Control method for double helix differential definite quantity conveyer system

A double-screw conveyor and conveying control technology, applied in conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of weighing failure, long weighing operation time, interruption of automatic weighing operation, etc. The effect of meeting the requirements of the production process, adapting to industrial production and meeting the precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

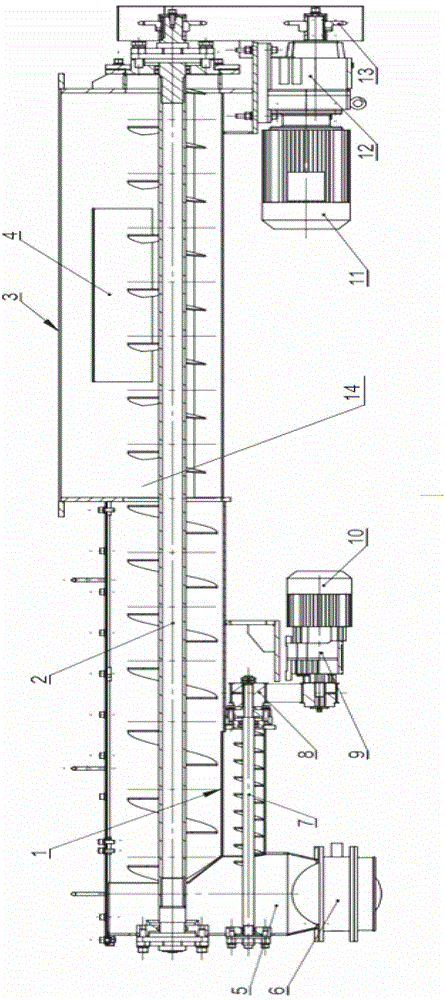

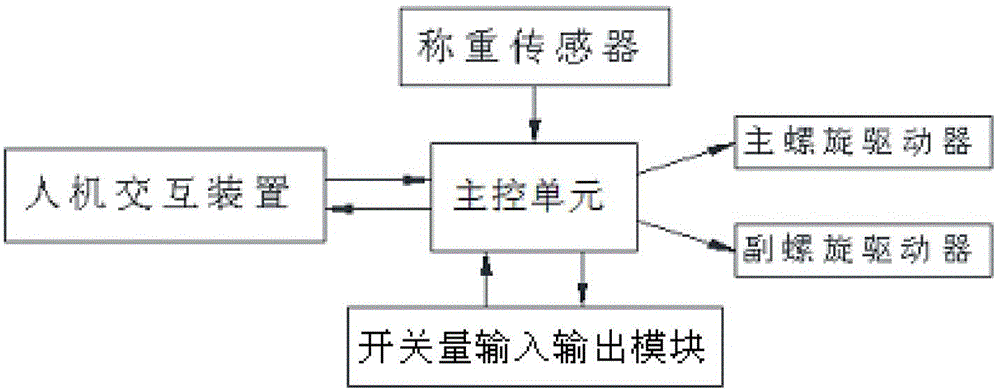

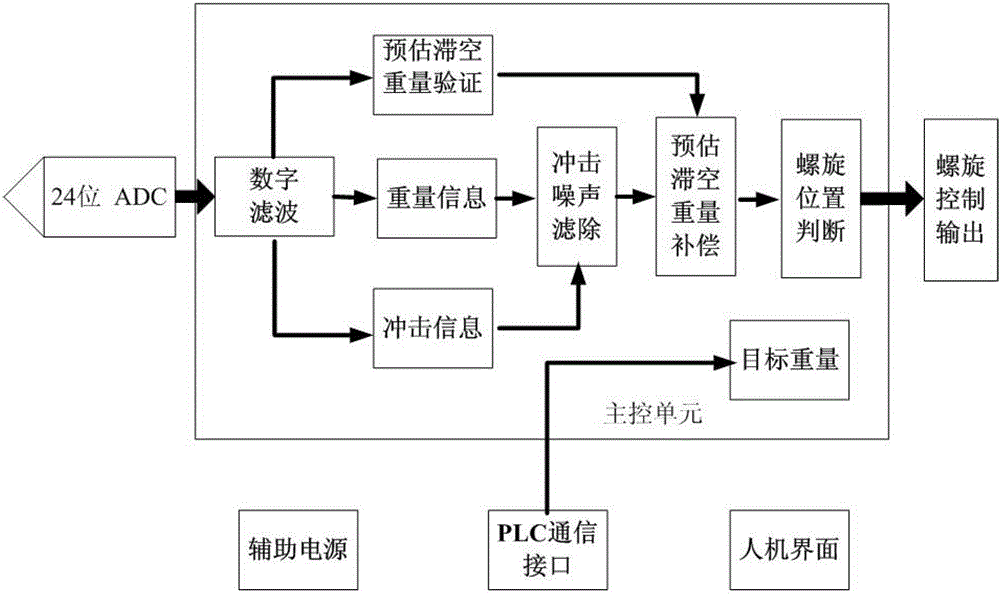

[0026] A double-screw differential quantitative conveying system is composed of a double-screw conveyor connected to a double-screw differential quantitative control device. Such as figure 1 As shown, the twin-screw conveyor includes a fuselage 14, a feed inlet 3, a discharge outlet 5, a main screw 2, a main screw motor 11, a secondary screw 7 and a secondary screw motor 10, and the feed inlet is arranged on one side of the fuselage Above, the main screw is installed horizontally inside the fuselage, and the main screw motor is installed under the fuselage on the side of the feed inlet. The main screw motor is connected to the main screw through the main screw reducer 12 and the sprocket 13. The side wall of the fuselage below is provided with the observation window 4 that can observe the feeding situation. The discharge port is set under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com