Designing method of magneto-rheological absorber damping channel width based on characteristic requirements

A magneto-rheological shock absorber and damping channel technology, applied in vibration suppression adjustment, non-rotational vibration suppression, etc., can solve the problems of not giving accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

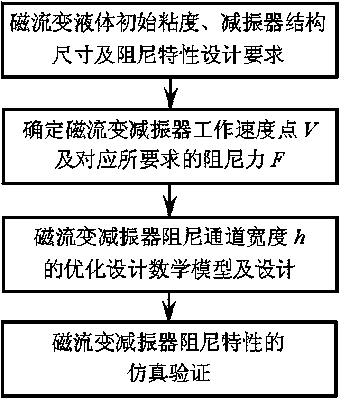

Method used

Image

Examples

Embodiment 1

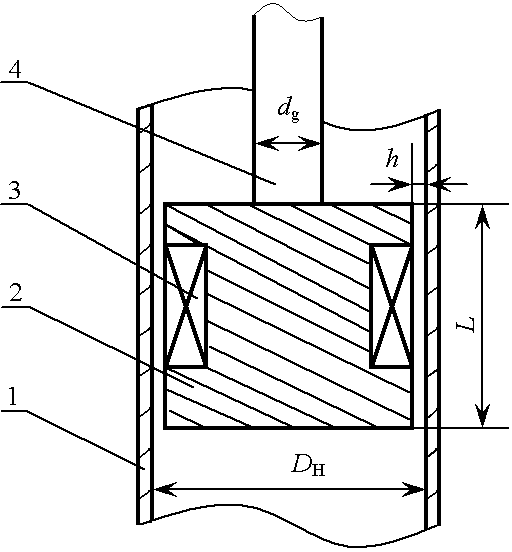

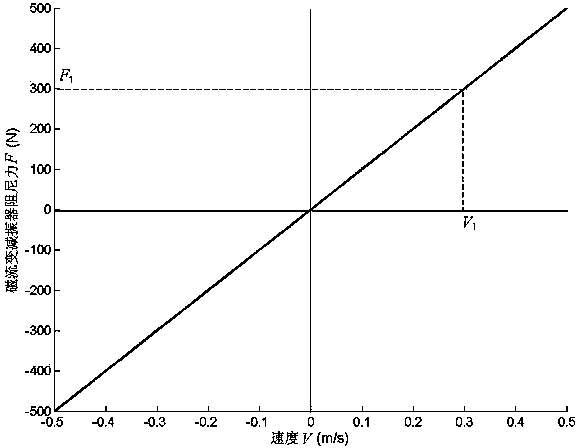

[0030] Embodiment one : Schematic diagram of the piston cylinder, piston and damping channel of an automobile magneto-rheological shock absorber, such as figure 2 As shown, the shock absorber piston cylinder 1, piston 2, electromagnetic coil 3, and piston rod 4, wherein the electromagnetic coil 3 is embedded in the middle of the piston, and the annular gap between the piston 2 and the inner wall of the piston cylinder 1 h , which is the width of the damping channel of the MR damper h . The inner diameter of the piston cylinder of the magneto-rheological shock absorber is D H =28mm, piston rod diameter d g =18mm, piston length L =40mm; the initial viscosity of the magnetorheological fluid is 0.8Pa.s when no external magnetic field is applied, and the magnetorheological damper does not apply control current I In the case, design the required damping force characteristic curve, such as image 3 As shown, the damping channel width of the magneto-rheological shock absorbe...

Embodiment 2

[0046] Embodiment two : The structural parameters of a certain automobile magneto-rheological shock absorber are the same as those in Embodiment 1, that is, the inner diameter of the piston cylinder is D H =28mm, piston rod diameter d g =18mm, piston length L =40mm. The initial viscosity of the magnetorheological fluid and the damping characteristic design requirements of the shock absorber are different from those in Embodiment 1, wherein the initial viscosity of the magnetorheological fluid is 0.7 Pa.s, and the magnetorheological shock absorber does not apply control current I In the case, design the required damping force characteristic curve, such as Figure 5 As shown, the width of the damping channel of the magneto-rheological shock absorber h design.

[0047] Using the design steps of Embodiment 1, the width of the damping channel of the magneto-rheological shock absorber h To design:

[0048] (1) Determine the working speed of the magnetorheological shock ab...

Embodiment 3

[0061] Embodiment three : The inner diameter of the piston cylinder of an automobile magneto-rheological shock absorber is D H =28mm, piston rod diameter d g =18mm, piston length L =50mm, the initial viscosity of the magnetorheological fluid is 0.9Pa.s, and the magnetorheological damper does not apply control current I In the case, design the required damping force characteristic curve, such as Figure 7 As shown, the width of the damping channel of the magneto-rheological shock absorber h design.

[0062] Using the design steps of Embodiment 1, the width of the damping channel of the magneto-rheological shock absorber h To design:

[0063] (1) Determine the working speed of the magnetorheological shock absorber V 1 and corresponding to the required damping force F 1 :

[0064] According to the magnetorheological damper when no control current is applied I In the case, design the required damping force characteristic curve, such as Figure 7 As shown, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap