Adjustable wrench head of torque wrench

A technology of torque wrench and wrench head, which is applied to wrenches, screwdrivers, manufacturing tools, etc. It can solve the problems of low work efficiency and achieve the effects of high work efficiency, convenient and stable connection, and labor-saving rotation of the handwheel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

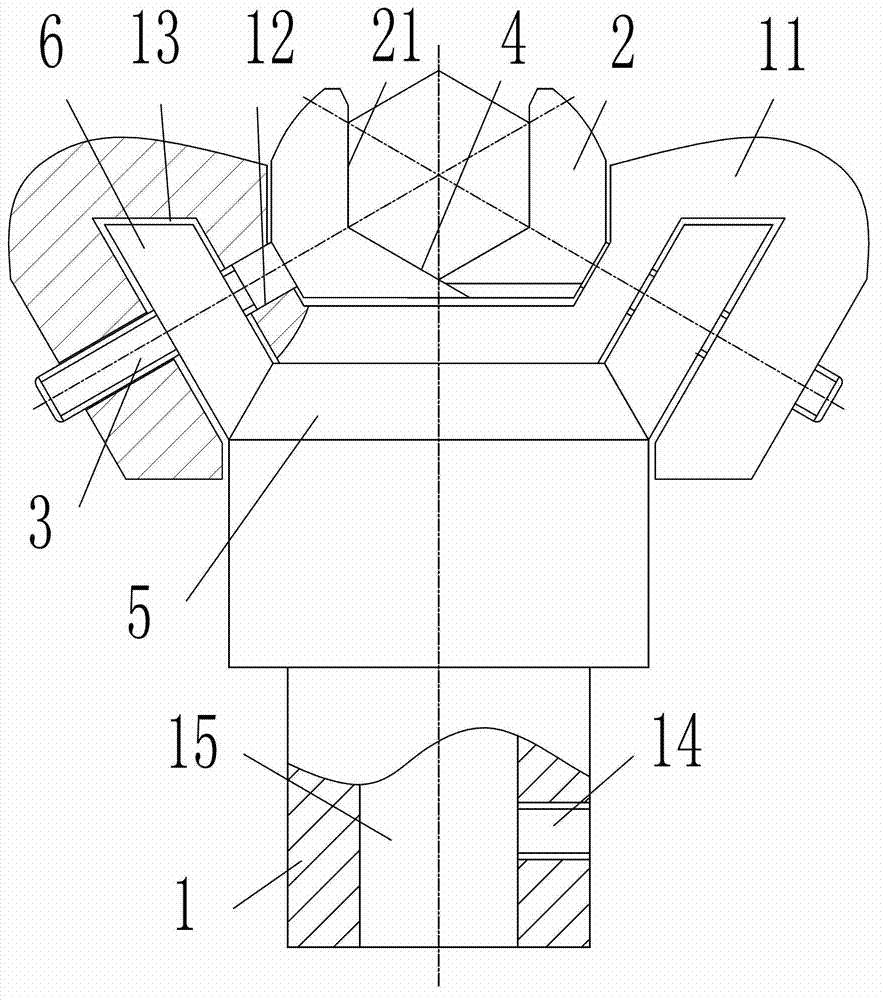

[0016] Embodiment 1, as attached figure 1 Shown: an adjustable wrench head of a torque wrench, including a connecting rod 1 with two symmetrical bumps 11 at one end, two wrenching rods located between the two bumps 11 and symmetrical to an axial section of the connecting rod 1 Claw 2 and two adjustment levers 3; two pull claws 2 opposite sides are respectively provided with a V-shaped notch 21; the angle between the two sides of the V-shaped notch 21 is 120 degrees; One side is respectively parallel to an axial section of the connecting rod 1; the other side of the two V-shaped notches 21 forms the closed end 4; each of the two protrusions 11 has a rod hole whose diameter matches the outer diameter of the adjusting rod 3 12. One end of each adjustment rod 3 passes through the rod hole 12 of a projection 11 and is fixedly connected to a pulling claw 2, and the angle bisector of the angle between the two sides of the V-shaped notch 21 and one of the adjustment rod 3 The shaft s...

Embodiment 2

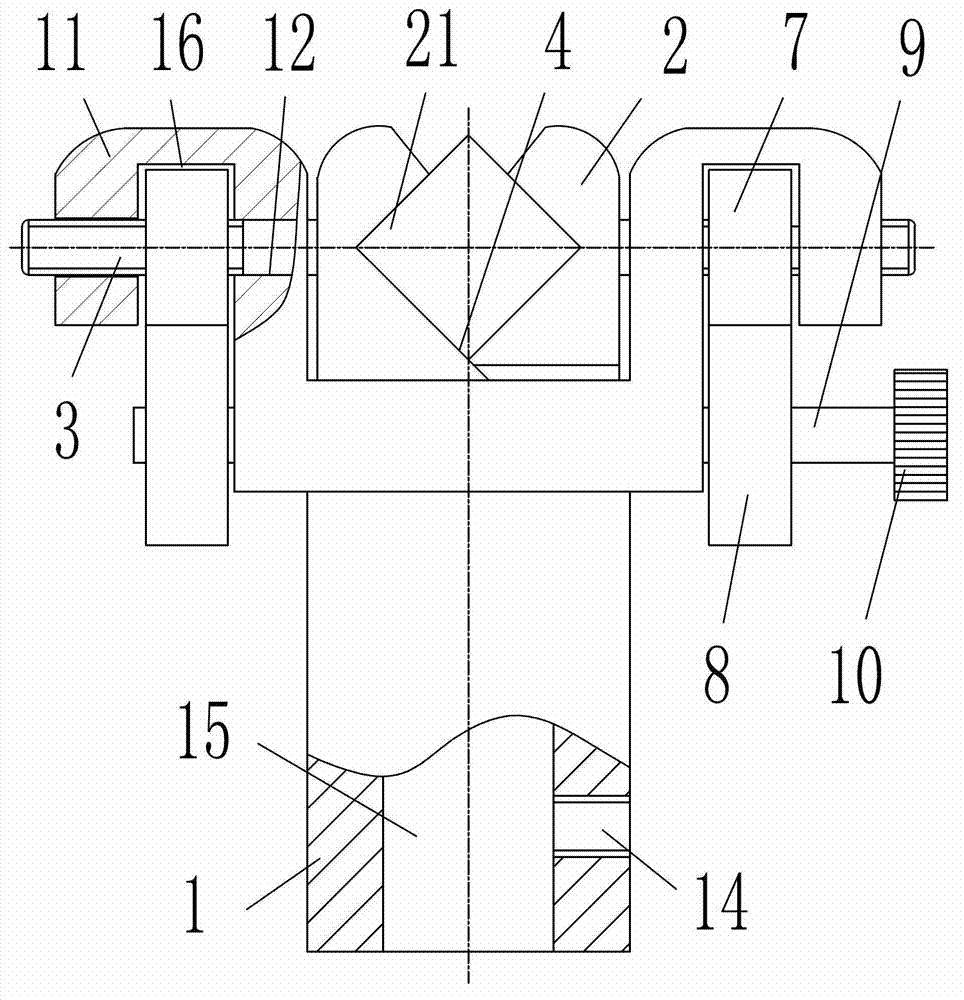

[0021] Embodiment 2, as attached figure 2 Shown: an adjustable wrench head of a torque wrench, including a connecting rod 1 with two symmetrical bumps 11 at one end, two wrenching rods located between the two bumps 11 and symmetrical to an axial section of the connecting rod 1 Claw 2 and two adjusting rods 3; two opposite sides of pulling claw 2 are respectively provided with a V-shaped notch 21; the angle between the two sides of V-shaped notch 21 is 90 degrees; both sides of V-shaped notch 21 The angle bisector of the included angle between the sides is perpendicular to the axis of the adjusting rod 3; the length of one side of the V-shaped notch 21 is less than the length of the other side; the other side of the two V-shaped notches 21 forms the closed end 4 ; Two projections 11 each have a rod hole 12 whose diameter is matched with the outer diameter of the adjustment rod 3; one end of each adjustment rod 3 passes through the rod hole 12 of a projection 11 and is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com