Bearing ball at end of tungsten wire rope and forming process

A forming process, the technology of tungsten wire rope, applied in the field of crystal growth equipment, can solve the technical problems of tungsten wire rope end bearing ball processing technology and other problems, and achieve the effect of easy mechanical extrusion and good plastic deformation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

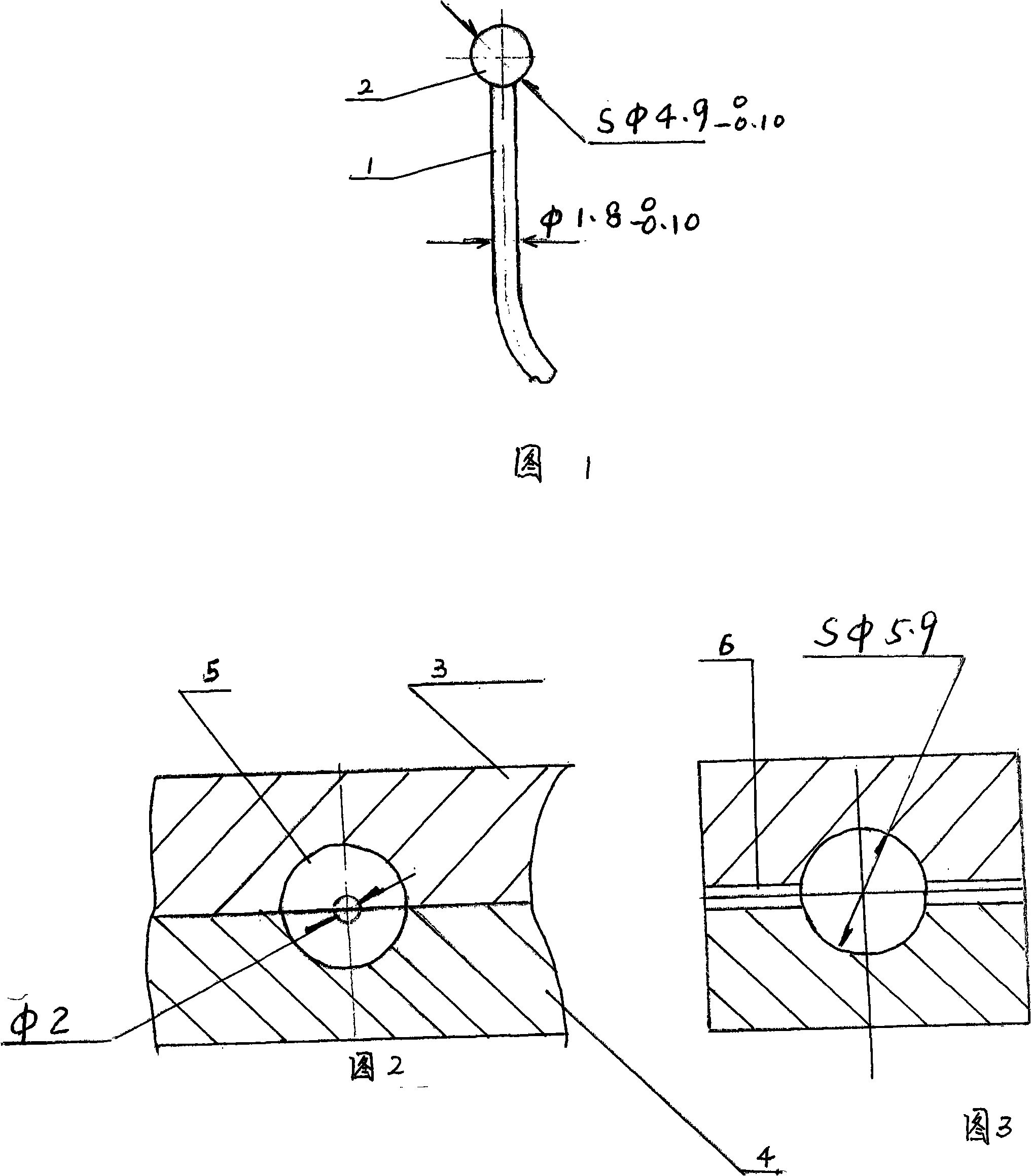

[0019] As shown in Figure 1, the end of the tungsten wire rope carries the ball, and the metal niobium or tantalum or the alloy material with niobium or tantalum as the base material is used to form a ball-like receiving carrier 2 at the end of the tungsten wire rope 1 .

[0020] As shown in Figures 2 and 3, the tungsten wire rope end bearing ball forming process is realized according to the following steps:

[0021] (1) in one comprising upper die 3 and lower die 4, and the spherical shape inner cavity 5 of the extruding die that is formed with spherical shape inner cavity 5 and tungsten wire rope channel 6 in the middle of upper die 3 and lower die 4 places suitable size Niobium or tantalum or alloy materials based on niobium or tantalum;

[0022] (2) Put the end of the tungsten wire rope 1 into the tungsten wire rope channel 6 of the extrusion die, combine the upper mold 3 and the lower mold 4 and then extrude through a press.

[0023] The extrusion die structure of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com