PVC (polyvinyl chloride) cutting-resisting protective gloves

A protective glove and cut-resistant technology, applied in protective clothing and other directions, can solve problems such as tactile failure, reduced cut resistance, and non-waterproof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

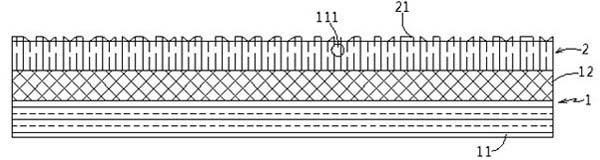

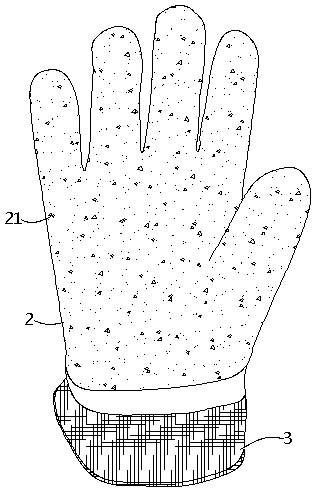

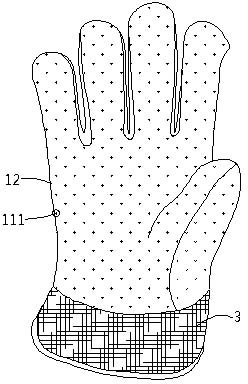

[0018] like figure 1 , figure 2 , image 3 As shown, the PVC cut-resistant protective gloves proposed by the present invention include an inner liner 1, the outer side of the inner liner 1 is coated with a PVC coating 2, and the inner liner 1 is composed of a non-woven fabric layer 11 and a knitted fabric layer 12, The knitted fabric layer 12 is located outside the non-woven fabric layer 11, and the non-woven fabric fiber 111 passes through the knitted fabric layer 12 by needle punching, so that the non-woven fabric layer 11 and the knitted fabric layer 12 are closely attached, and the PVC coating 2 is immersed in the knitted fabric layer 12. Consolidate the knitted fabric layer 12 and the non-woven fabric fibers 111 therein,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acupuncture depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com