Weighing cell operating on the principle of electromagnetic force compensation with optoelectronic position sensor

A weighing cell, compensation principle technology, applied in the field of balances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

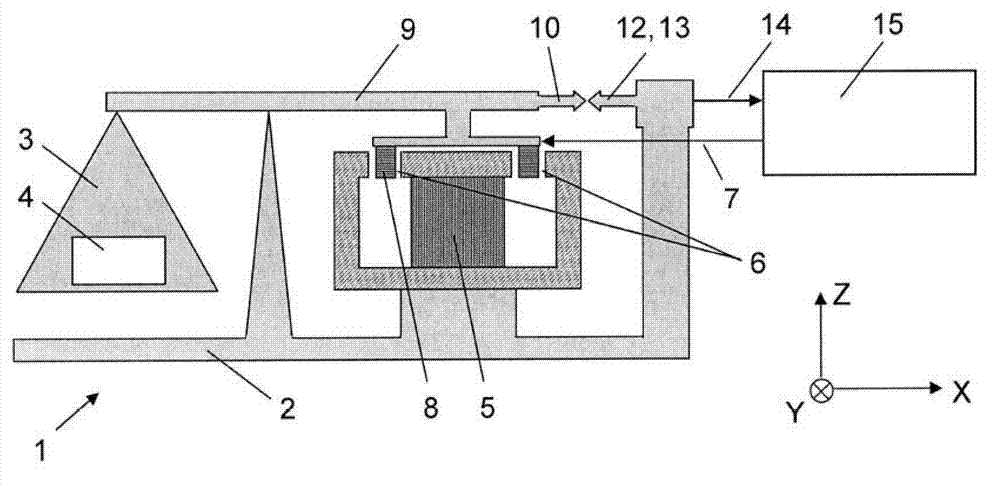

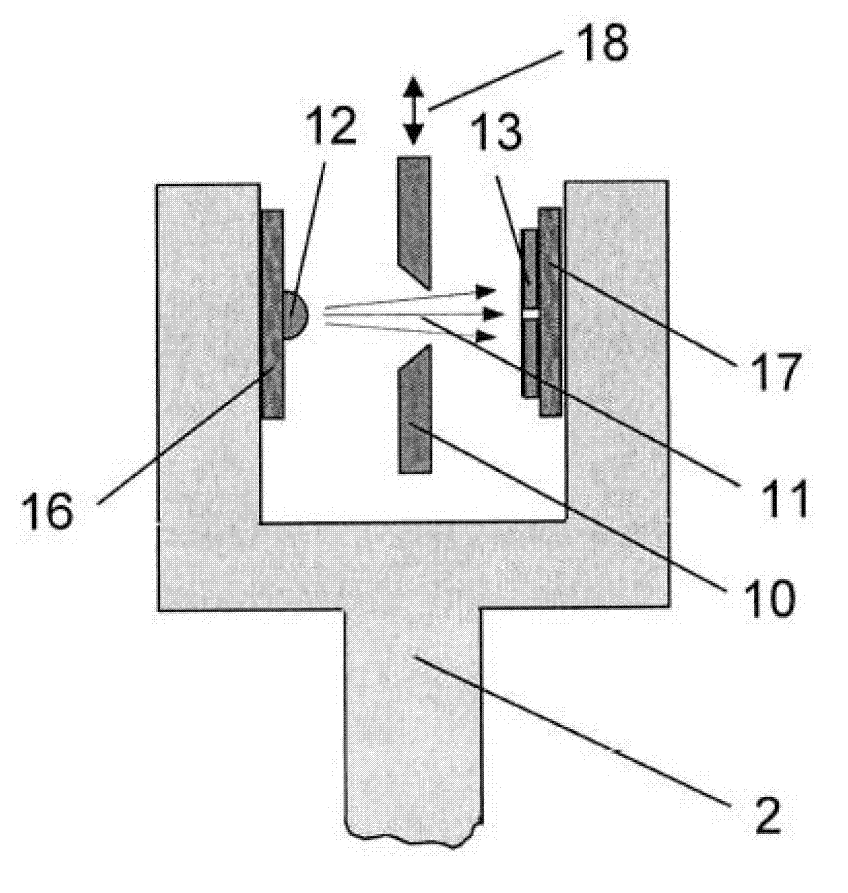

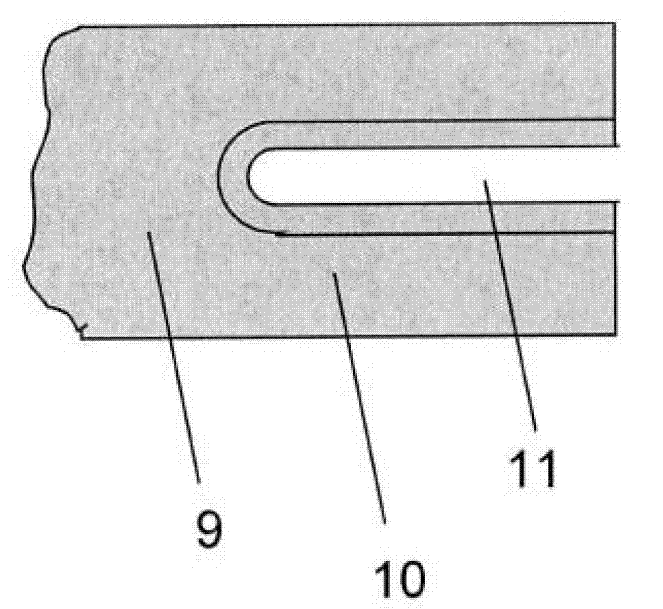

[0041] figure 1 It schematically shows a weighing unit with electromagnetic force compensation and photoelectric position sensor. Add a Cartesian coordinate system X, Y, Z as a reference, where X axis and Z axis are located figure 1 In the drawing plane, and the Y axis points to the space behind the drawing plane. The identifiable elements of the weighing unit 1 in the figure include a fixed base part 2; a load receiver 3, which is constrained by a balance beam 9 to be guided and movable relative to the base part 2; firmly installed on the base part 2 The cup-shaped permanent magnet system 5 (shown in cross-sectional view) of the permanent magnet system; the air gap 6 of the permanent magnet system, the coil 8 conducting the compensation current 7 is movably suspended in the air gap; and the load receiver 3 and the coil 8 The force-transmitting mechanical connection between the two is in the form of a balance beam 9 here. Photoelectric position sensor ( figure 1 Is displayed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com