Etching method

A technology of etching and etching solution, which is applied in the field of chemical etching processing, and can solve problems such as affecting visual effects and processing workpieces with poor hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

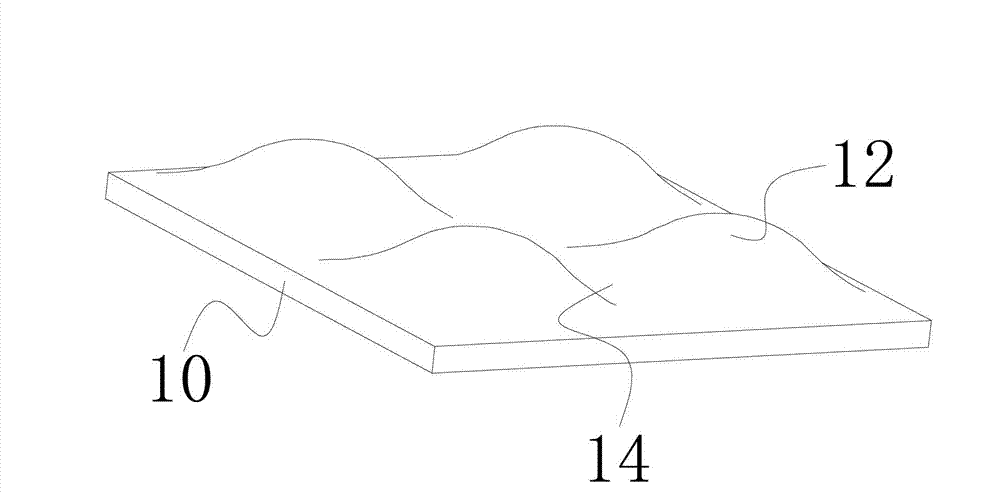

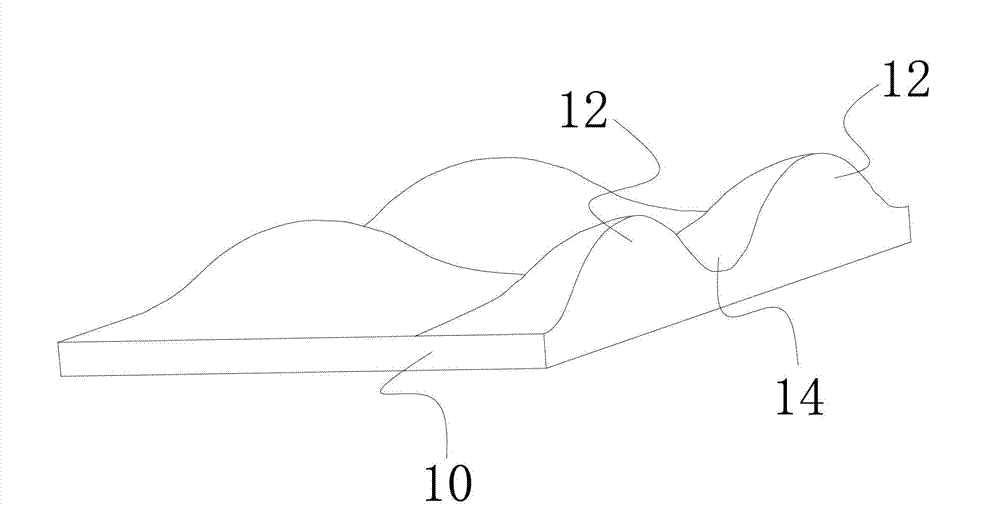

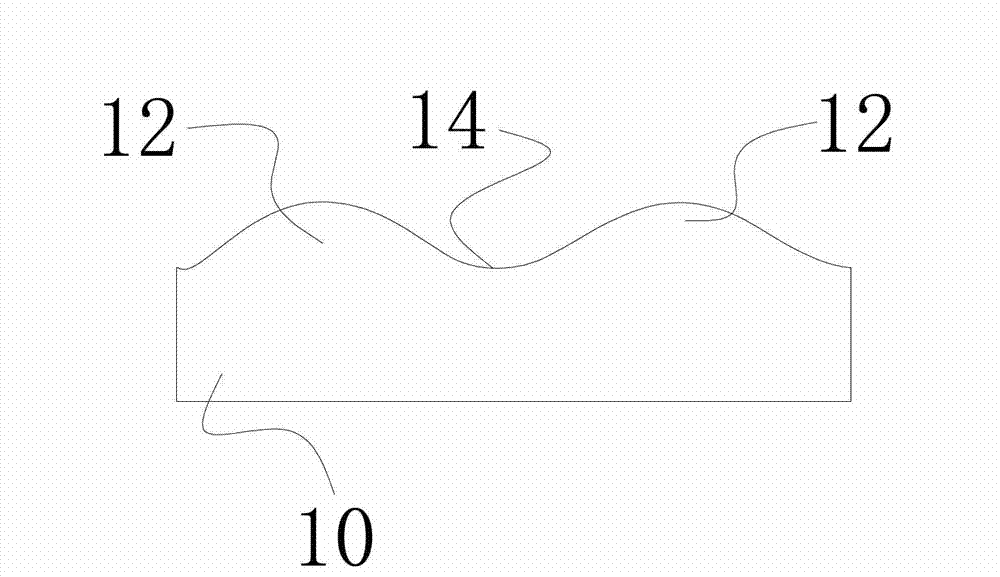

[0029] A kind of etching method, comprises the following steps:

[0030] (1) Mask the workpiece: apply several corrosion-resistant adhesives on the surface of the workpiece. The corrosion-resistant adhesive is a square structure with a thickness of 10 μm, and there is an uncoated corrosion-resistant adhesive between two adjacent corrosion-resistant adhesives. The glue gap, the width of the gap is 1 / 4 of the side length of the square corrosion-resistant glue;

[0031] (2) Put the masked workpiece into the etching machine for initial etching. The pressure of the etching solution a sprayed from the nozzle of the etching machine is 1.8 psi, and the etching time is 3 minutes. The etching solution a contains FeCl 3 , water and NaCl, and FeCl 3 , the mass ratio of water and NaCl is FeCl 3 : Water: NaCl=5:35:1;

[0032] (3) Remove the film from the workpiece after the initial etching: put the workpiece after the initial etching in NaOH solution, and remove the corrosion-resistant g...

Embodiment 2

[0037] A kind of etching method, comprises the following steps:

[0038] (1) Masking the workpiece: coating a number of corrosion-resistant adhesives on the surface of the workpiece. The corrosion-resistant adhesive is a square structure with a thickness of 40 μm, and there is an uncoated corrosion-resistant adhesive between two adjacent corrosion-resistant adhesives. The glue gap, the width of the gap is 1 / 3 of the side length of the square corrosion-resistant glue;

[0039] (2) Put the masked workpiece into the etching machine for initial etching, the pressure of the etching solution a sprayed from the nozzle of the etching machine is 0.3psi, and the etching time is 10min, wherein the etching solution a contains FeCl 3 , water and NaCl, and FeCl 3 , the mass ratio of water and NaCl is FeCl 3 : Water: NaCl=35:35:1;

[0040] (3) Remove the film from the workpiece after the initial etching: put the workpiece after the initial etching in the KOH solution, and remove the corro...

Embodiment 3

[0045] A kind of etching method, comprises the following steps:

[0046] (1) Masking the workpiece: coating a number of corrosion-resistant glue on the surface of the workpiece. The corrosion-resistant glue is a square structure with a thickness of 20 μm, and there is an uncoated corrosion-resistant glue between two adjacent corrosion-resistant glues. The gap of the glue, the width of the gap is 3 / 10 of the side length of the square corrosion-resistant glue;

[0047] (2) Put the masked workpiece into the etching machine for initial etching, the pressure of the etching solution a sprayed from the nozzle of the etching machine is 0.6psi, and the etching time is 8min, wherein the etching solution a contains FeCl 3 , water and NaCl, and FeCl 3 , the mass ratio of water and NaCl is FeCl 3 : Water: NaCl=15:35:1;

[0048] (3) Remove the film from the workpiece after the initial etching: put the workpiece after the initial etching in NaOH solution, and remove the corrosion-resistan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com