Electric heating hot water bottle

A technology of boiling water bottles and electric heating, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of increasing the packaging and transportation and logistics costs of thermos bottles, troublesome purchase and carrying by consumers, unfavorable inventory and transportation, etc., to achieve novel structure, reduce Small size, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0019] The specific realization of the present invention is described in detail below in conjunction with specific embodiment:

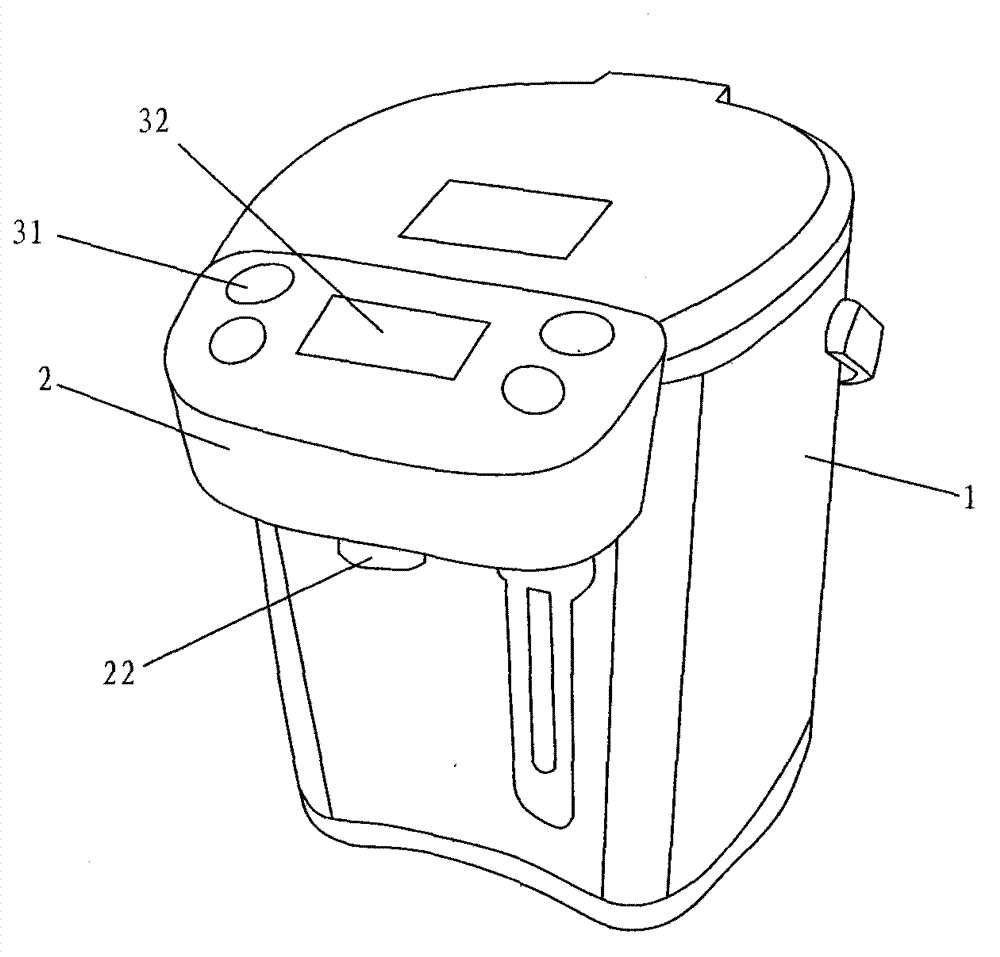

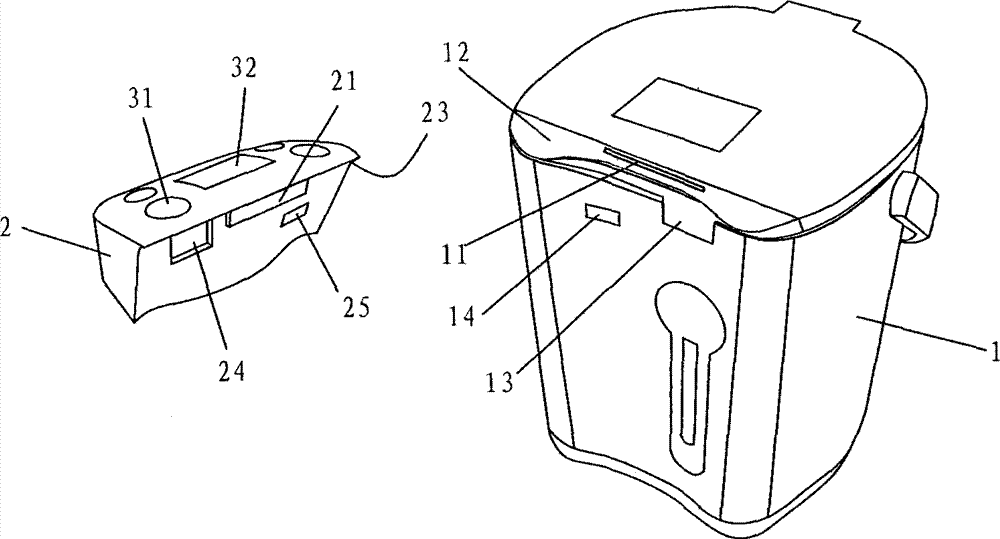

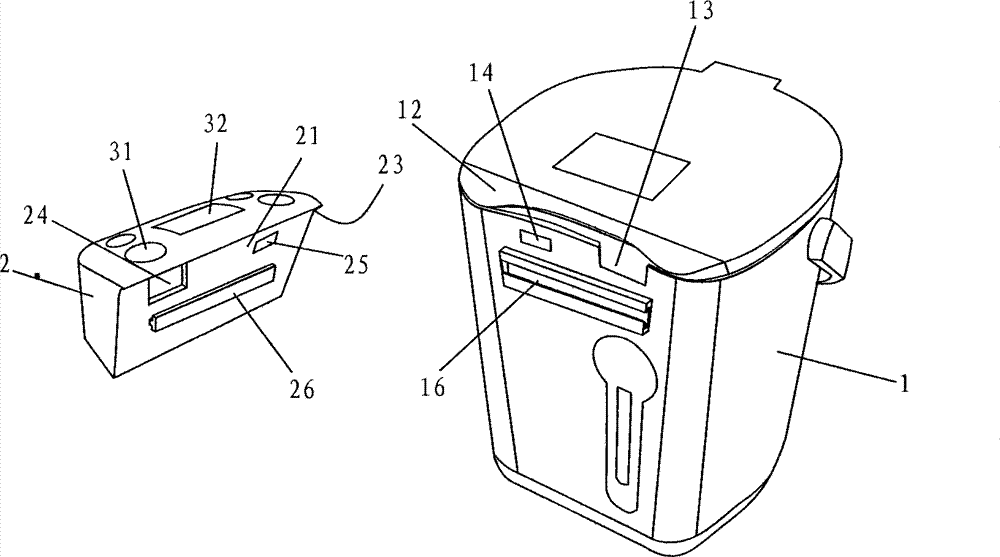

[0020] refer to figure 1 The main structure of the electric heating water bottle provided by the present invention includes a host 1 and a water outlet table 2 with a main board. The host 1 is used for water storage and heating. According to needs, a scale window for observing the water level and a handle for easy lifting can also be added. The water outlet 2 will generally bear multiple functions, wherein its built-in mainboard is used to control the entire water dispen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap