Wrench special for nuts of main heat transfer pipe support post of heavy water reactor

A technology of heat transfer and support and hanger, applied in the directions of wrenches, screwdrivers, wrenches, etc., can solve the problems of large radiation dose, long operation time, difficult operation, etc., to improve efficiency, reduce radiation dose, and ensure reliability. and the effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following is attached figure 1 to attach Figure 6 and Examples further describe the present invention.

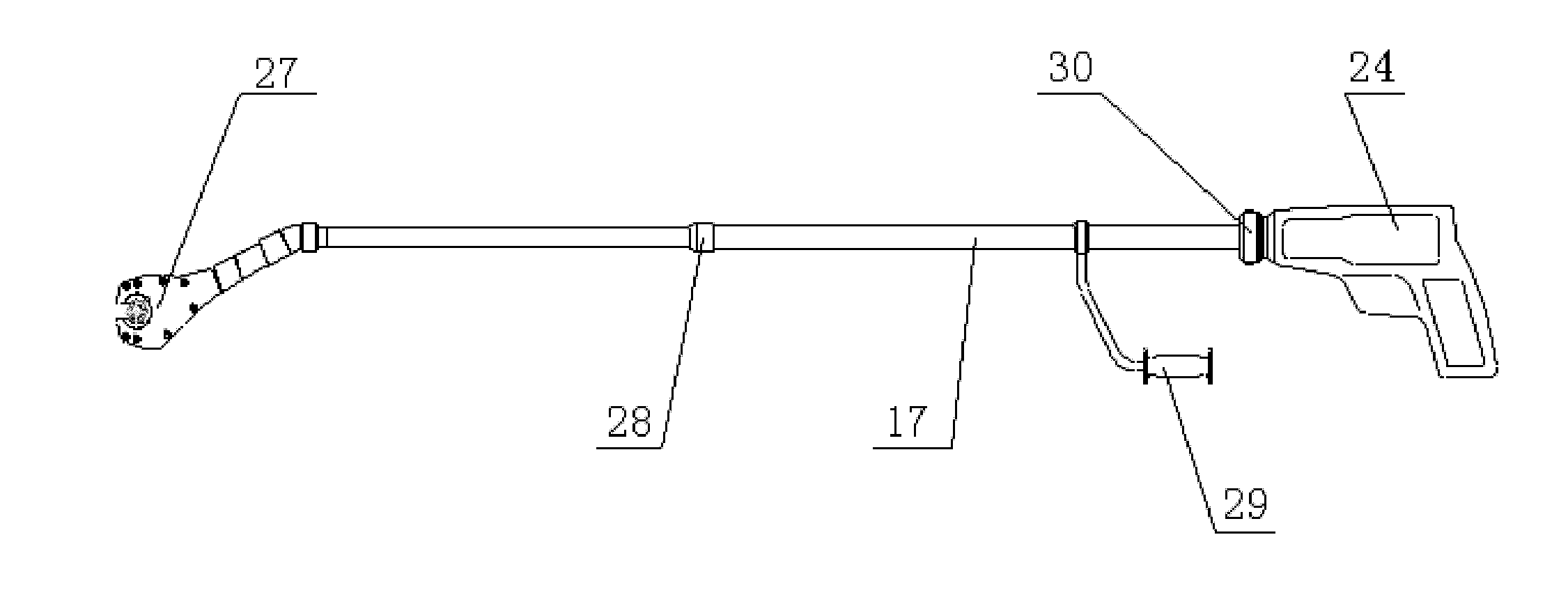

[0032] A special wrench for the support and hanger nut of the main heat transfer pipe of a heavy water reactor, including a rotary sleeve transmission system 27, a sliding pull rod device 28, an operating handle 29, and a drive system;

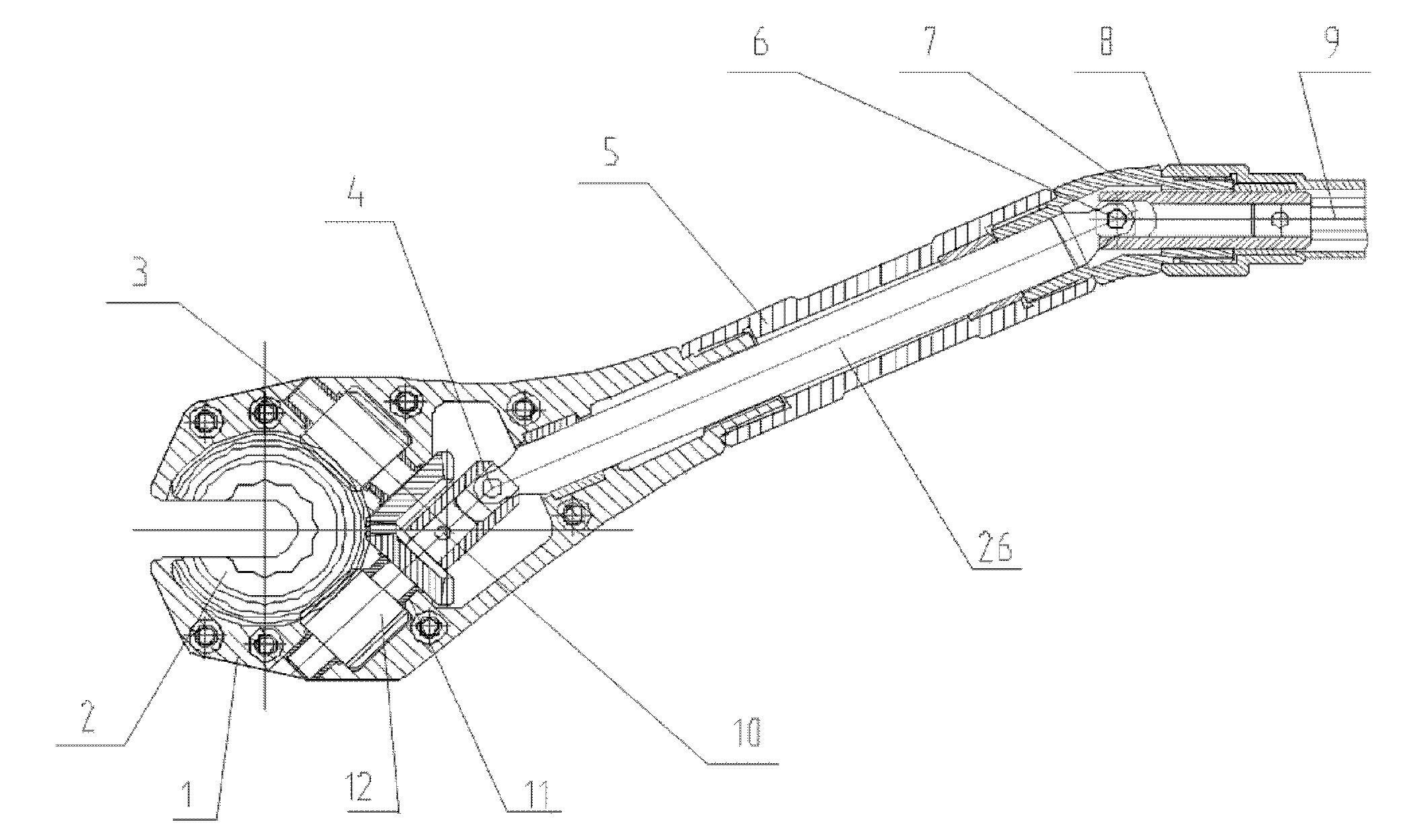

[0033] The rotary sleeve transmission system 27 includes a box body 1, a rotary worm gear sleeve 2, a first worm bevel gear shaft 3, a second worm bevel gear shaft 12, a first universal joint 4 and a connecting shaft 26;

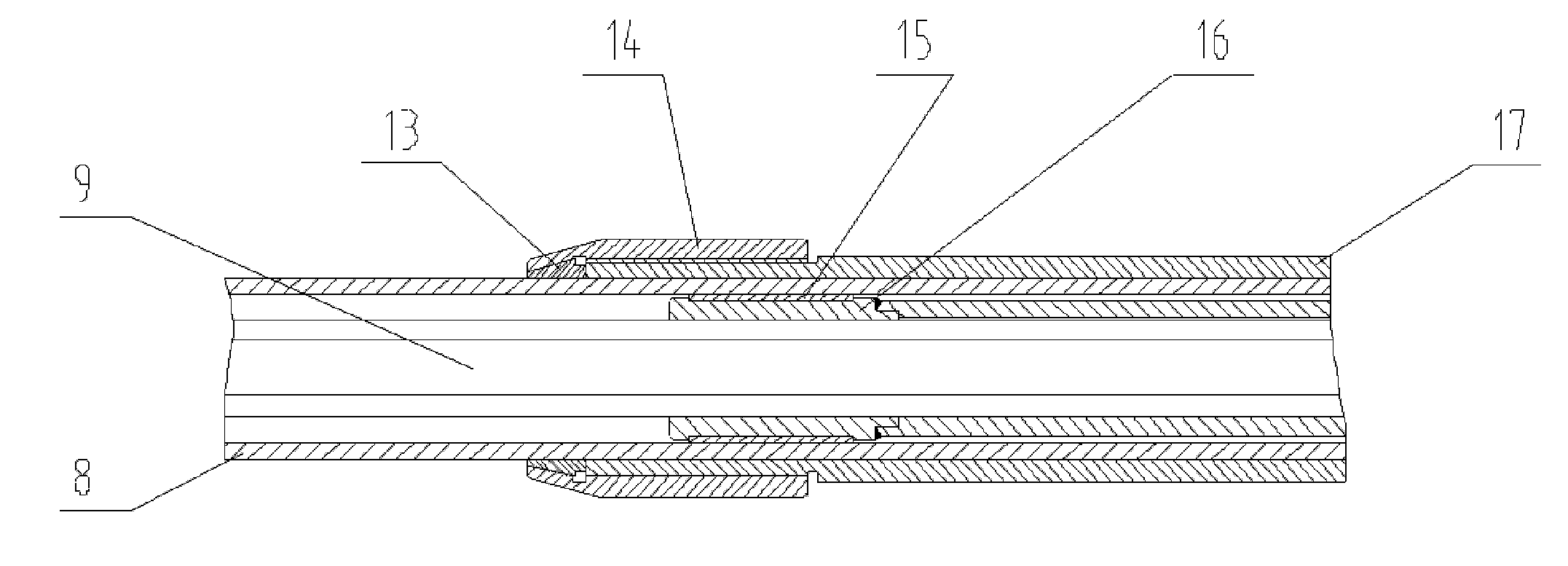

[0034] The box body 1 is an upper and lower split structure, and the upper and lower parts of the box body 1 are fixed by screws; one end of the box body 1 is provided with an opening, and a cylindrical groove is opened on the box body adjacent to the opening; the rotary worm gear The sleeve 2 adopts the integrated structure of the sleeve and the outer worm gear of the sleeve. The rotary worm gear sleeve is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com