Non-premix type start-up burner

A start-up burner, non-premixed technology, applied in the direction of burner, combustion method, combustion type, etc., can solve problems such as easy to be burned out, strict technical requirements, etc., to avoid damage, overcome easy damage, and avoid flame quality Falling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

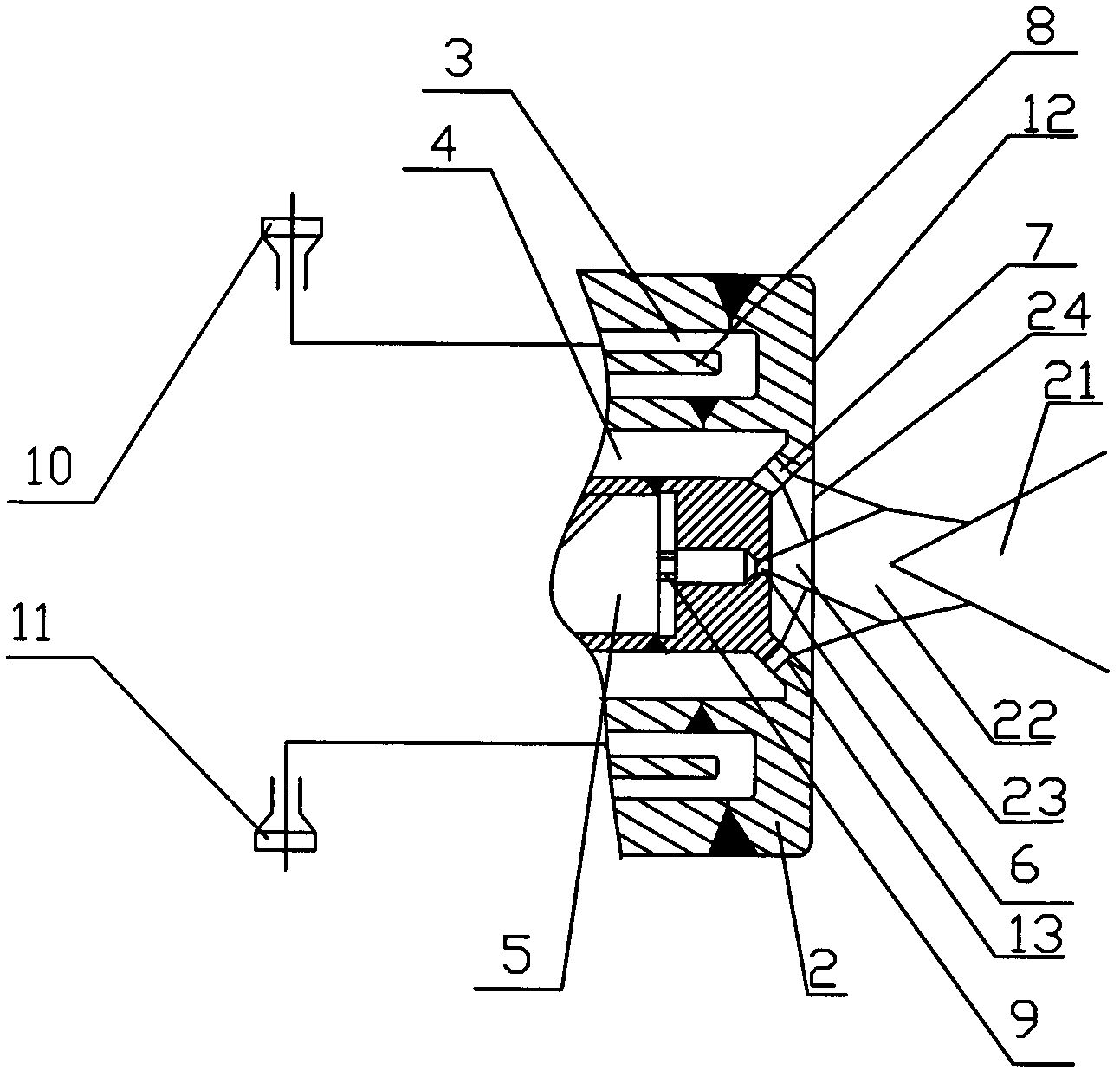

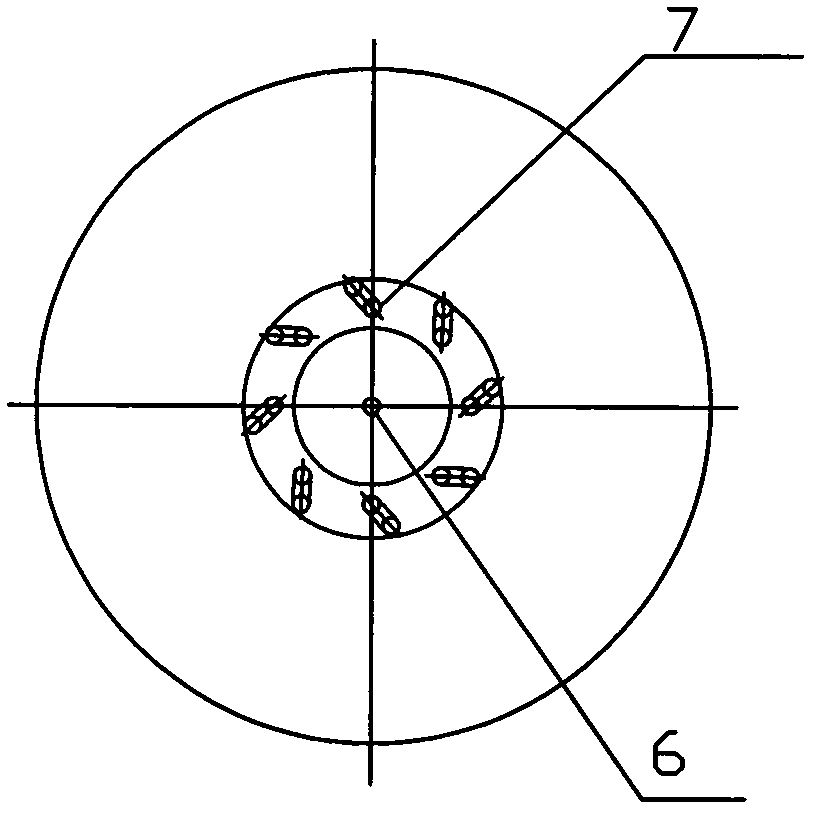

[0016] Such as figure 1 with figure 2 Shown is the non-premixed start-up burner of the present invention, the head of the burner is provided with a head injection part 2, and the head injection part includes an end panel, an oxidant channel 4, a combustion agent channel 5, a water cooling interlayer 3, and an end panel The panels are respectively welded and sealed with the oxidant channel, the combustion agent channel, and the water cooling interlayer; the end panel 12 of the head injection part is provided with a flame nozzle, and the flame nozzle includes an oxidant nozzle 7 and a combustion agent nozzle 6, and the number of the combustion agent nozzle is one; The number of nozzles is eight; the oxidizer nozzle is connected with the oxidant channel, and the burner nozzle is connected with the burner channel, and an atomizer 9 is arranged between each burner nozzle and the burner channel; the eight oxidant nozzles are evenly arranged on the combustion The range of the inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com