Method for improving washing and separating efficiency of polyphenylene sulfide particles

A technology of polyphenylene sulfide and separation efficiency, applied in the field of washing, can solve the problems of increasing the number of washing times, increasing the amount of detergent, and poor washing and separation effects, so as to reduce manpower consumption, high material pressure, avoid loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

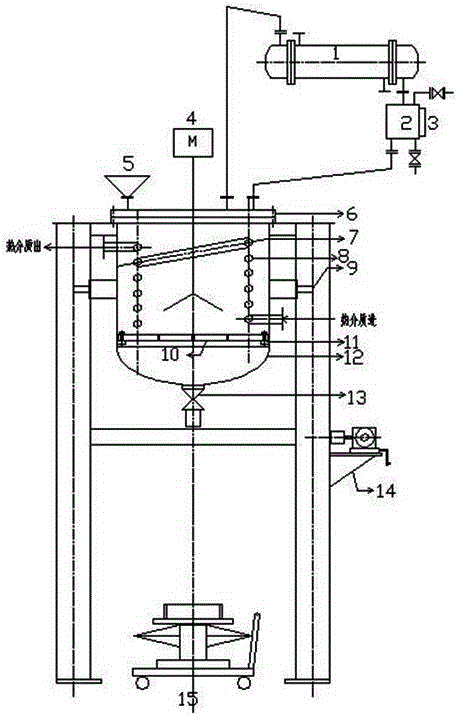

Image

Examples

Embodiment

[0027] In the synthesis of polyphenylene sulfide, the product cannot reach a uniform molecular weight, and the particle size of the obtained polymer is also different, but the particle size of more than 95% of the polyphenylene sulfide particles is above 75 μm, and the remaining part of the polyphenylene sulfide The phenylene sulfide particles are smaller than 75 μm. During the synthesis process, sodium chloride particles more than twice the total mass of polyphenylene sulfide will be produced by-product. The particle size of sodium chloride is less than 20 μm, and sodium chloride is soluble in water and can be removed by washing with water.

[0028] A certain batch of crude product synthesized was subjected to preliminary solid-liquid separation with a vibrating sieve. Since polyphenylene sulfide and by-products are mixed together, it is a sticky particle. Such polyphenylene sulfide particles were equally divided into several samples.

[0029] For the first sample, use as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com