Low-temperature disassembling method of touch screen

A touch screen, low-temperature technology, applied in the field of dismantling, can solve the problems of glass panel function panels that cannot be recycled with capacitive screens, and achieve the effect of high-efficiency dismantling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

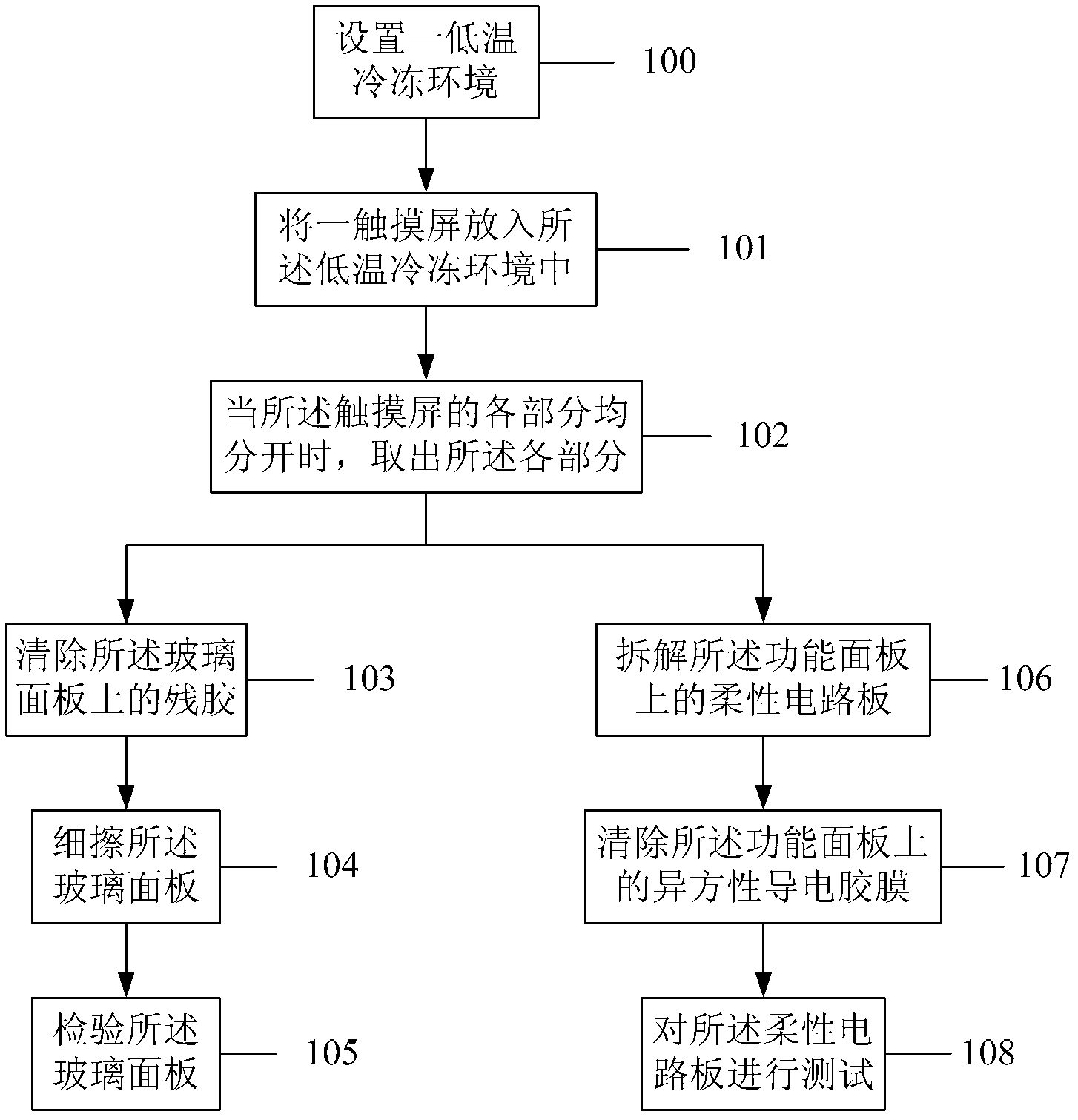

[0027] like figure 1 As shown, the low-temperature dismantling method of the touch screen of the present invention mainly includes the following specific steps:

[0028] Step 100, setting a low-temperature freezing environment. The temperature of the low-temperature freezing environment is controlled at -40°C to -200°C; the low-temperature freezing environment is preferably a liquid nitrogen freezing solution, which has low temperature and stable properties, and is easy to control the low temperature range. Using an ordinary low temperature environment, usually the required freezing time is 1min-5min.

[0029] However, if the touch screen is placed in a liquid nitrogen freezer for freezing, the required freezing time is only 10s-30s, which greatly improves the disassembly speed, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com