Ultra-large rope capacity coiling drum

A super-large and reel technology, applied in the field of super-large rope-capacity reels, can solve problems such as the influence of the height of the low-speed bearing of the reducer, the impact on the safety performance of lifting equipment, the increase of the reel and the diameter of the reel, etc., to achieve production Low cost, solve the problem of messy rope, and improve the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

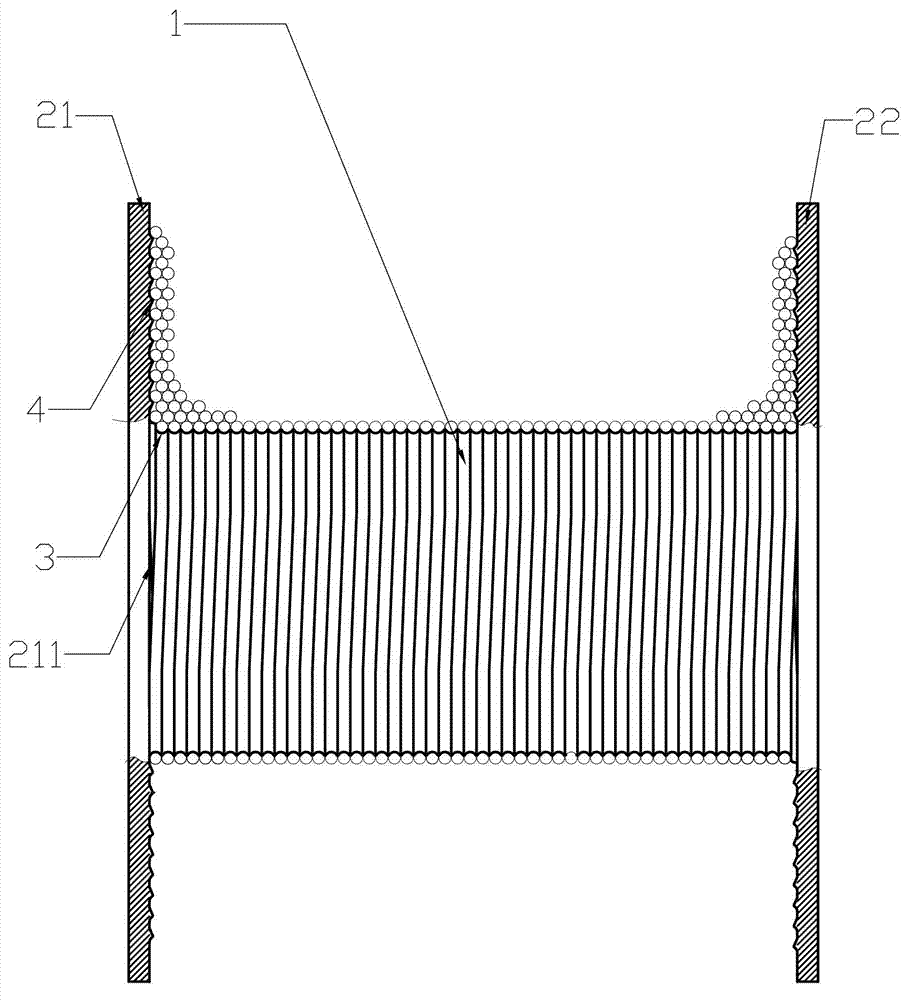

[0038] The reel is used for hoisting by the hoisting mechanism, and the technical parameters are as follows:

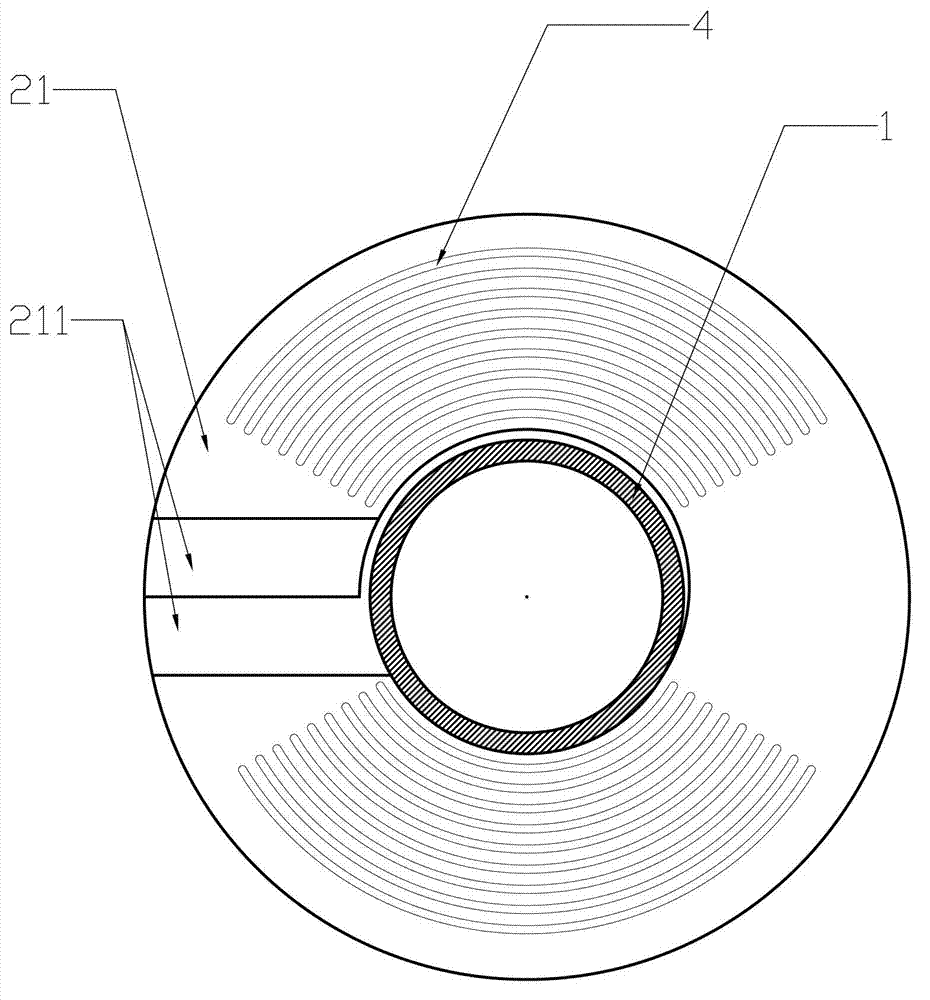

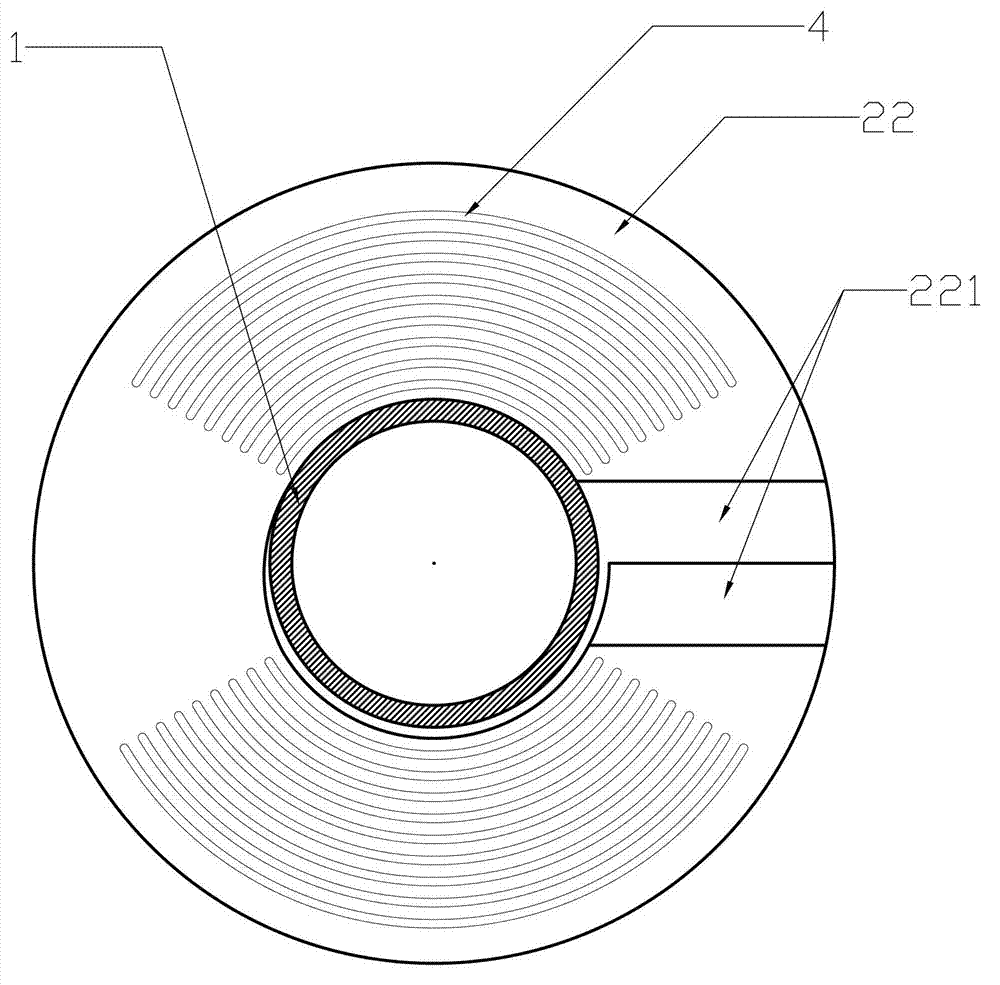

[0039] (1), wire rope: Left rotation, average speed 130m / min;

[0040] (2) Rope groove: Double-broken rope groove, right-handed, with a boss on the inner layer of the gear plate, the pitch of the 6 consecutive rope grooves close to the gear plate is 25mm, and the pitch of the other rope grooves is 25.2mm;

[0041] (3), the first layer winding diameter:

[0042] (4), the number of wire rope winding layers: 16 layers;

[0043] (5), rope capacity: 1050m;

[0044] (6), the maximum lifting force of the winch: 80KN;

[0045] The drum has been hoisted 20 times in a row with no load on site. During the test, the wire rope was wound stably, and the on-site rope arrangement has reached 17 layers.

[0046] The drum has been hoisted for 20 consecutive times with a load of 50% on site. During the test, the wire rope was wound stably. The on-site rope arrangement has reache...

Embodiment 2

[0049]The reel is used for hoisting by the hoisting mechanism, and the technical parameters are as follows:

[0050] (1), wire rope: Left rotation, average speed 60m / min;

[0051] (2) Rope groove: double-broken rope groove, right-handed, with a boss on the inner layer of the gear plate, the pitch of the 6 consecutive rope grooves near the gear plate is 27mm, and the pitch of the other rope grooves is 27.4mm;

[0052] (3), the first layer winding diameter:

[0053] (4), the number of wire rope winding layers: 15 layers;

[0054] (5), rope capacity: 900m;

[0055] (6), the maximum lifting force of the winch: 100KN;

[0056] The drum has been hoisted 20 times in a row with no load on site. During the test, the wire rope was wound stably, and the on-site rope arrangement has reached 16 layers.

[0057] The drum has been hoisted for 20 consecutive times with a load of 50% on site. During the test, the wire rope was wound stably. The on-site rope arrangement has reached 16 l...

Embodiment 3

[0060] The reel is used for hoisting by the hoisting mechanism, and the technical parameters are as follows:

[0061] (1), wire rope: Left rotation, average speed 80 / min;

[0062] (2) Rope groove: double-broken rope groove, right-handed, with a boss on the inner layer of the gear plate, and the pitch of the 6 consecutive rope grooves close to the gear plate is 29.2mm, and the pitch of the other rope grooves is 29.6mm;

[0063] (3), the first layer winding diameter:

[0064] (4), wire rope winding layers: 18 layers;

[0065] (5), rope capacity: 1100m;

[0066] (6), the maximum lifting force of the winch: 100KN;

[0067] The drum has been hoisted 20 times in a row with no load on site. During the test, the wire rope was wound stably, and the on-site rope arrangement has reached 19 layers. There was no rope disorder, grinding or biting.

[0068] The drum has been subjected to 20 consecutive lifting tests with a load of 50% on site. During the test, the wire rope was wound...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com