Full-automatic multi-channel absorbance measuring instrument

An absorbance and multi-channel technology, applied in color/spectral characteristic measurement, instruments, analytical materials, etc., can solve the problems of staff health hazards, difficult precision, low measurement efficiency, etc., to achieve reduced hazards, high detection accuracy, and easy The effect of installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

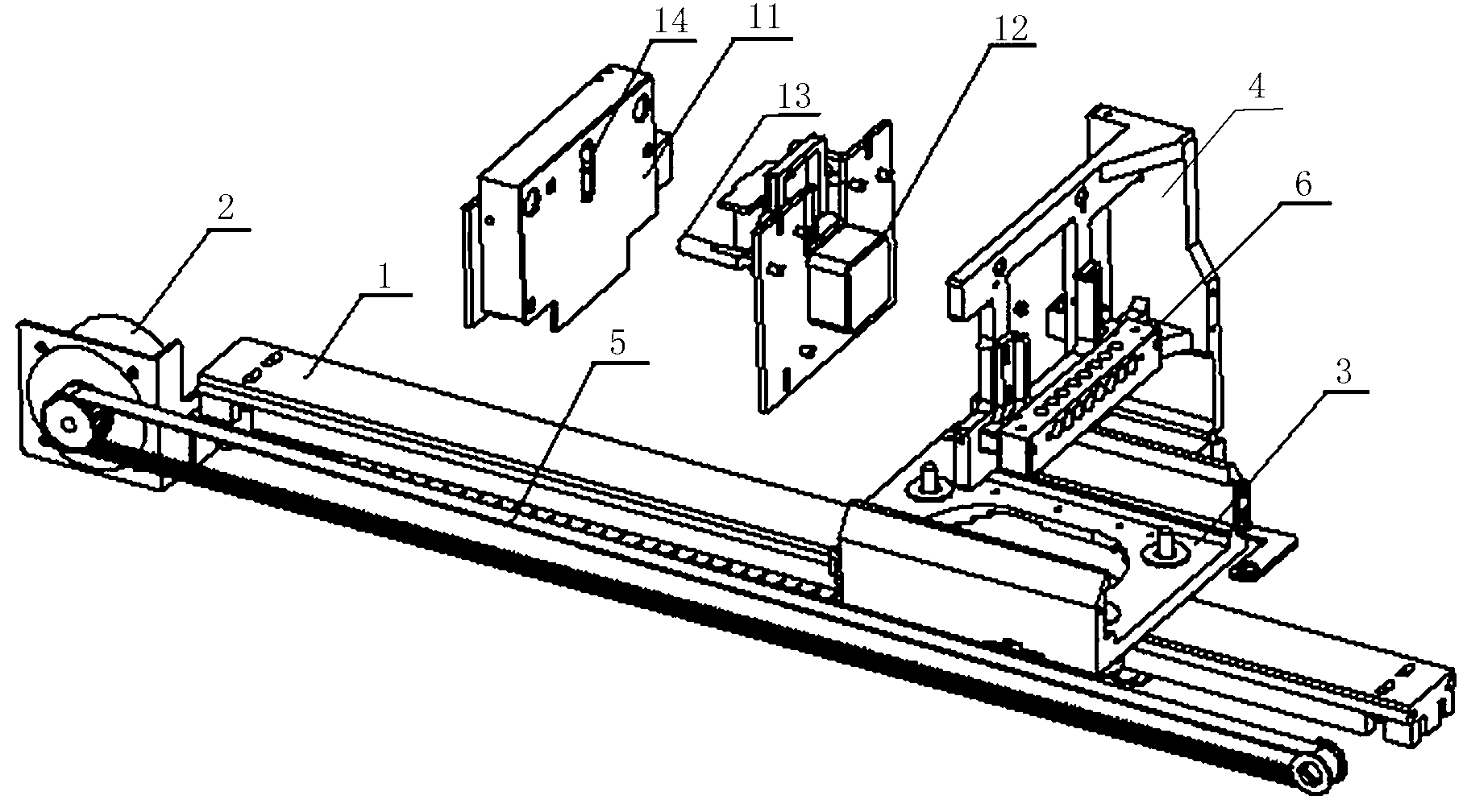

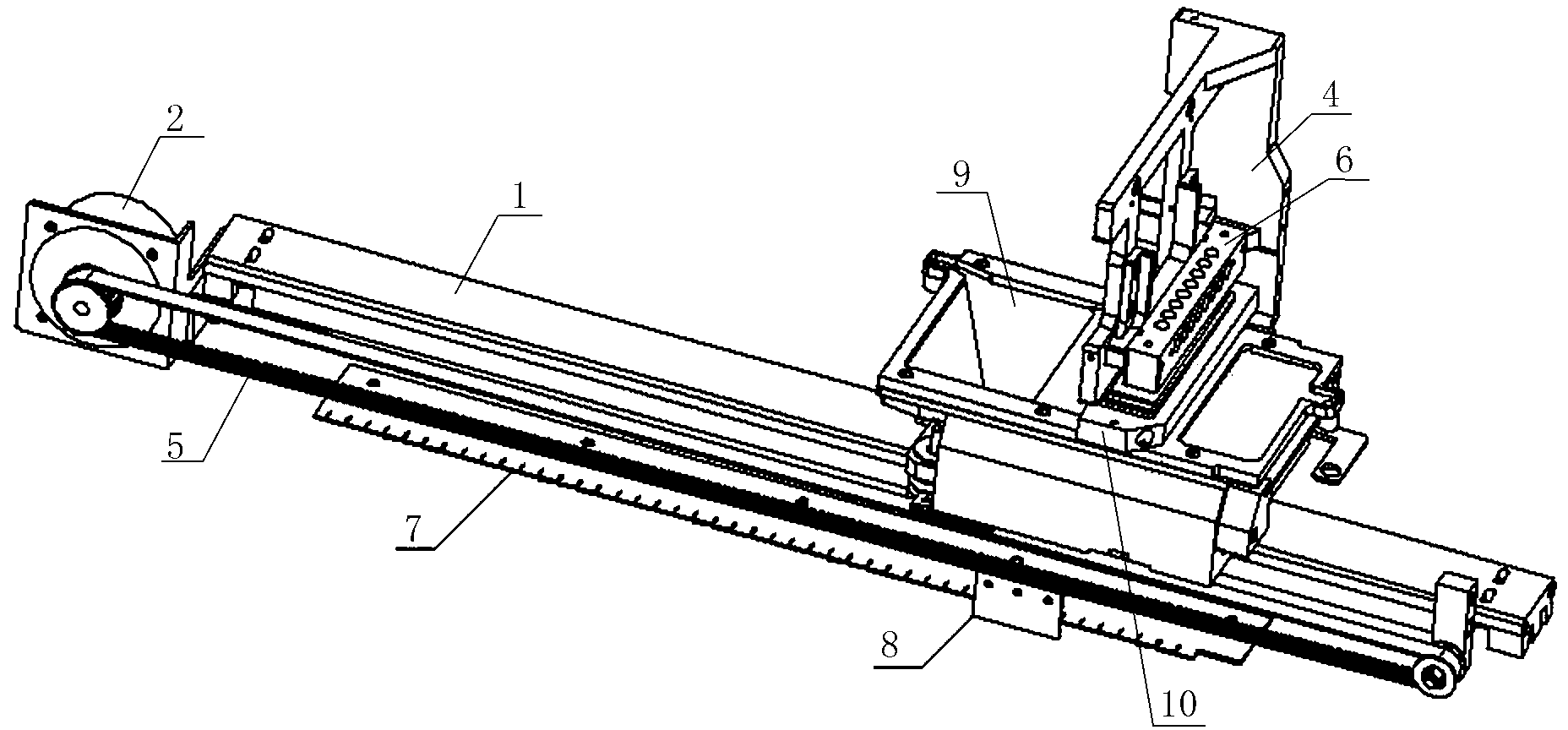

[0018] Such as figure 1 A schematic structural diagram of the fully automatic multi-channel absorbance measuring instrument of the present invention is given, which includes a cleaning device, a control circuit part, a mechanical track 1, a stepping motor 2, a reading box bracket 3, a support frame 4, a timing belt 6, and a lamp Block 6, an absorbance reading box 9 and a microplate 10 for the liquid to be tested. The mechanical track 1 shown should be set on the corresponding frame for guiding and positioning the reading box bracket 3; the stepper motor 2 is powered by the synchronous belt 5. The timing belt 5 is fixed to the reading box bracket 3, and the absorbance reading box 9 is arranged on the reading box bracket 3; the lamp block 6 is fixed on the supporting frame 4, and the supporting frame 4 is fixed to the reading box bracket 3. In this way,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com