rotating electrical machine

A technology of rotating motors and rotating shafts, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., which can solve the problems of high corrosion and aging of casing parts, and reduced water resistance, and achieve excellent water resistance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

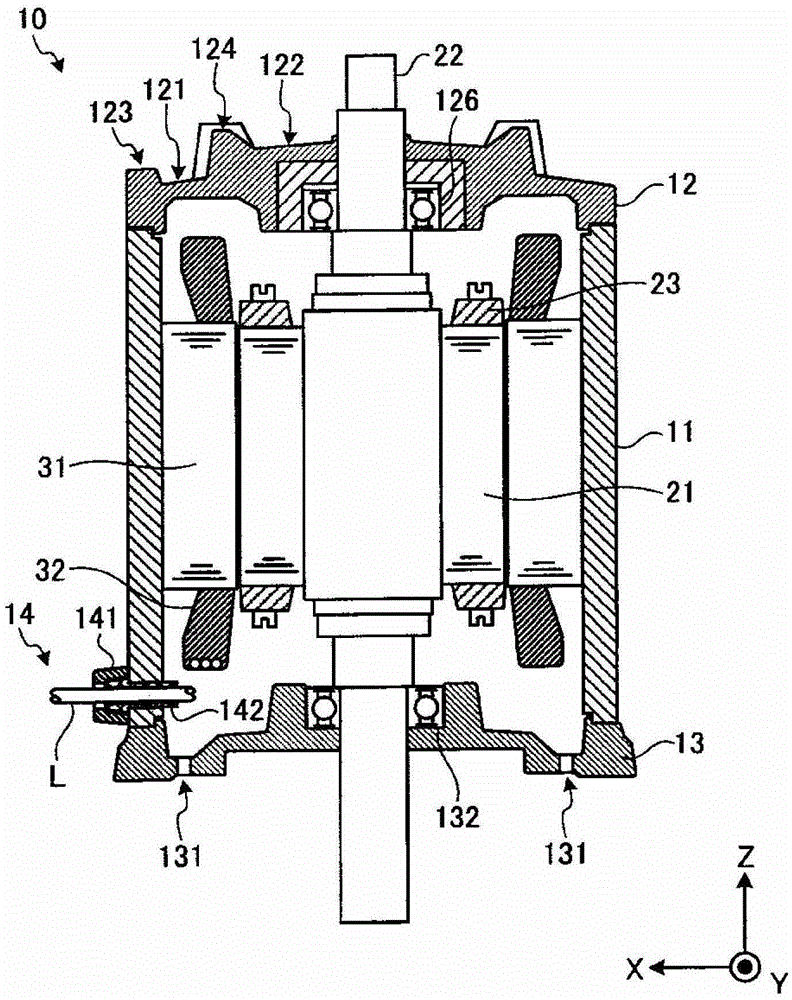

[0050] Hereinafter, embodiments of the rotating electric machine disclosed in the present application will be described in detail with reference to the drawings. In addition, this invention is not limited to embodiment shown below.

[0051] In addition, in the following, a rotating electric machine used as a spindle motor of a machine tool that performs cutting in an atmosphere containing a large amount of mist cutting fluid will be described as an example.

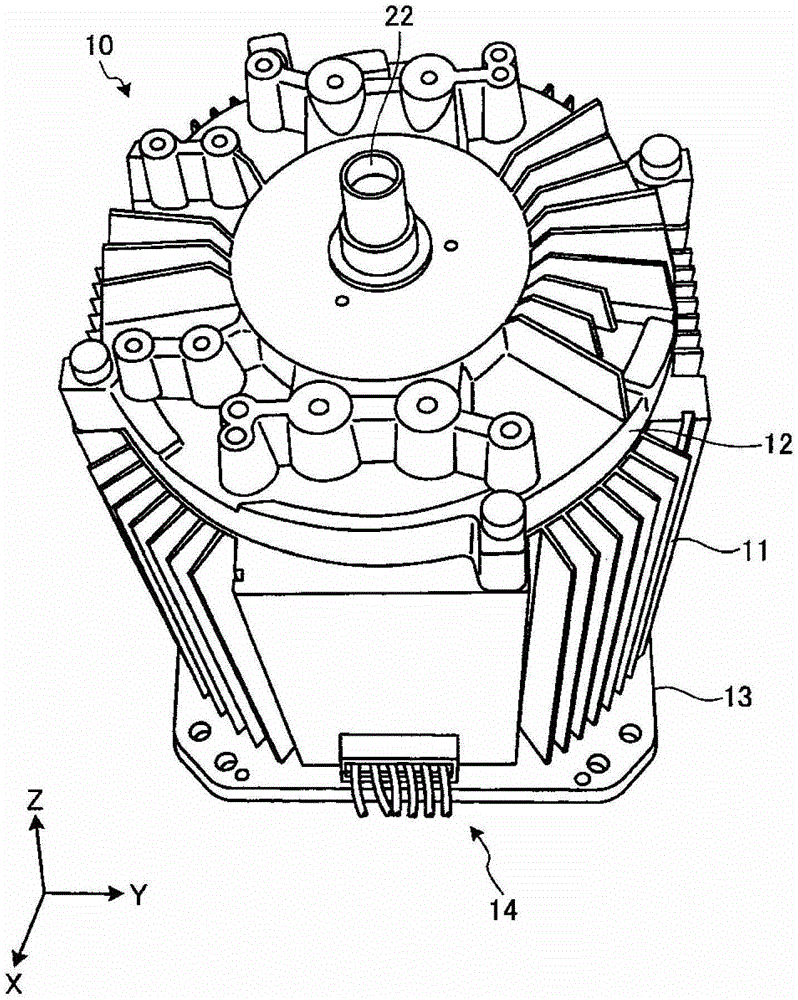

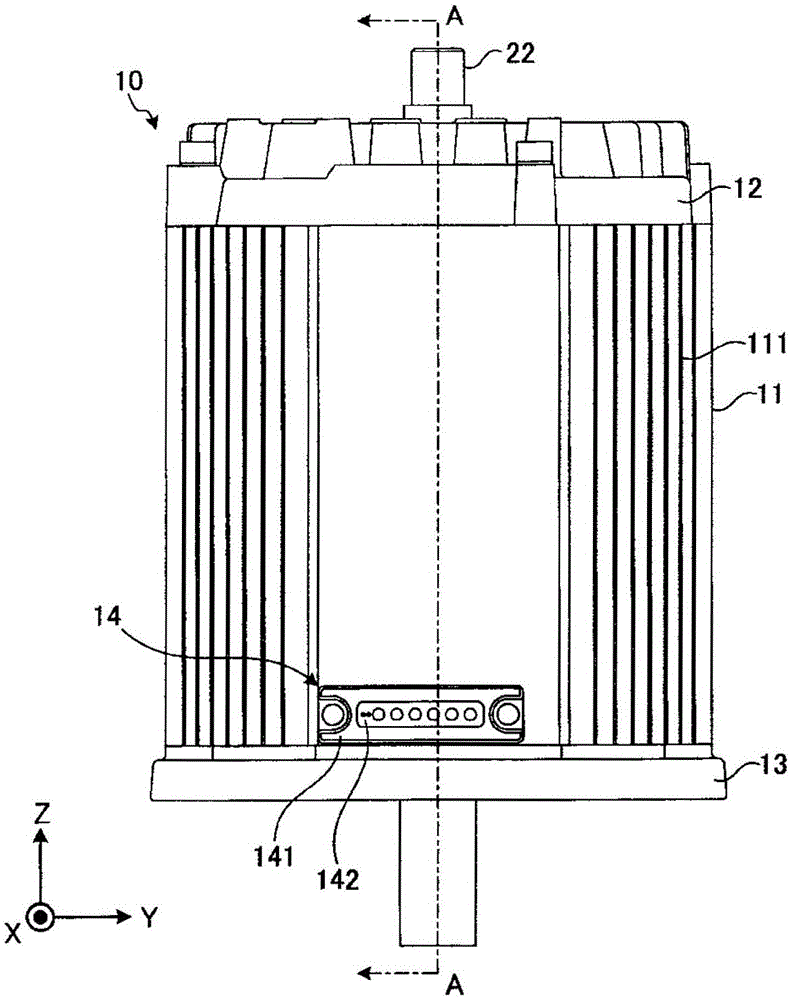

[0052] First, use figure 1 A schematic configuration of the rotating electric machine according to the embodiment will be described. figure 1 It is a perspective view of the rotating electrical machine 10 of embodiment.

[0053] And, for ease of understanding, the figure 1 , illustrates a three-dimensional Cartesian coordinate system including a Z-axis with a vertically upward direction as a positive direction and a vertically downward direction (ie, “vertical direction”) as a negative direction. In other drawings use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com