Multi-channel micro-volume sampling device

A sample adding device and micro-volume technology, applied in analytical materials, instruments, etc., can solve the problems of inability to meet actual requirements and low efficiency, improve sampling and sample adding efficiency, ensure the accuracy of results, and avoid cross-contamination effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with the accompanying drawings.

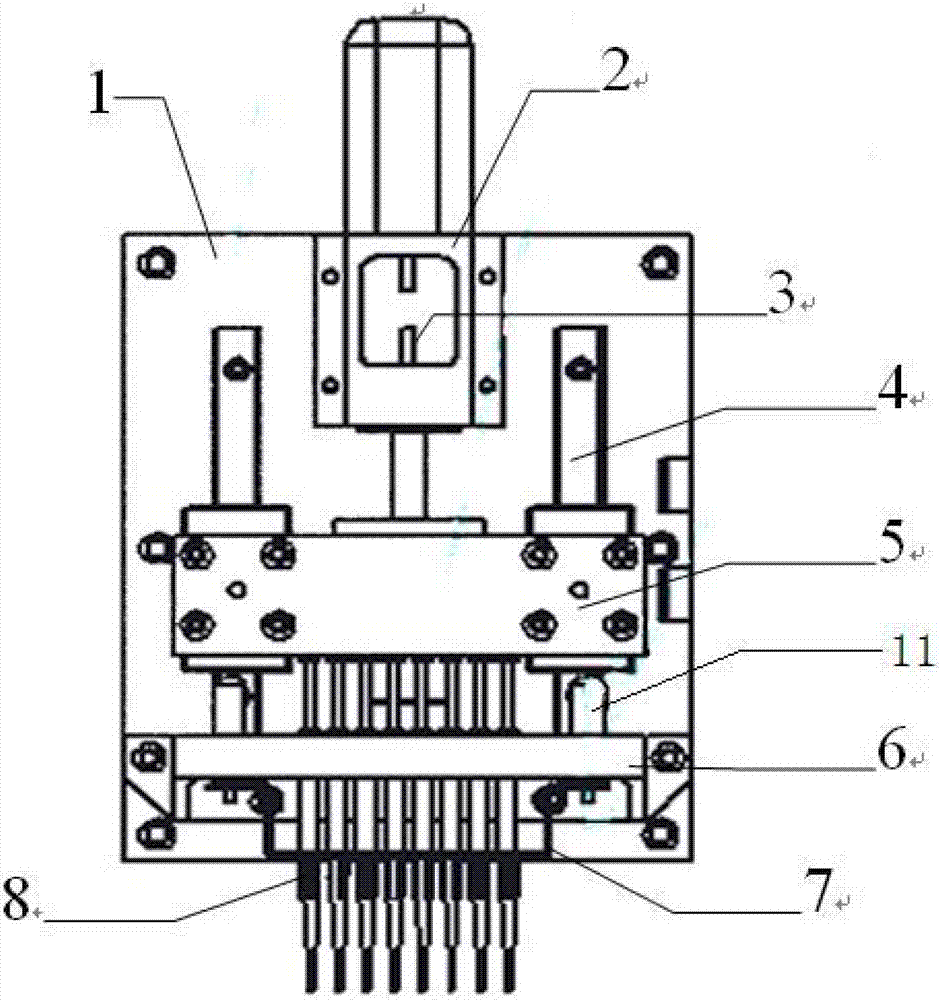

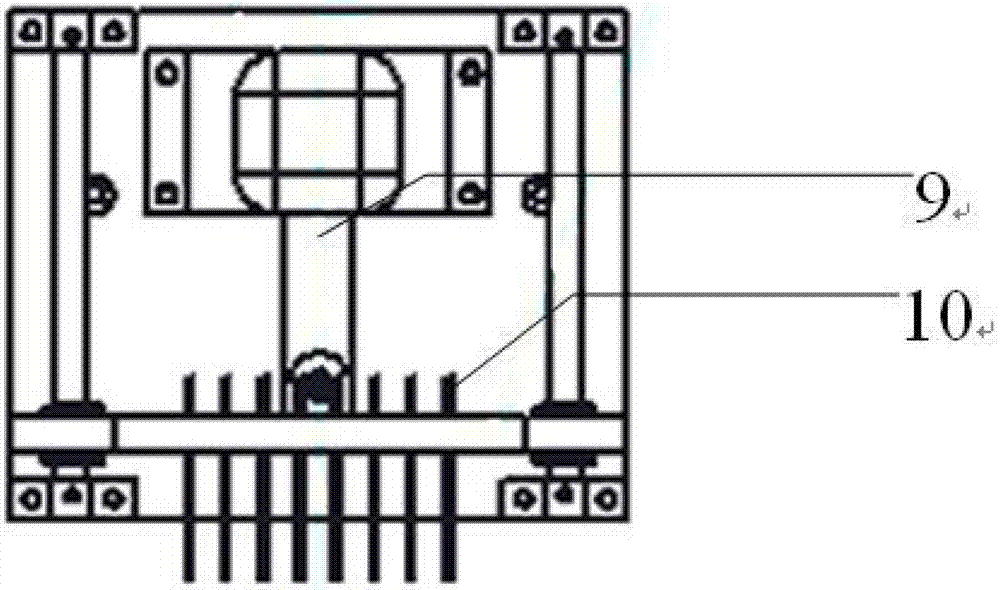

[0017] like figure 1 , 2 As shown, the present invention includes a base plate 1 on which a drive system is installed. The drive system includes a motor bracket installed on the base plate 1, and a motor 2 is installed on the motor bracket. The output shaft of the motor 2 is connected with the ball screw 3 through the coupling 3, the ball screw 3 is provided with a nut, the nut is fixed on the needle center mounting plate 5, and the center line of the ball screw 9 coincides with the base plate 1. The two ends of the needle center mounting plate 5 are respectively fixed on two sliders by nuts, and the two sliders are respectively installed on the linear guide rails 4 adapted thereto, and several needle cores 10 are fixed on the needle core mounting plate 5 . A needle tube mounting plate 6 is arranged below the needle core mounting plate 5, and the needle tube mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com