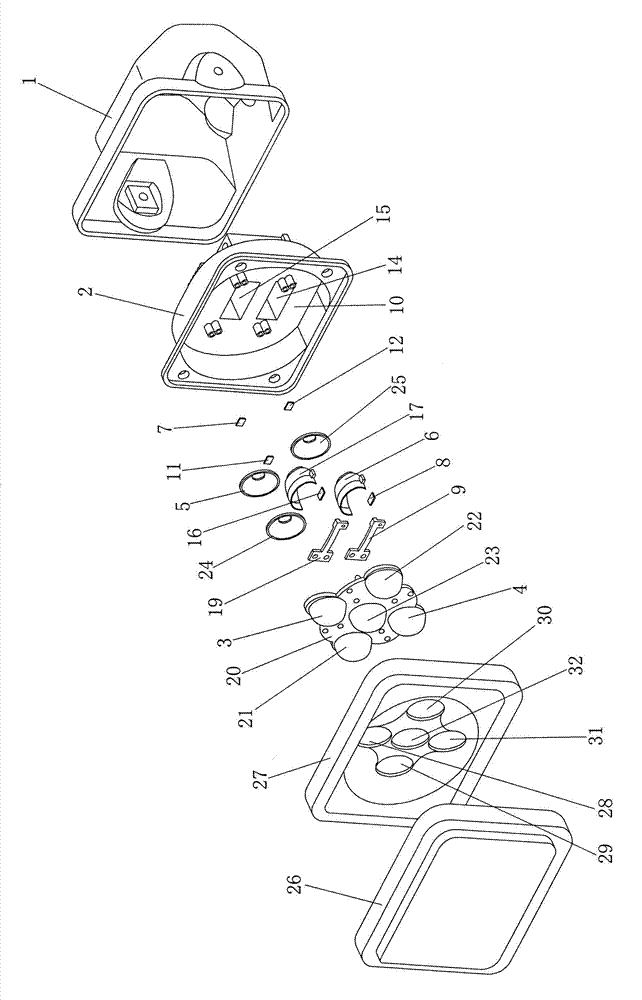

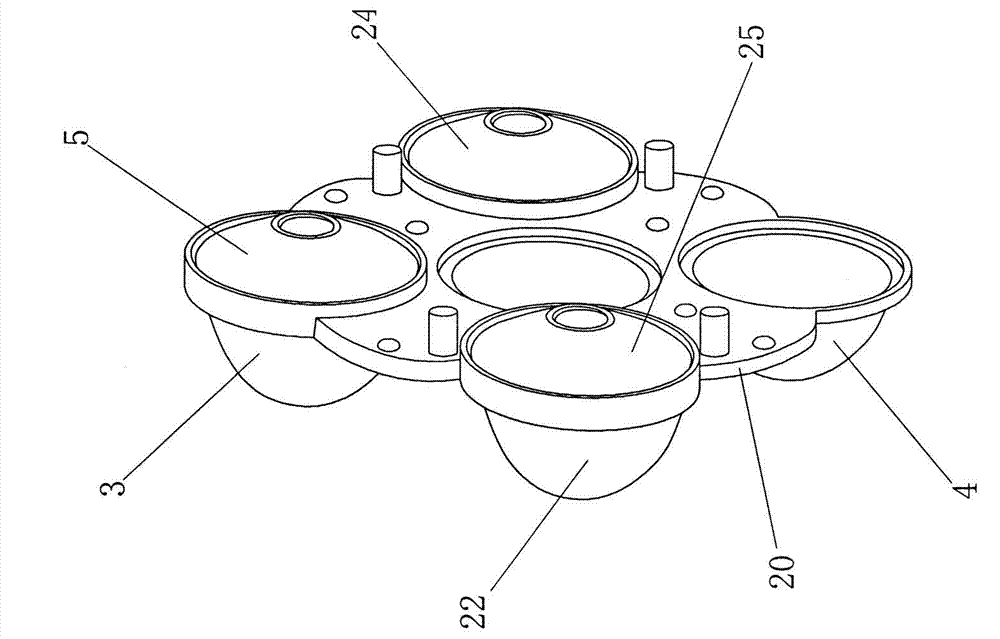

[0024] refer to Figure 1 ~ Figure 4 , the combined optical lens LED motorcycle headlights, including lamp housing 1, radiator 2, high beam optical convex lens 3, low beam optical convex lens 4, high beam reflector 5, low beam reflector 6, The high-beam LED light source 7, the low-beam LED light source 8, and the light barrier 9 are characterized in that: the radiator 2 is installed and fixed on the lamp housing 1, and there is a vertical installation plane 10 on it, and there are three high-beam LED light sources 7, 11 and 12 are respectively mounted on the upper side, the left side, and the right side of the center of the installation plane 10, and the light-emitting surfaces 13 of the high-beam LED light sources 7, 11 and 12 are facing forward, at the center of the center of the installation plane 10 and There are two low-beam chambers 14 and 15 extending inward on the lower side, and two low-beam LED light sources 8 and 16 are installed on the lower mounting surfaces of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com