An automatic anchoring and card releasing device for a cable-transmitted flame cutting device

A technology of flame cutting and cable transmission, used in wellbore/well components, earth-moving drilling and other directions to ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

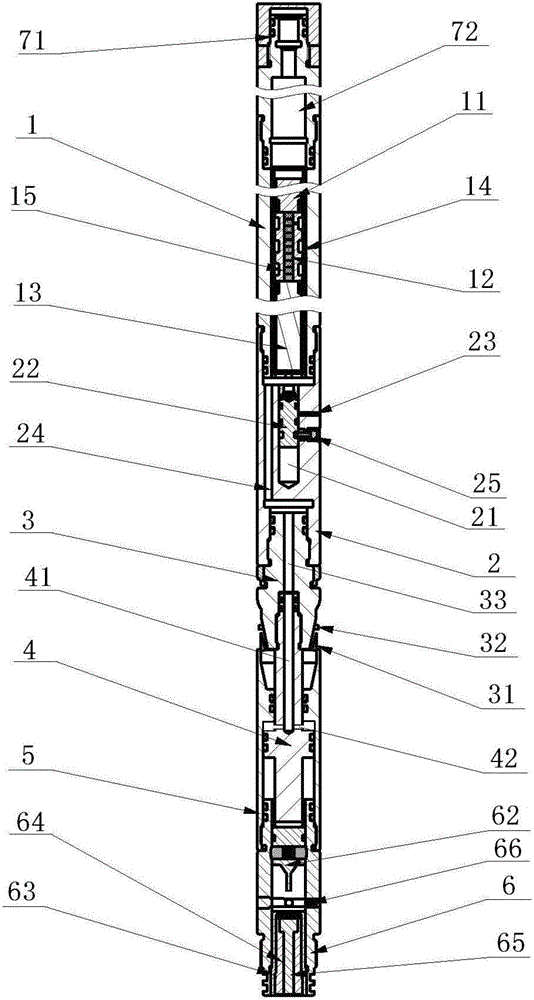

[0037] refer to Figure 1 to Figure 4 The automatic anchoring and jam-releasing device of the cable-transmitted flame cutting device provided in this embodiment is to anchor the flame cutting device: "annular combustion cutter" on the inner wall of the target pipe string during the cutting process, and the device automatically Release the jam, and lift the cutter out to cut the pipe string under the lifting force of the cable.

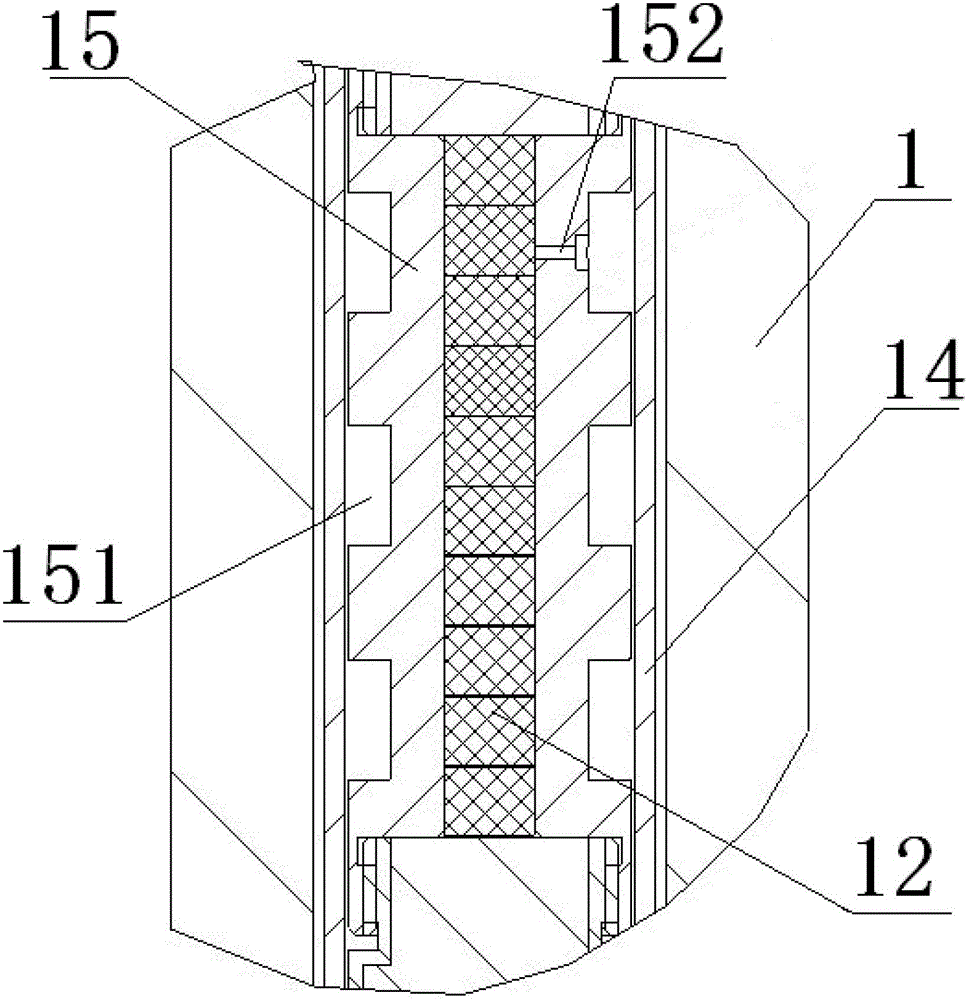

[0038]The device specifically includes a cylindrical charge combustion chamber 1, the upper end of which is connected to an ignition device, the combustion chamber 1 is equipped with a primary primary charge 11, a secondary primary charge 13 and a delay charge 12, and the delay The drug 12 is installed between the first-level main charge 11 and the second-level main charge 13, and the first-level main charge 11, the delay charge 12 and the second-level main charge 13 are loaded into the open injection shell 14 and then installed into the combustion ch...

Embodiment 2

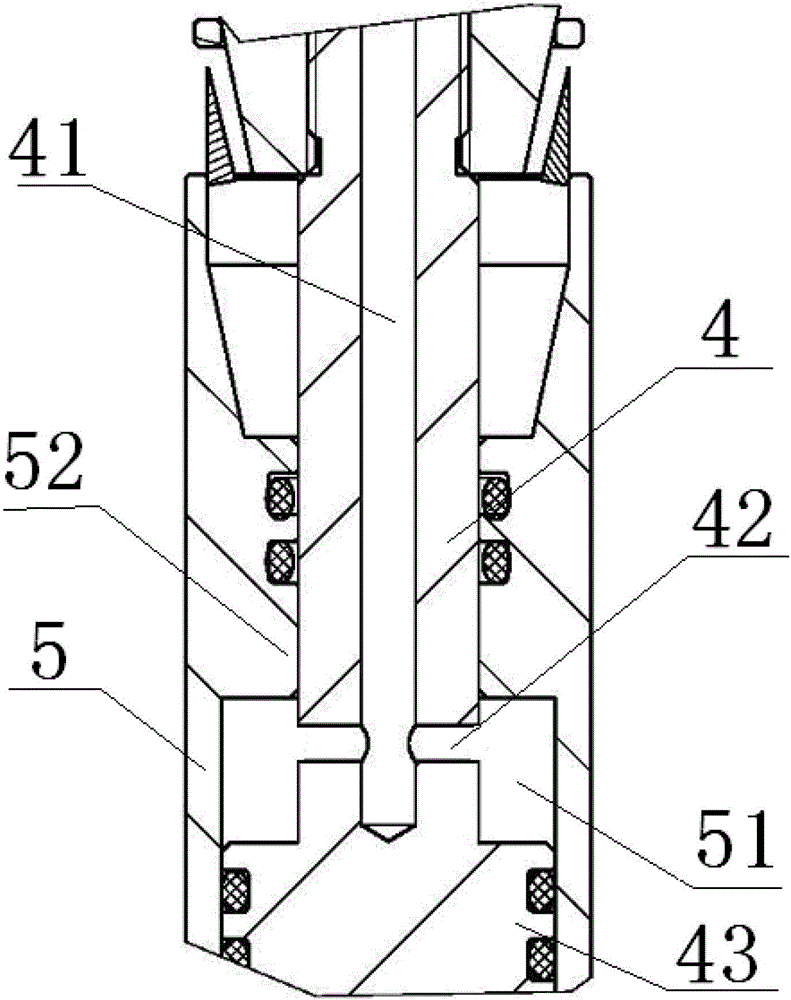

[0047] The difference between this embodiment and Embodiment 1 is that the shear ring 32 is not set on the slider joint 3, but three pins are inserted in the circumferential direction between the piston rod 4 and the support cylinder 5, and the number of pins installed is It can be determined according to the downhole pressure, generally 2 to 6.

Embodiment 3

[0049] refer to Figure 1 to Figure 4 In this embodiment, on the basis of Embodiment 1, a safety device 66 is provided between the firing pin 62 and the ignition device. The safety device 66 includes a piston hole radially opened in the lower joint 6, and one end of the piston hole is Sealed end, the other end is the open end that communicates with the outside world, a spring 663 and a piston 661 are sequentially assembled in the piston hole from the sealed end to the open end, and an axial through hole 662 is opened on the piston 661, and the axial through hole 662 deviates from the end of the firing pin 62 in the radial direction, which can prevent the firing pin 62 from hitting the propellant 65 by mistake during transportation and installation. When the device is working in the downhole, the piston 661 moves towards the sealing end of the piston hole under the pressure of the liquid in the well. Movement, and then make the axial through hole 662 and the firing pin 62 face ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com