Thermal paste smearing apparatus

A heat dissipation paste and heat sink technology, which is applied in spraying devices, devices for coating liquid on surfaces, coatings, etc., can solve the problem of low efficiency and quality of heat dissipation paste application, affecting the performance and stability of electronic components, and application of heat dissipation paste Quantity and thickness are difficult to grasp and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

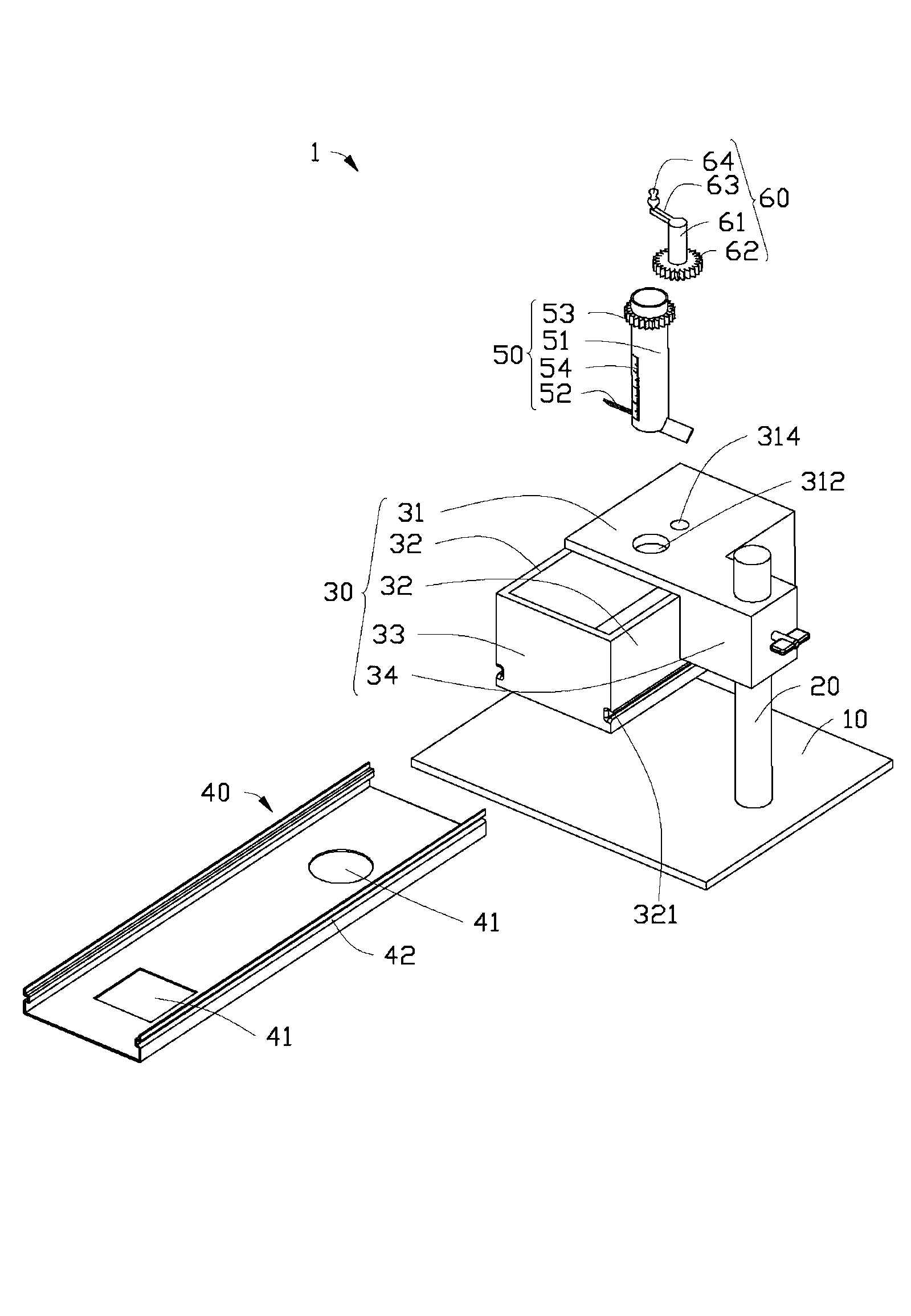

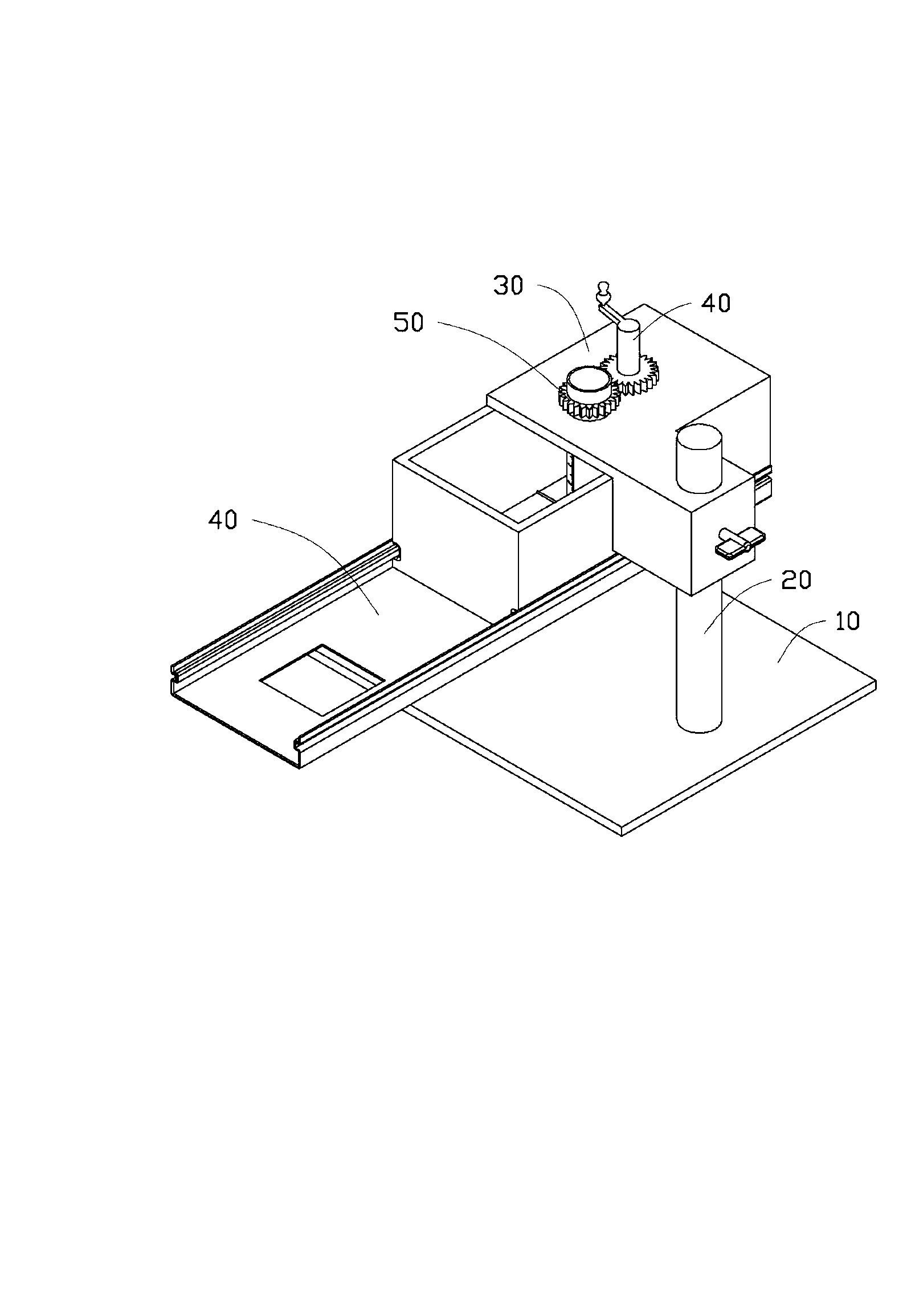

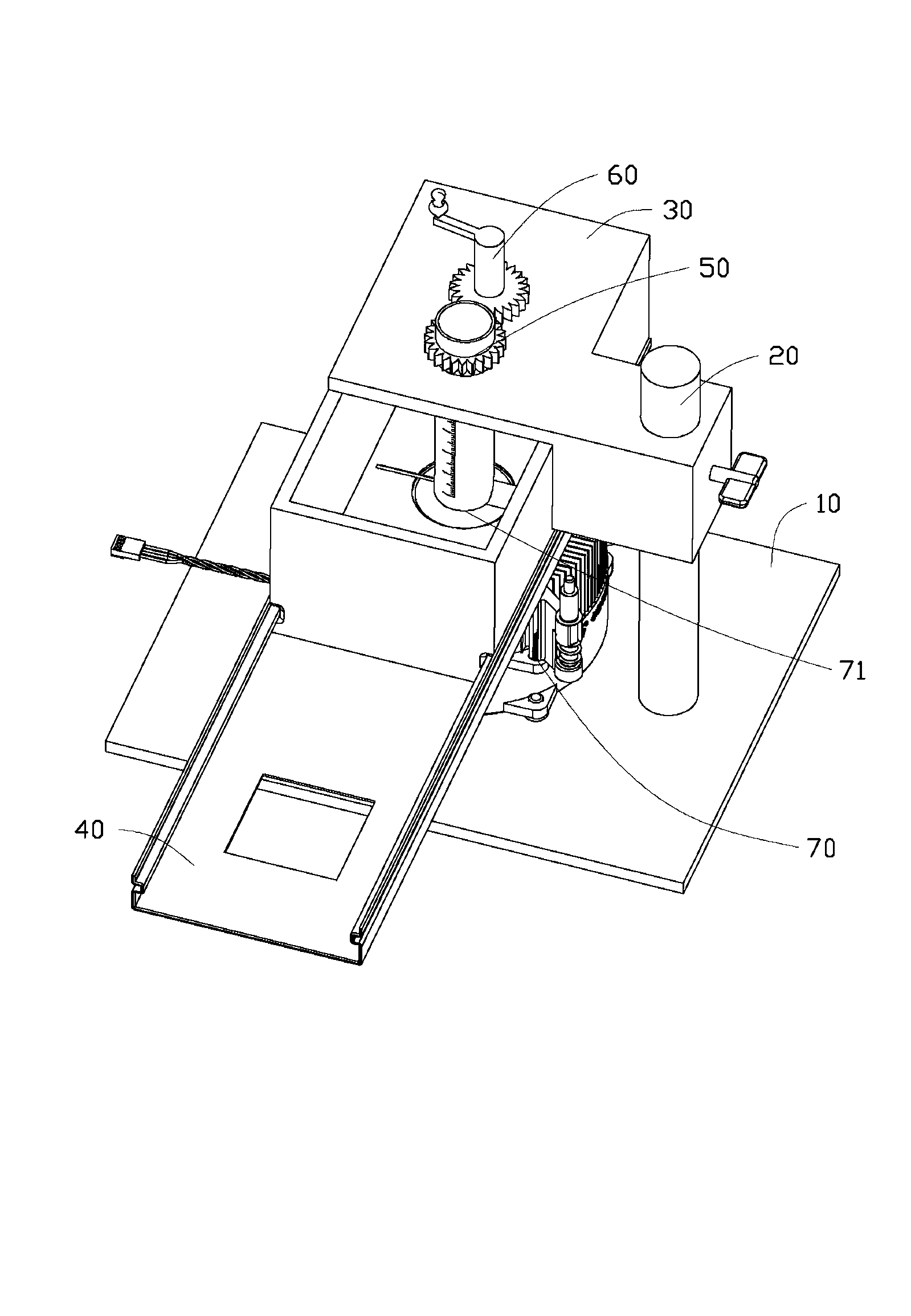

[0019] see figure 1 , in a preferred embodiment, a thermal paste applicator 1 includes a platform 10 for placing a radiator, a support column 20 arranged on the platform 10 , and a bracket fixed on the support column 20 30. A bottom plate 40 arranged at the bottom of the bracket 30 , a top plate 31 arranged at the top of the bracket 30 , a heat dissipation grease conduit 50 opened up and down and hollow, and a rotating handle 60 .

[0020] The platform 10 is used for placing the heat sink to be coated with thermal paste. The support column 20 is located on the side of the platform 10 close to the edge and is perpendicular to the platform 10 .

[0021] The bracket 30 includes two opposite side plates 32, two connecting plates 33 connecting the side plates 32, and the bracket 30 is fixed on the support column 20 so that the bracket 30 is relative to the support column 20 Lifting structure 34 that slides up and down. The side plate 32 , the connecting plate 33 and the top plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com