Desulfurized waste liquor recycling system

A technology for recycling and desulfurizing waste liquid, which is applied in the direction of gaseous effluent wastewater treatment, water/sludge/sewage treatment, water/sewage treatment, etc. It can solve the problems of increasing desulfurization cost, high price of soda ash, and low quality of circulating liquid , to achieve compact structure, easy operation, high-quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

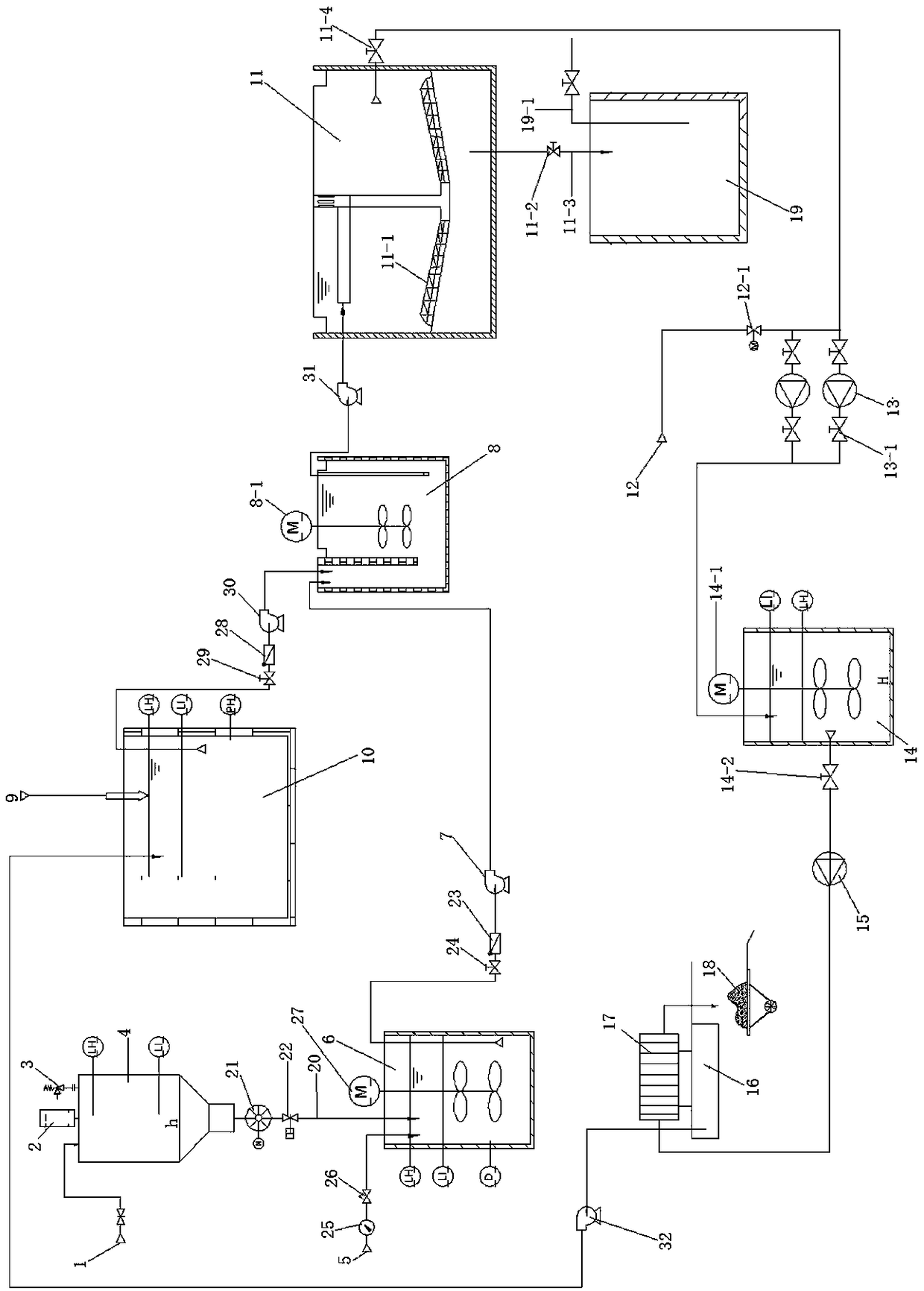

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

[0028] Refer to attached figure 1 The desulfurization waste liquid recycling system includes a hopper 4, a lime slurry tank 6, a waste liquid tank 10, a replacement tank 8, a sedimentation tank 11, a circulation tank 19, a buffer tank 14, a vacuum belt dehydrator 17 and a filter cake transport device 18 .

[0029] A feeding pipe 1 is installed on the top of the hopper 4, and quicklime is fed to the hopper through the feeding pipe 1.

[0030] A dust bag 2 is installed on the top of the hopper to facilitate the removal of lime dust in the hopper, and a safety valve 3 is installed on the top of the hopper to prevent the hopper pressure from being too high. Feeding pipe 20 is equipped with at the bottom of hopper 4, and metering feeder 21, feeding control electromagnetic valve 22 are housed on feeding pipe 20, and feeding pipe 20 is communicated in lime slurry pool 6 top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com