A small external patch making device

A technology for making a device and a patch, which is applied in the field of devices for making external patches, can solve the problems of poor smearing quality, waste of liquid medicine and the like, and achieves the effects of simple structure, low cost and saving of liquid medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

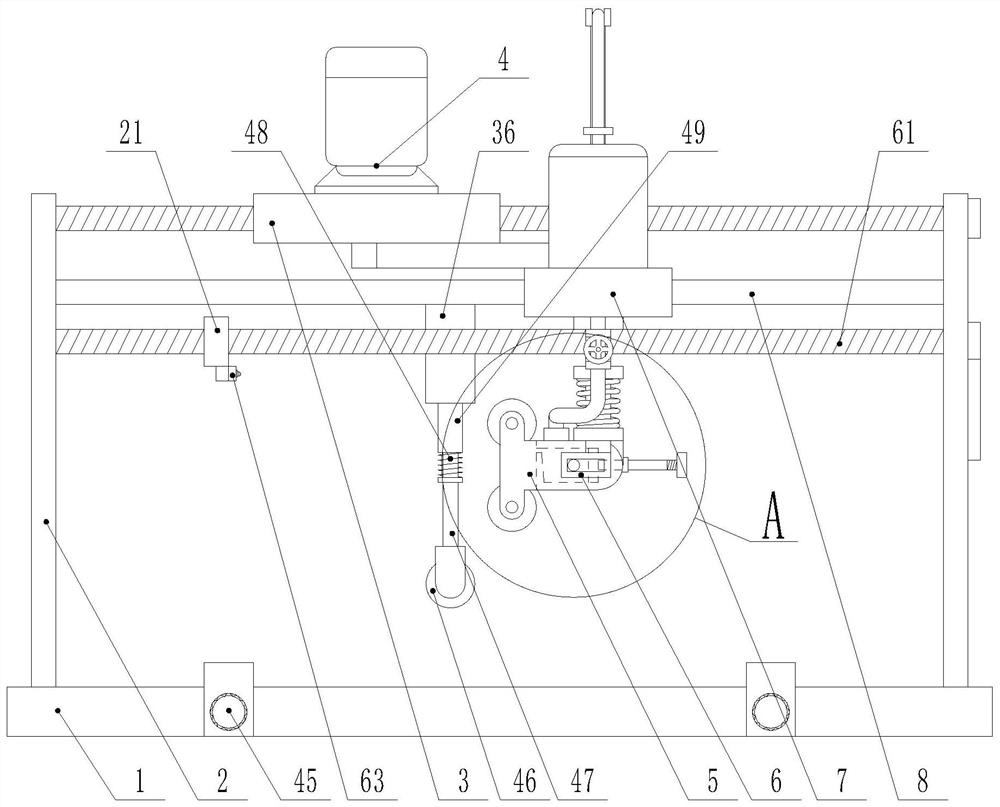

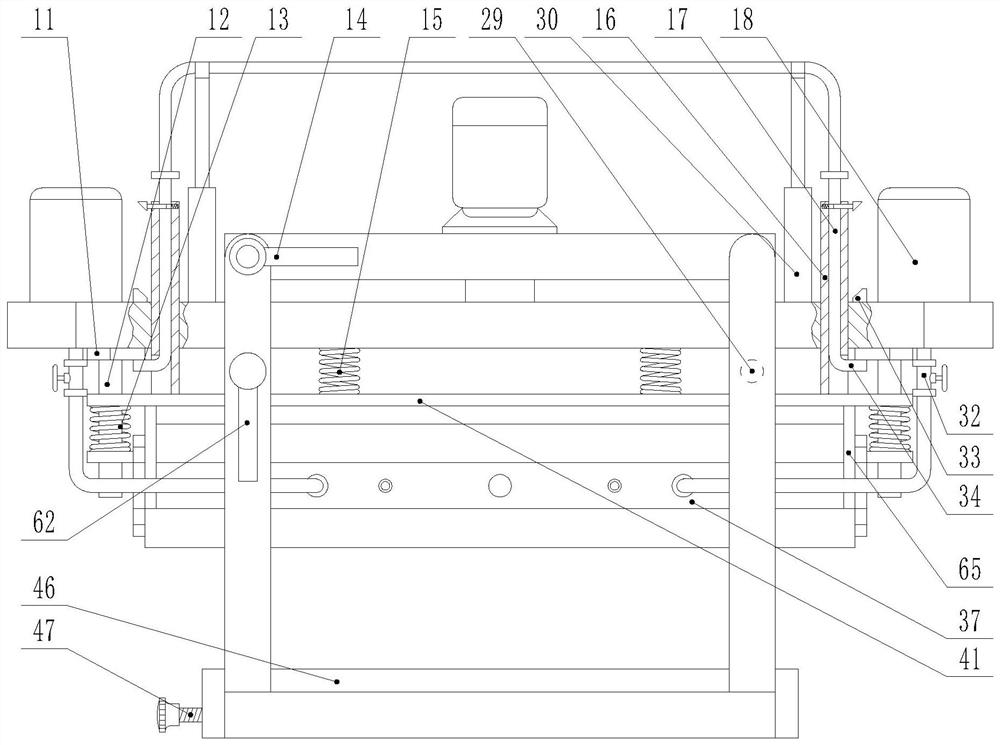

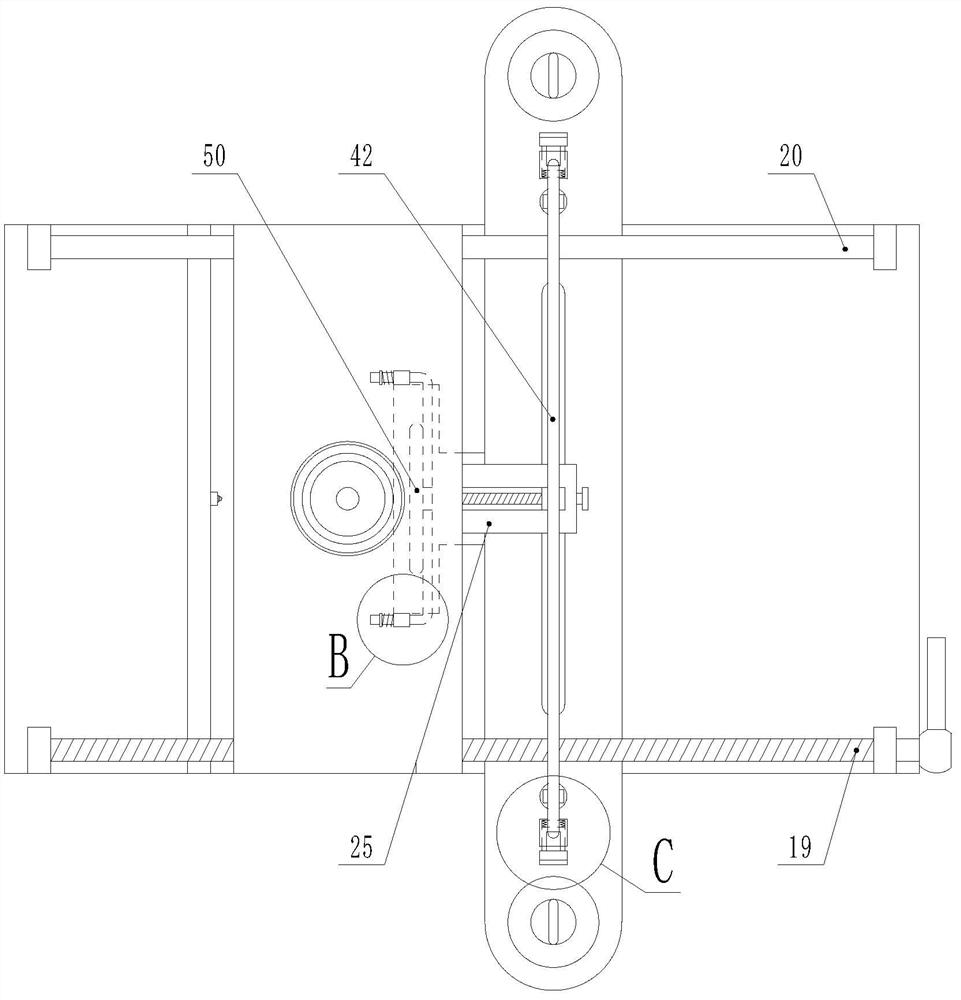

Image

Examples

Embodiment 1

[0049] In the embodiment 1, the interlining board is clamped by two baffle plates 46, and the operation is complicated. In the embodiment 2, as Figure 11 and 12 As shown, the base plate 1 is provided with a cavity with an open lower end, the cavity of the base plate 1 is provided with a two-way screw 60 and a sixth guide rod 57, and the wall at the right end of the cavity of the base plate 1 is provided with a through hole, one end of the two-way lead screw 60 is rotationally connected with the left end wall of the cavity of the bottom plate 1, and the right end passes through the through hole on the right end wall of the bottom plate 1 and is connected with the third handle 58, and the two sides of the two-way lead screw 60 are respectively A sixth guide rod 57 is provided, and the two ends of the two-way lead screw 60 are threadedly connected with a lead screw nut 59 respectively, and a sliding block 55 is provided at both ends of the sixth guide rod 57, and the sliding Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com