Magnetic bar and iron corrosive isolation bushing

A technology for isolating casings and corrosives, applied in magnetic separation, solid separation, chemical instruments and methods, etc., can solve problems such as low efficiency, poor sealing at shaft seals, and difficulty in maintaining consistent verticality of magnetic rods. remove effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

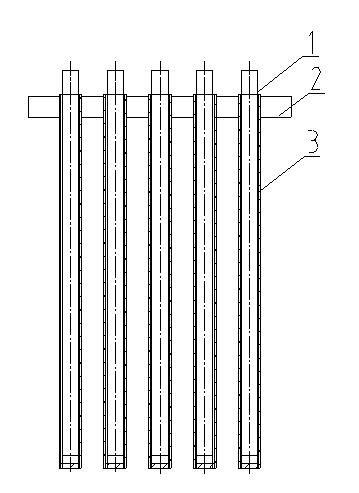

[0016] The stainless steel casing used for separating the permanent magnetic bar and the ferromagnetic substance in the present invention is mainly composed of a stainless steel isolation sleeve fixing plate 2 and a stainless steel isolation sleeve 3, the stainless steel isolation sleeve 3 is fixed on the stainless steel isolation sleeve fixing plate 2, The stainless steel isolation sleeve 3 is sleeved with a magnetic bar 1 .

[0017] The stainless steel isolation sleeve 3 is a non-magnetic stainless steel thin-walled tube to ensure sufficient magnetic strength.

[0018] The inner diameter of the stainless steel isolation sleeve 3 matches the outer diameter of the magnetic rod 1; the permanent magnetic rod 1 used to remove ferromagnetic impurities is inserted into the stainless steel isolation sleeve 3, usually set to the diameter of the permanent magnetic rod 1 The inner diameter of the thin-walled tube is slightly smaller than that of the stainless steel isolating sleeve 3. ...

Embodiment 2

[0022] Such as figure 1 As shown in the schematic diagram of the structure of the present invention, the stainless steel isolating sleeve fixing plate 2 of the present embodiment is distributed and fixed with several stainless steel isolating sleeves 3 parallel to each other, and a whole set of stainless steel isolating sleeves 3 are welded and fixed on the stainless steel thin-walled tube fixing plate 2 An integral structure is formed on the top, and a magnetic rod 1 is sleeved in each stainless steel isolation sleeve 3.

Embodiment 3

[0024] The stainless steel isolation sleeve 3 is a hollow cavity structure with the upper opening and the lower end blocked. The stainless steel isolation sleeve fixing plate 2 is distributed with stainless steel isolation sleeve interfaces, and the upper opening of the stainless steel isolation sleeve 3 is connected to the stainless steel isolation sleeve fixing plate 2. The stainless steel isolation sleeve interface is fixedly connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com