Tungsten wire rope winding machine

A technology of tungsten wire rope and winding machine, which is used in textiles and papermaking, crystal growth, textile cables, etc., can solve the problems of not realizing self-production and self-use, collapsing pots, and the service life of steel wire ropes being difficult to meet user requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

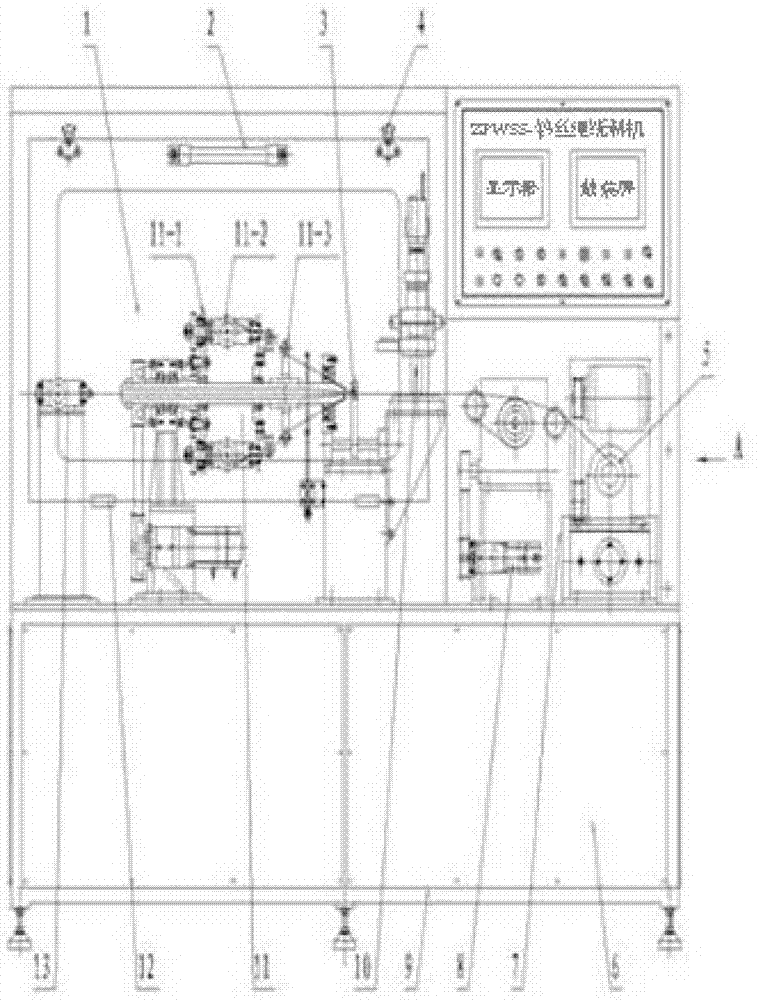

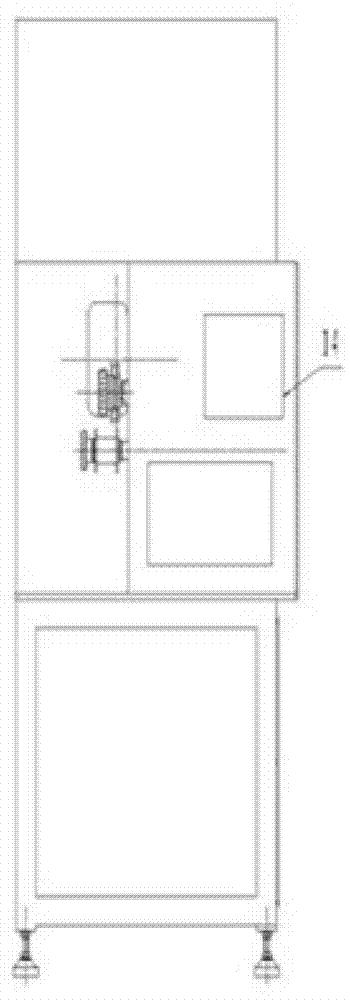

[0026] As shown in Figure 1, it is a tungsten wire rope winding machine, which has a frame 9, and one end of the frame 9 is equipped with a pay-off frame 13 for placing a raw silk reel, and a wire frame 13 is installed on one side of the pay-off frame 13 to wind the raw silk in strands. Twisting mechanism 11 made, the other side of twisting mechanism 11 is equipped with mechanical forming mechanism 3, traction mechanism 8 and automatic wire take-up and arranging mechanism 5 successively. A CCD imaging enlargement system 10 is installed between the mechanical forming mechanism 3 and the traction mechanism 8 . Frame 9 adopts fully enclosed structure, and is shaped on protective window 1, and protective window 1 is fastened by tension self-locking handle 4 and is connected by hinge 12, and the fluorescent lamp with seat is positioned in protective window 1.

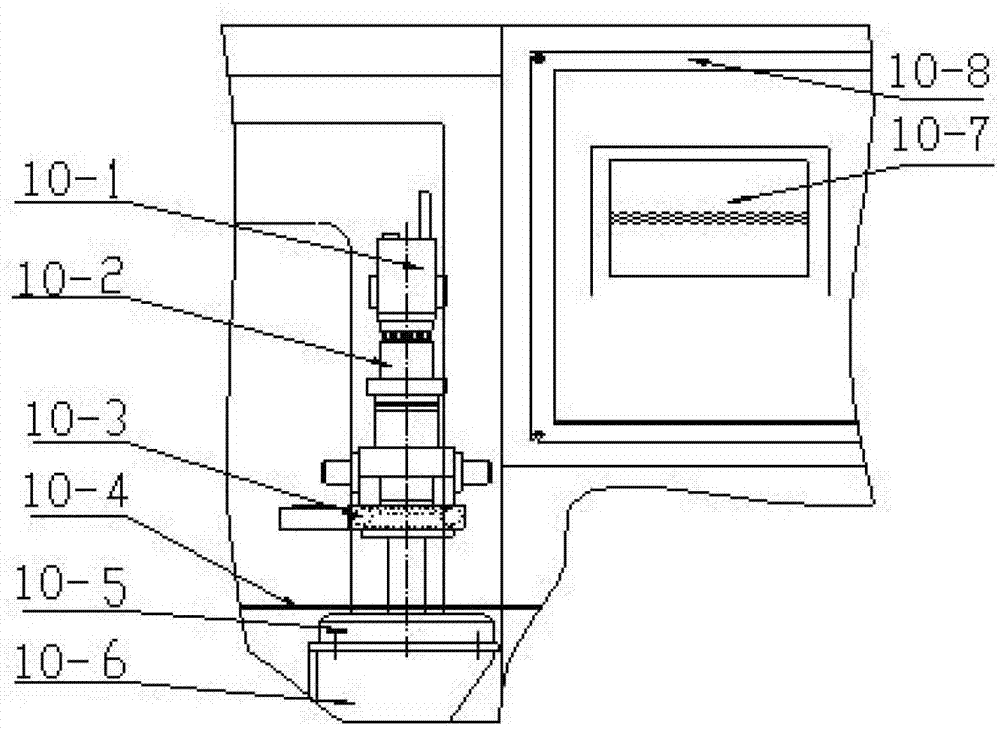

[0027] Such as figure 2 As shown, the CCD imaging and amplification system of the tungsten wire rope winding machine wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com