Optical cable for remote radio head and manufacturing method of optical cable

A technology of wireless radio frequency and optical cable, which is applied in the direction of fiber mechanical structure, etc., can solve the problems that the bending radius cannot meet the requirements of use, the original performance of optical fiber is difficult to restore, and the investment in stranding equipment is expensive. The effect of low battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

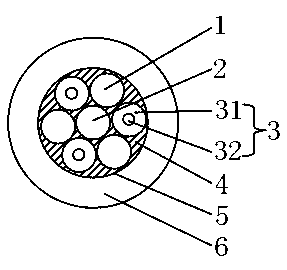

[0038] please see figure 1 , a wireless radio frequency remote optical cable, which includes a central strength member 2, a plurality of filling ropes 1, a plurality of tight sleeve optical fibers 3, surrounding strength members 4, a wrapping layer 5, and a sheath layer 6; it is characterized in that The filling rope and tight-sleeved optical fiber are distributed at intervals around the central strength member and are distributed parallel to the central strength member. The surrounding strength members are located in the cable core gap formed by the central strength member, filling rope, and tight-sleeved optical fiber. The wrapping layer is wrapped in the tight sleeve Outside the optical fiber, the sheath layer is extrusion-coated outside the wrapping layer; the tight-sleeved optical fiber is composed of a natural color or colored optical fiber 32 positioned at the inner layer, and a tight-sleeved layer 32 positioned at the outer layer; the sheath layer is composed of the ...

Embodiment 2

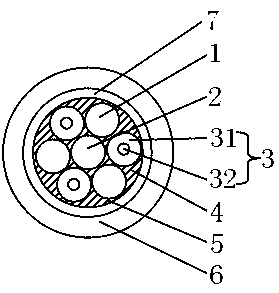

[0040] please see figure 2 , a wireless radio frequency remote optical cable, basically the same as the embodiment 1, the difference is that there is a coating layer 7 between the coating layer and the sheath layer; the coating layer is longitudinally coated or spirally coated on the coating layer External; the material of the cladding layer is water blocking tape or non-woven fabric or polyester tape.

Embodiment 3

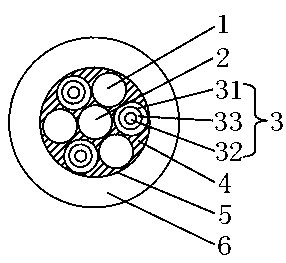

[0042] please see image 3 , a wireless radio frequency remote optical cable, basically the same as the implementation example 1, the difference is that the tight sleeve optical fiber is composed of a natural color or colored optical fiber 32 located in the inner layer, a transition layer 33 located in the middle, and a tight sleeve located outside the transition layer Cover layer 32 constitutes;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com