Pneumatic seeder

An air-suction seeder technology, which is applied in the direction of sowing seeder, seeder parts, planting methods, etc., can solve the problems of low seeding efficiency, low operation efficiency of the whole machine, uneven distribution of pulsating seed grooves, etc. , to achieve the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

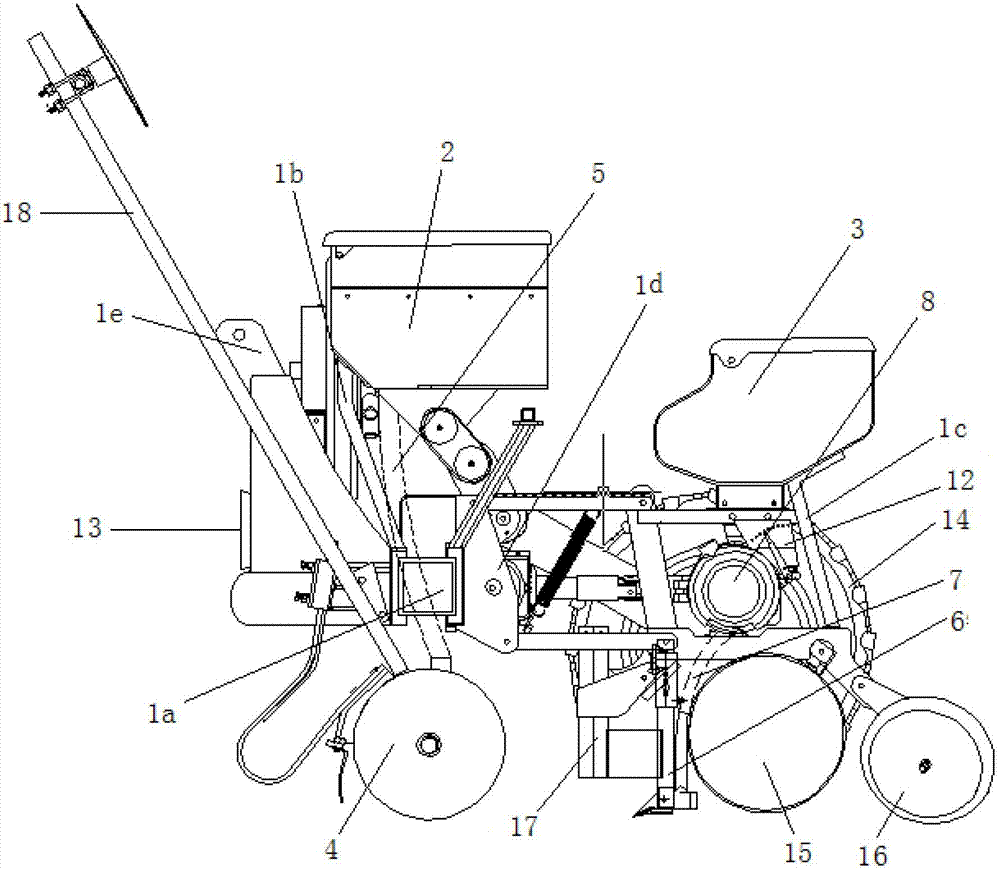

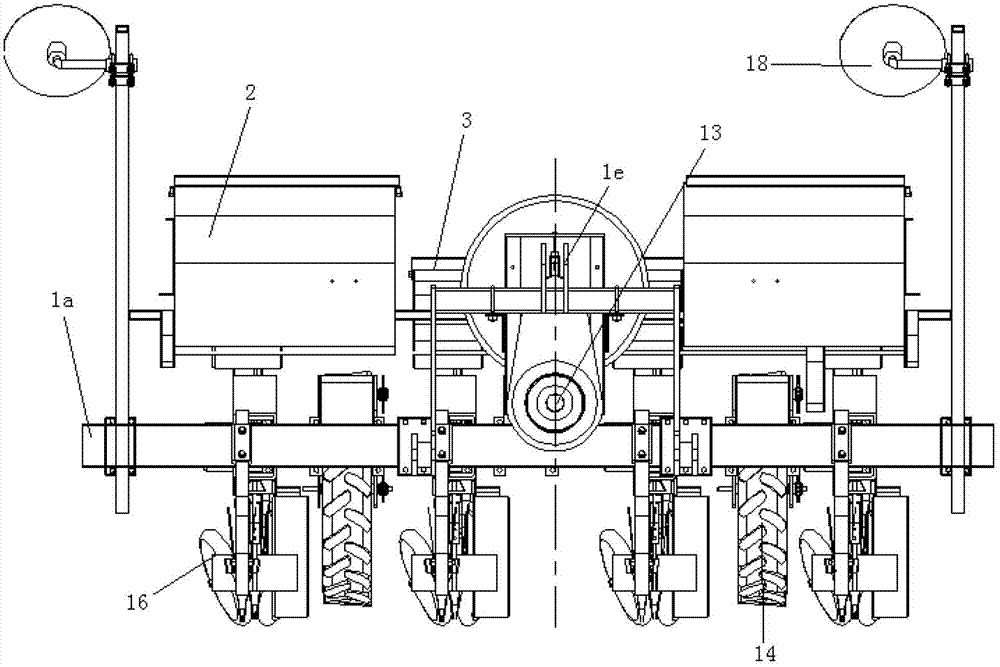

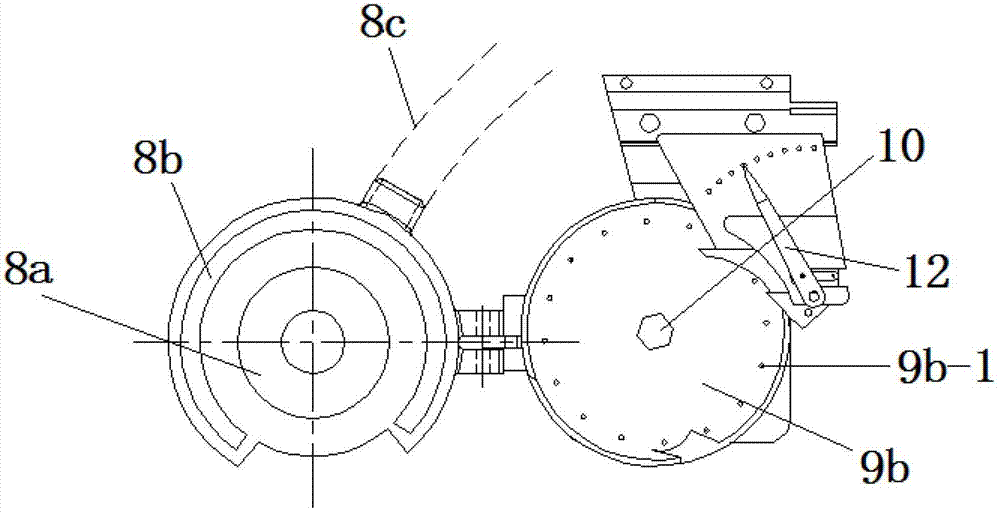

[0019] see figure 1 and figure 2 , a kind of air-suction seeder provided by the present invention comprises frame 1, and described frame 1 comprises beam 1a, fertilization support 1b, sowing support 1c, ditch opener support 1d and hanger 1e, and described fertilization support 1b It is fixed symmetrically above the crossbeam 1a axially, on which a fertilizer box 2 is supported, and the sowing brackets 1c are more than one group, which are arranged at intervals below the crossbeam 1a, on which a seed box 3 is supported, and the opening The trencher support 1d is a parallel four-bar linkage mechanism, installed at intervals below the axial direction of the beam 1a, and correspondingly connected with the sowing support 1c, and the side of the trencher support 1d near the crossbeam 1a is equipped with a disc type fertilization opener 4. The disc type fertilization ditch opener 4 is connected with the fertilizer box 2 through the fertilizer delivery pipe 5, and the side of the di...

Embodiment 2

[0027] In order to enable the planter in embodiment 1 to carry out ditching, fertilization, and seeding operations, the joint operation of weeding and covering soil, suppression, and weeding can be carried out simultaneously. A depth-limiting wheel 15 can be fixedly arranged below the sowing support 1c on one side of the near-disc type fertilization ditch opener 4, and a covering soil suppression combination 16 is fixedly arranged below the sowing support 1c on the side of each depth-limiting wheel 15 away from the beam 1a. A grass-distributing mechanism 17 is fixedly arranged below the sowing support 1c near the side of the beam 1a.

Embodiment 3

[0029] In order to ensure the consistency of the sowing row spacing, markers 18 can be installed at both ends of the beam 1a, and the markers 18 can be controlled by hydraulic pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com