A self-breathing electrochemical oxygen generation system

A self-breathing, oxygen-generating system technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problem of small flow of oxygen generators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

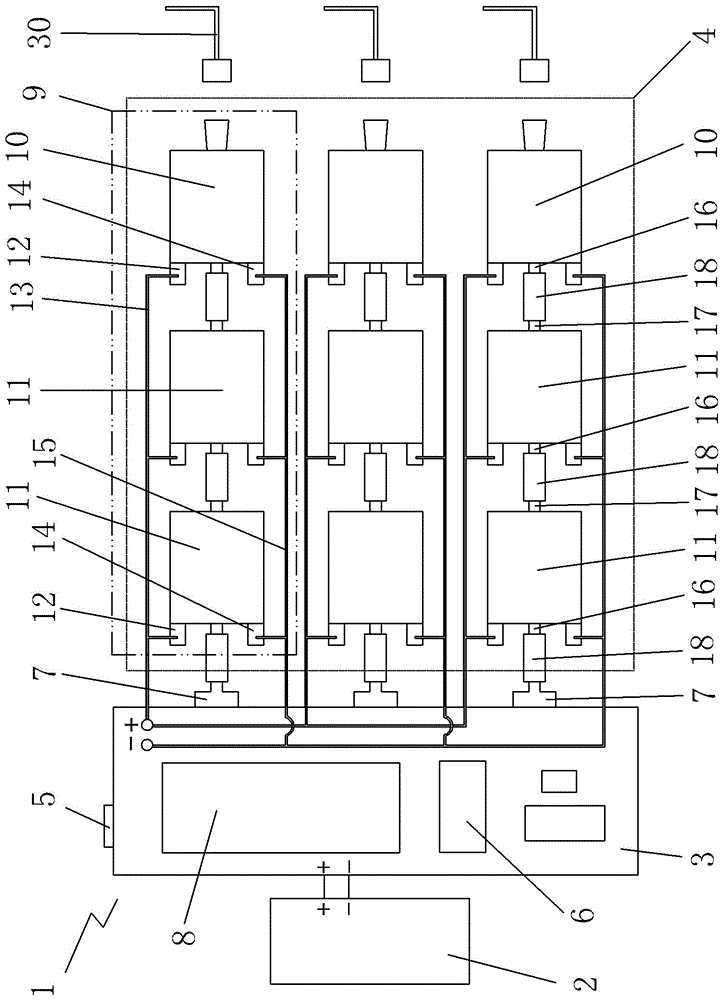

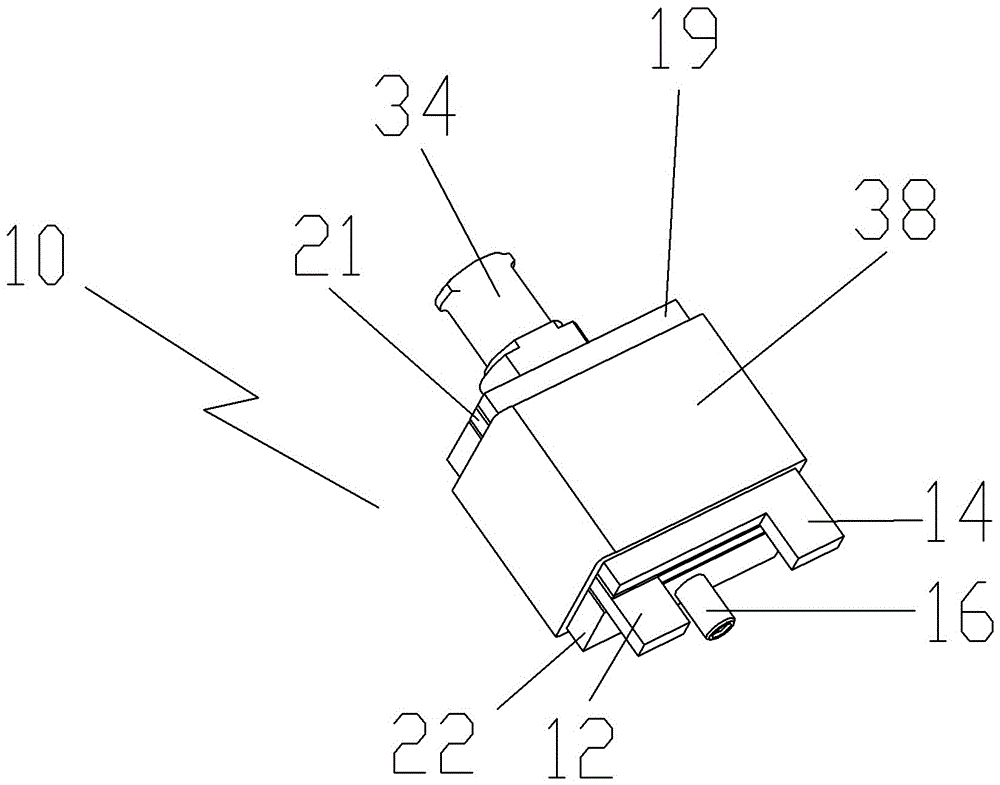

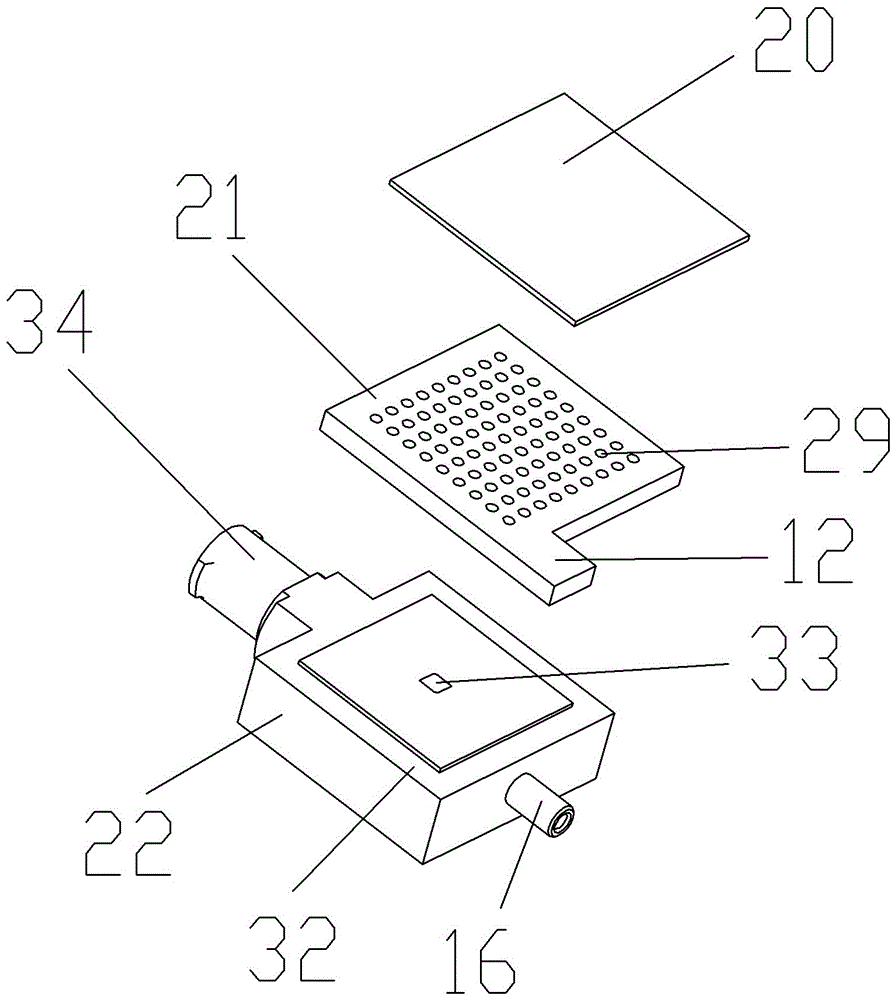

[0033] Specific embodiment one of the pure oxygen generating flow path 9: each pure oxygen generating flow path 9 includes a gas supply pure oxygen generating assembly 10, when the pure oxygen generating flow path 9 contains a pure oxygen generating assembly, the pure oxygen generating assembly The oxygen generation component is the gas supply pure oxygen generation component 10. At this time, the tail outlet pipe 16 of the gas supply pure oxygen generation component 10 is the inlet of the pure oxygen generation flow path 9, and the corresponding pressure input end of the pressure sensor 7 and the gas supply A sealing hose 18 is sheathed on the outer edge of the tail outlet pipe 16 of the pure oxygen generator assembly 10 , and the oxygen connector 34 of the pure oxygen generator assembly 10 is connected to the oxygen output pipe 30 .

specific Embodiment 2

[0034] The second specific embodiment of the pure oxygen generating flow path 9: when the pure oxygen generating flow path 9 contains two pure oxygen generating components, it includes a gas supply pure oxygen generating component 10 and an internal pure oxygen generating component 11. The tail outlet pipe 16 of the pure oxygen generation assembly 11 is the inlet of the pure oxygen generation flow path 9, the outer edge surface of the tail outlet pipe 16 of the gas supply pure oxygen generation assembly 10 and the front outlet pipe 17 of the internal pure oxygen generation assembly 11 A sealing hose 18 is set, the oxygen connector 34 of the air supply pure oxygen generating assembly 10 is connected to the oxygen output pipe 30, and the outer edge surface of the tail outlet pipe 16 of the internal pure oxygen generating assembly 11 and the pressure input end of the pressure sensor 7 is covered with a sealing soft tube. Tube 18.

specific Embodiment 3

[0035] Specific embodiment three of the pure oxygen generating flow path 9: when the pure oxygen generating flow path 9 contains at least three pure oxygen generating components, it includes a gas supply pure oxygen generating component 10, and the rest are internal pure oxygen generating components 11, At this time, the tail outlet pipe 16 of the internal pure oxygen generation assembly 11 adjacent to the pressure sensor 7 is the inlet of the pure oxygen generation flow path 9, and the oxygen connector 34 of the gas supply pure oxygen generation assembly 10 is connected to the oxygen output pipe 30. Oxygen generating components 11 are sequentially arranged on the side close to the control system 3, and the internal pure oxygen generating component 11 located at the farthest end of the control system 3 is connected to the gas supply pure oxygen generating component 10, and the tail of the gas supply pure oxygen generating component 10 is drawn out Pipe 16 and the outer edge sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com