Titanium-coated copper bus-bar and its making method

A technology of copper busbars and busbars, applied in cable/conductor manufacturing, conductors, rods/rods/wires/strip conductors, etc. Oxidation and other problems, to achieve the effect of high current density and efficiency, good electrolytic properties, and excellent conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Copper (pure copper or copper alloy) with good electrical conductivity is prepared by coating metal with titanium (pure titanium or titanium alloy) with excellent corrosion resistance to prepare titanium-coated steel with good electrical conductivity and corrosion resistance Copper bus bars.

[0064] A copper core with a diameter of 29 mm is embedded in a titanium tube with an outer diameter of 32 mm and a thickness of 1 mm, and the outer diameter is drawn to 26 mm using a drawing device, thereby completely separating the titanium cladding and the copper core. mechanically combined. For the mechanical bonding between the copper core and the titanium tube, extrusion or rolling can also be used alone or in combination.

[0065] The mechanically bonded titanium-plated copper bus bar is heat-treated at 850° C. for 30 minutes under the protection of an inert gas to metallurgically bond the mechanically bonded titanium cladding layer and the copper core.

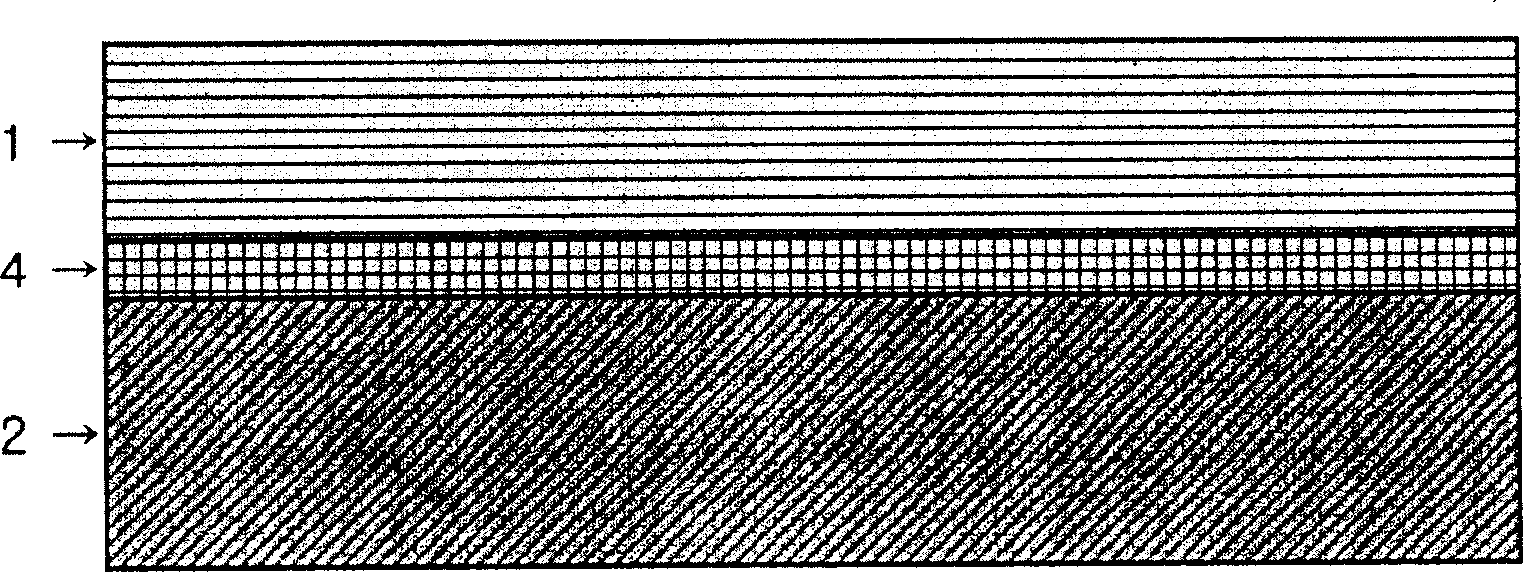

[0066] Figure 2...

Embodiment 2

[0068] A copper core with a diameter of 29 mm was embedded in a titanium tube with an outer diameter of 32 mm and a thickness of 1 mm, and the outer diameter was drawn to 26 mm using a drawing device. The drawn titanium-coated copper bus bar was heat-treated at 880° C. for 2 minutes under the protection of an inert gas to metallurgically bond the mechanically bonded titanium cladding layer to the copper core.

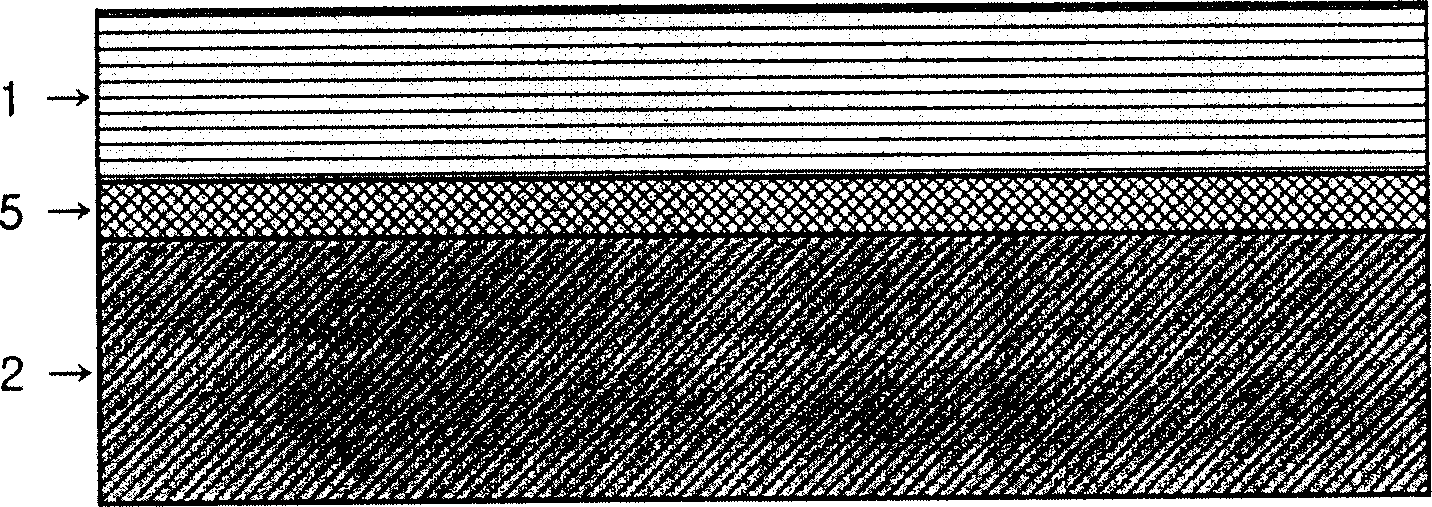

[0069] Figure 2B shows the cross-sectional microstructure of a titanium-coated copper bus bar that was heat-treated at 880° C. for 2 minutes under an inert gas protection after the first drawing. Such as Figure 2B As shown, the cross-sectional microstructure of the titanium clad layer and copper core is three layers: titanium clad layer (1), molten layer (5) and copper core (2), and shows that titanium and copper are well combined in Together.

Embodiment 3

[0071] A titanium-coated copper bus bar was prepared by first drawing and subsequent heat treatment, and the bus bar was drawn again to obtain a bus bar with an outer diameter of 24 mm, and then heat treated at 850 ° C for 30 minutes to obtain Combine well with titanium-clad copper bus bars. The resulting titanium-clad copper bus bars exhibit good metal bonding.

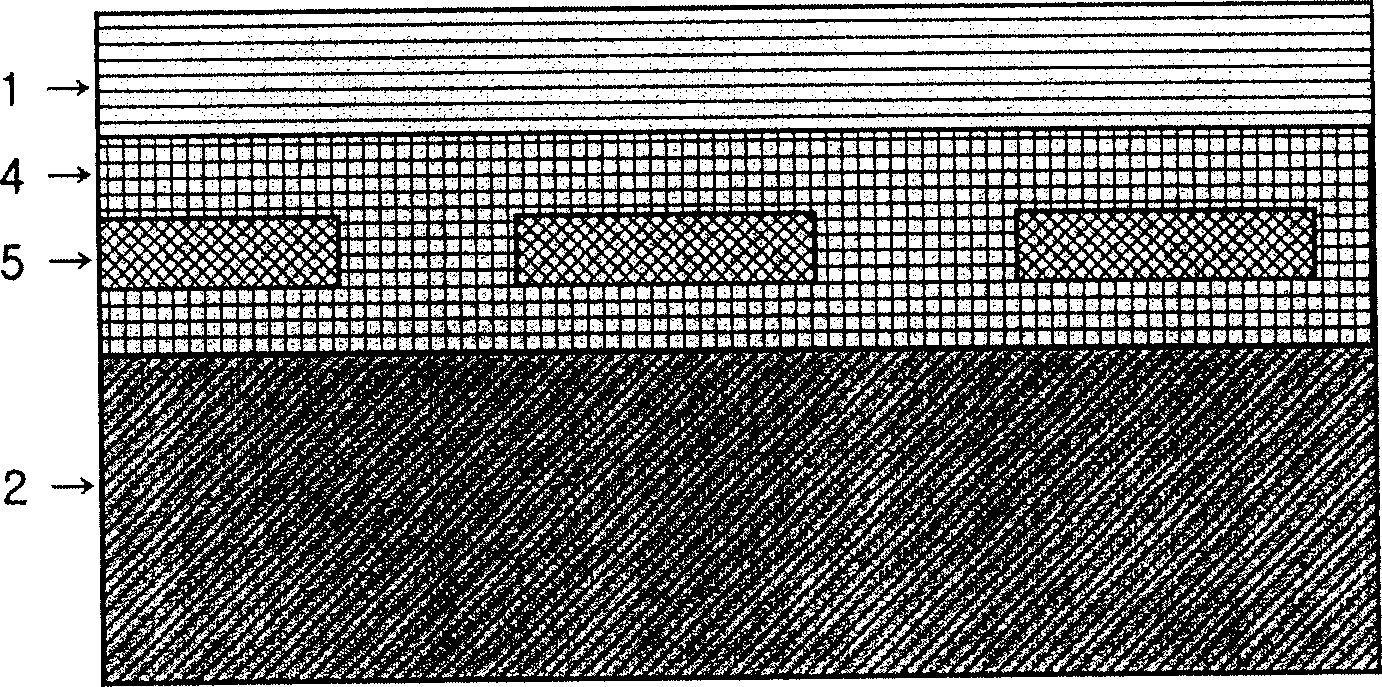

[0072] In addition, the titanium-coated copper bus bar of Example 2 having a three-layer structure of titanium clad layer (1), molten layer (5) and copper core (2) is drawn again and heat-treated at 700° C. for 10 minutes, A titanium-coated copper bus bar was produced. Figure 2C shows the cross-sectional microstructure of the as-prepared Ti-coated copper bus bars. Such as Figure 2C As shown, due to the drawing method, the molten layer formed by the brittle intermetallic compound formed by the low-temperature eutectic reaction is distributed discontinuously, but shows good metal bonding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com