Coffee/espresso machine with a milk froth generating device for the preparation of cappuccino

A technology for espresso coffee and a production device, which is applied to beverage preparation devices, applications, household appliances, etc., can solve problems such as structural consumption, and achieve the effect of low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

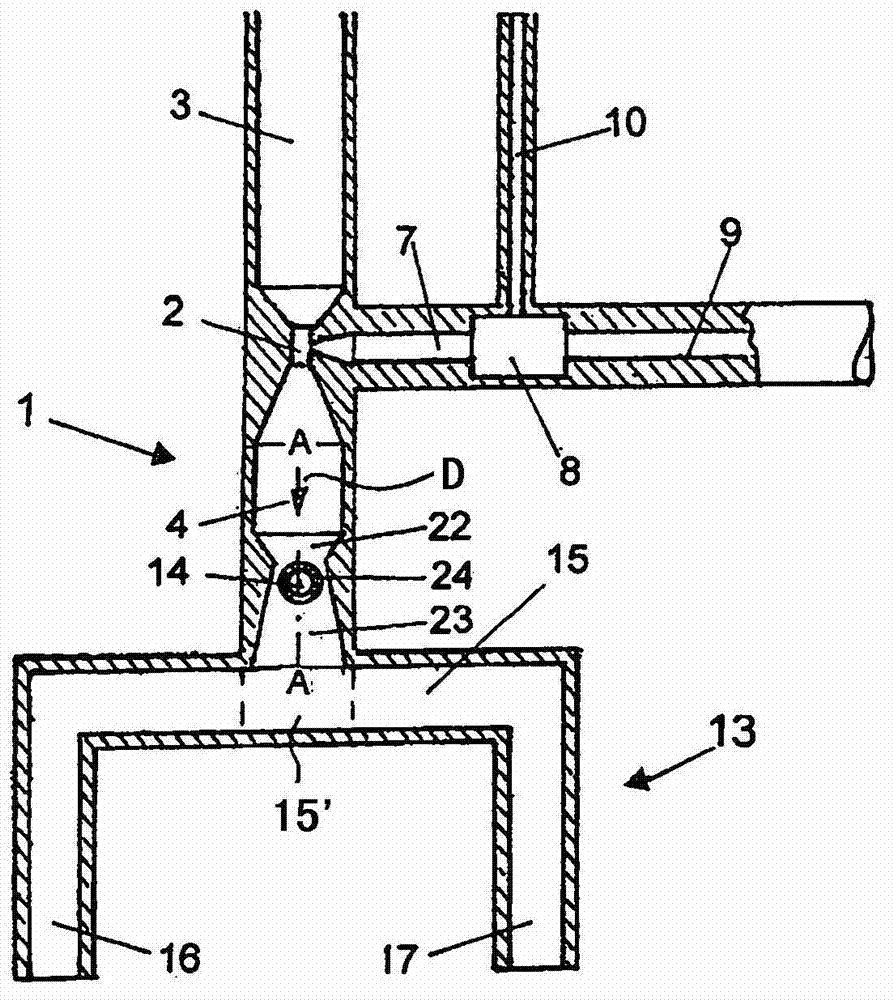

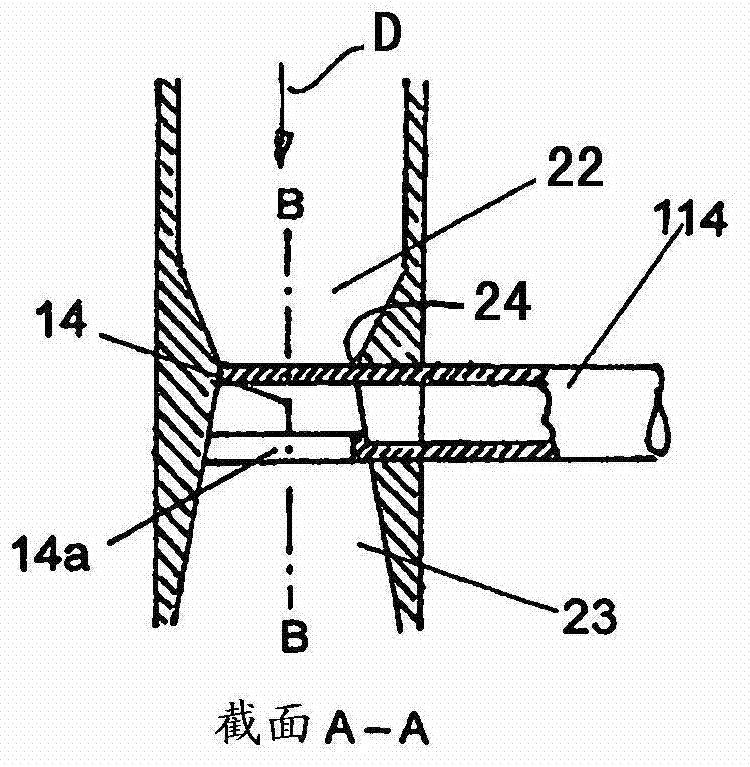

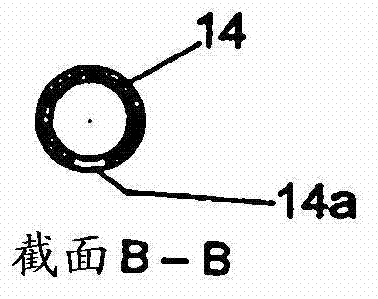

[0025] In the figures, identical components are provided with the same reference numerals.

[0026] figure 1 1 marks the milk froth generating device with a Venturi nozzle 2 which is arranged in the flow channel between the steam feed line 3 and the mixing and froth chamber 4 . A milk-air mixing tube 7 leads to the Venturi nozzle 2 , which is connected to a milk-air premixing chamber 8 . The milk-air premixing chamber 8 is connected on the one hand to the milk inflow line 9 and on the other hand to the air line 10, which can be closed by means of an air valve, not shown, so that the Venturi nozzle 2 is not supplied with milk air if required pre-mix, but only offer milk.

[0027] The basic function of the milk froth generator is to suck the milk-air mixture or milk, but with the air pipe 10 closed, into the Venturi nozzle 2 by means of steam flowing into the steam inlet pipe 3 and to preprocess it into milk froth or milk froth in the froth chamber Heated milk.

[0028] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com