Control circuit for three-phase high power factor rectifier

A high power factor, control circuit technology, applied in the field of rectifiers, can solve the problems of complex control, poor control effect, and difficult to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

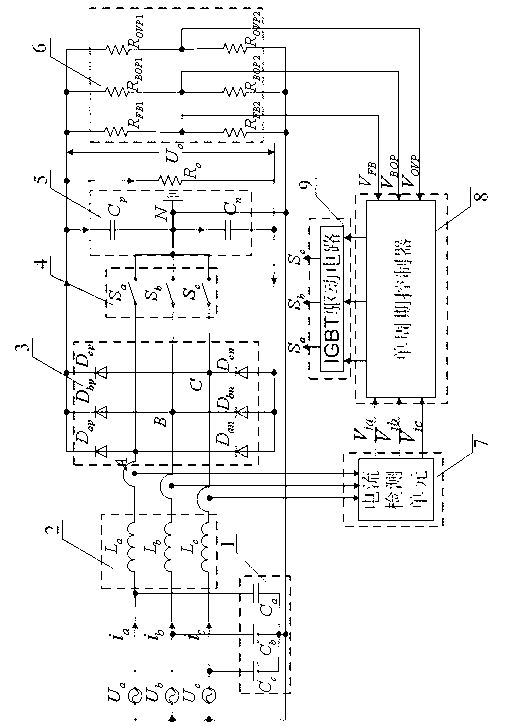

[0037] The control circuit of the three-phase high power factor rectifier of the present embodiment, such as figure 1 As shown, it includes input high-frequency filter circuit 1, three-phase input inductor 2, three-phase rectification circuit 3, switch tube power circuit 4, output rectification filter circuit 5, voltage division detection circuit 6, input current detection unit 7, single-cycle A controller 8 and a switch tube drive circuit 9.

[0038] The input high-frequency filter circuit 1 includes three ceramic capacitors C with a withstand voltage of 630V and a size of 2.2uF a 、C b and C c , C a 、C b and C c One end of the grid is respectively connected to the grid A-phase voltage input terminal, the grid B-phase voltage input terminal and the grid C-phase voltage input terminal, and the other end is connected to the neutral wire of the three-phase four-wire electricity at the same time, and the neutral wire is grounded. The three-phase input inductor 2 includes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com