Ball grid array (BGA) plant bead furnace

A bead planting furnace and heating plate technology, applied in electric heating devices, auxiliary devices, metal processing, etc., can solve the problems of low efficiency of disposable filter layer and good cleaning effect, achieve stable and reliable humidity control, good cleaning effect, and eliminate damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

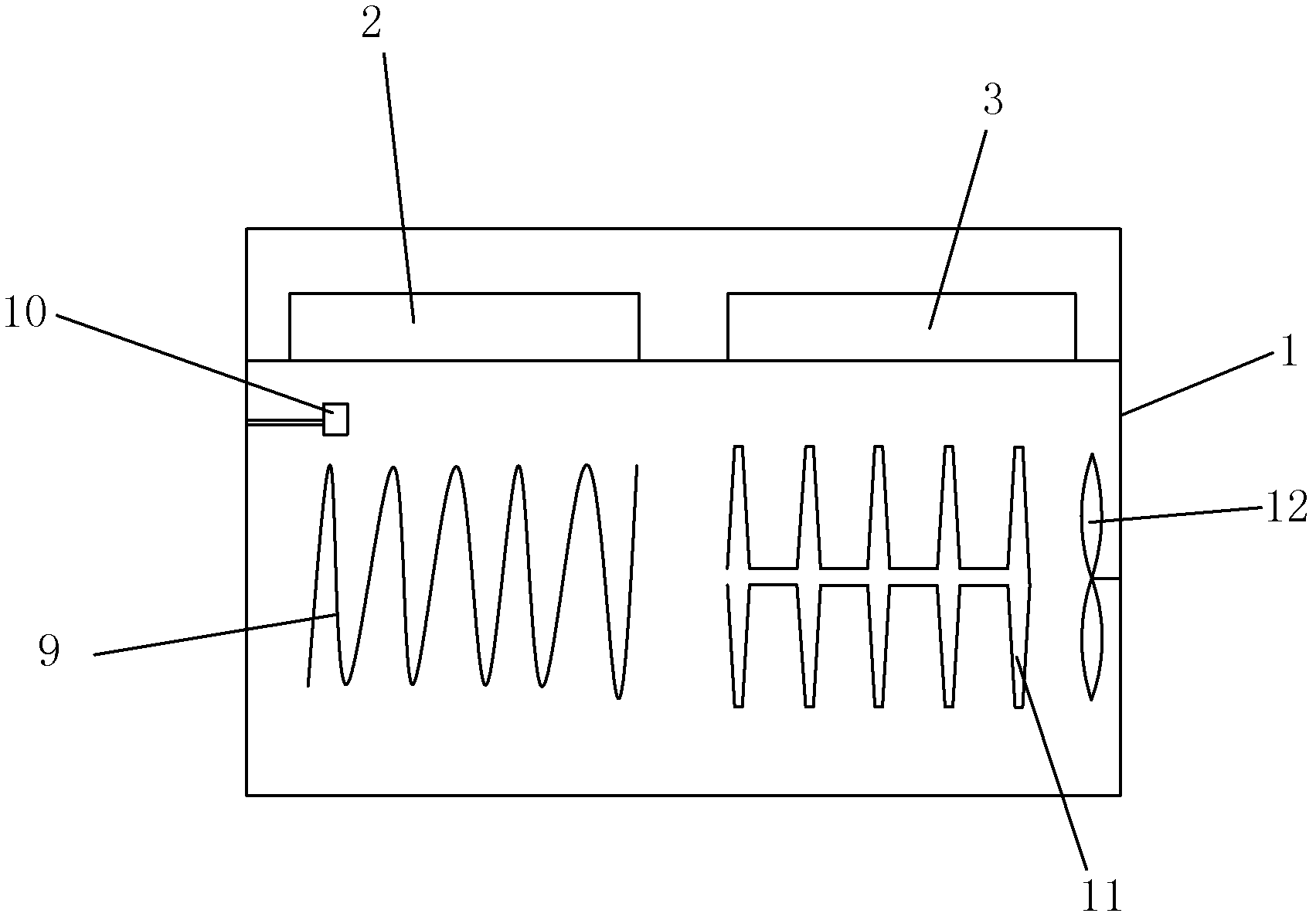

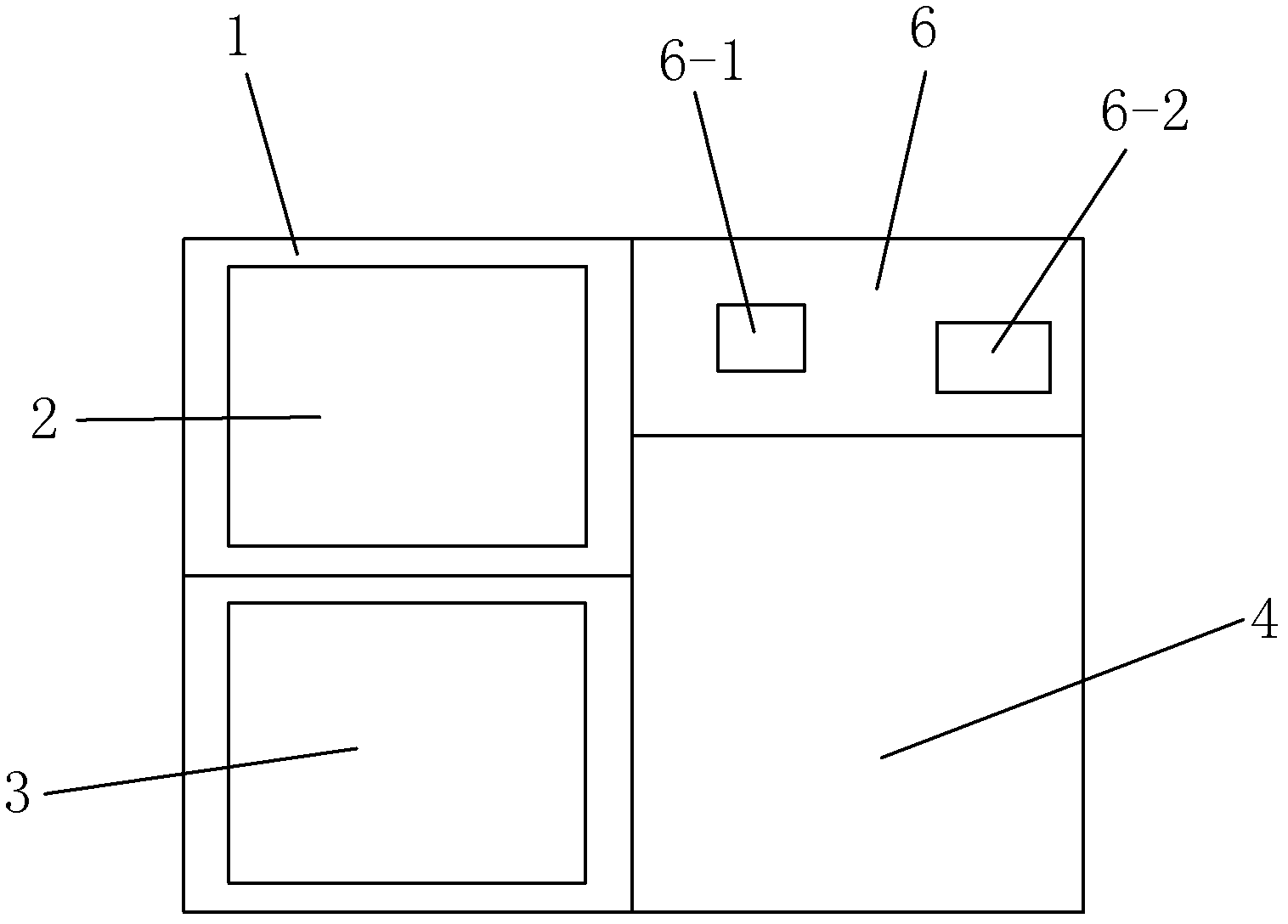

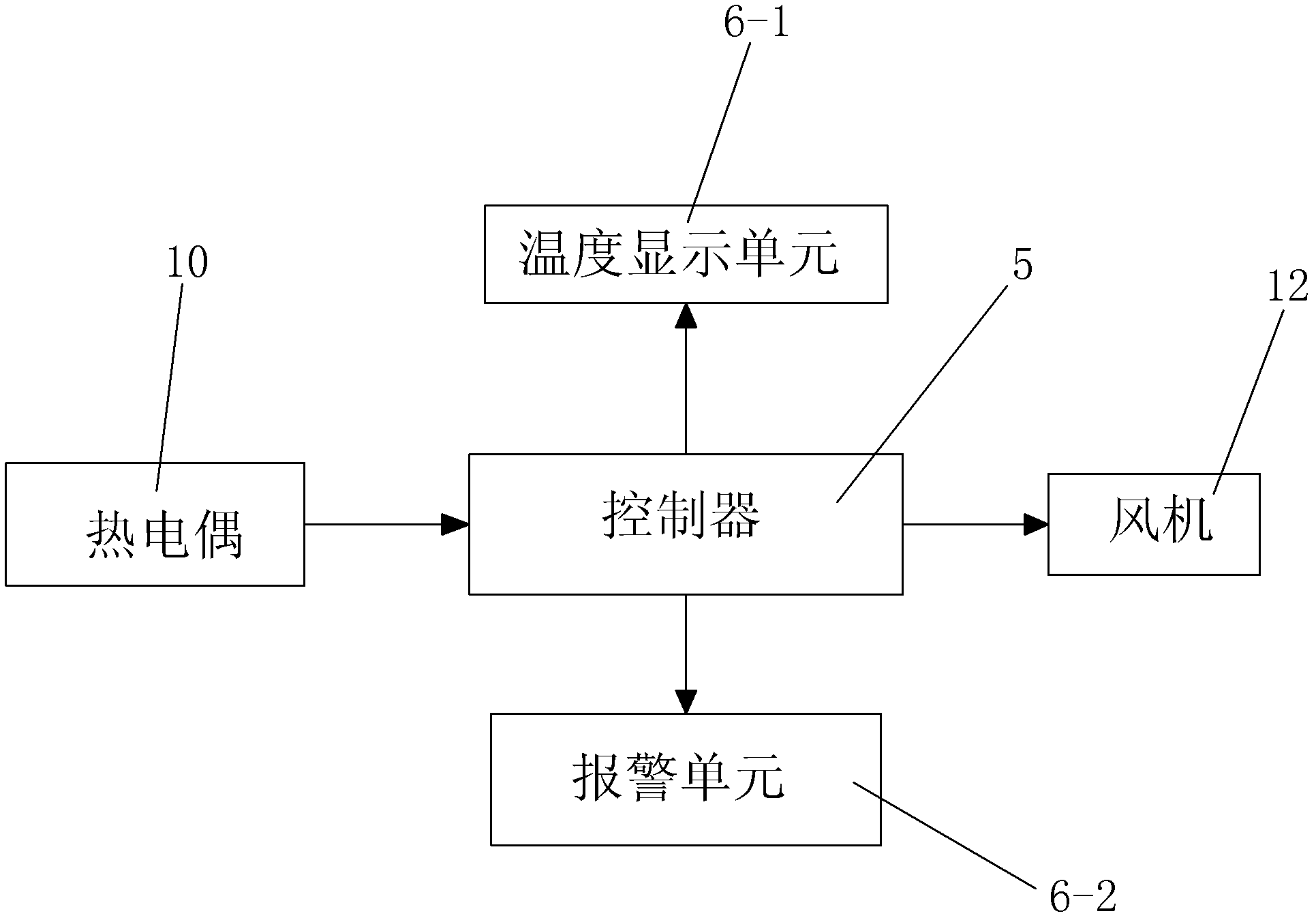

[0022] Such as Figure 1 to Figure 3 As shown, the present invention includes a box body 1 and a heating plate 2, a cooling plate 3 and an operation interface 6 arranged on the box body 1. A heating part and a cooling part are arranged inside the box body 1, and the heating part is used for The heating tube 9 for heating the heating plate 2 and the thermocouple 10 used to detect the current temperature of the heating plate 2 in real time and transmit the detected temperature to the controller 5 are composed of two parts. The heat sink 11 and the fan 12 are gone; the thermocouple 10 and the fan 12 are all connected to the controller 5 and controlled by the controller 5; the controller 5 is also connected and arranged on the operation interface 6 and used for real-time display heating A temperature display unit 6-1 for the temperature on the board 2 and an alarm unit 6-2 for alarming after the bead welding is completed.

[0023] In this embodiment, the alarm unit 6-2 is an audi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com