Electro-hydraulic loading device for reducer test

A technology of loading device and reducer, which is applied in the test of machine gear/transmission mechanism, fluid pressure actuating device, servo motor, etc., can solve the problem of inability to obtain technical parameters of high-efficiency reducer, poor stability of loading performance, and large size of magnetic powder brake and other problems, to achieve the effect of stable loading performance, stable performance and large loading torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

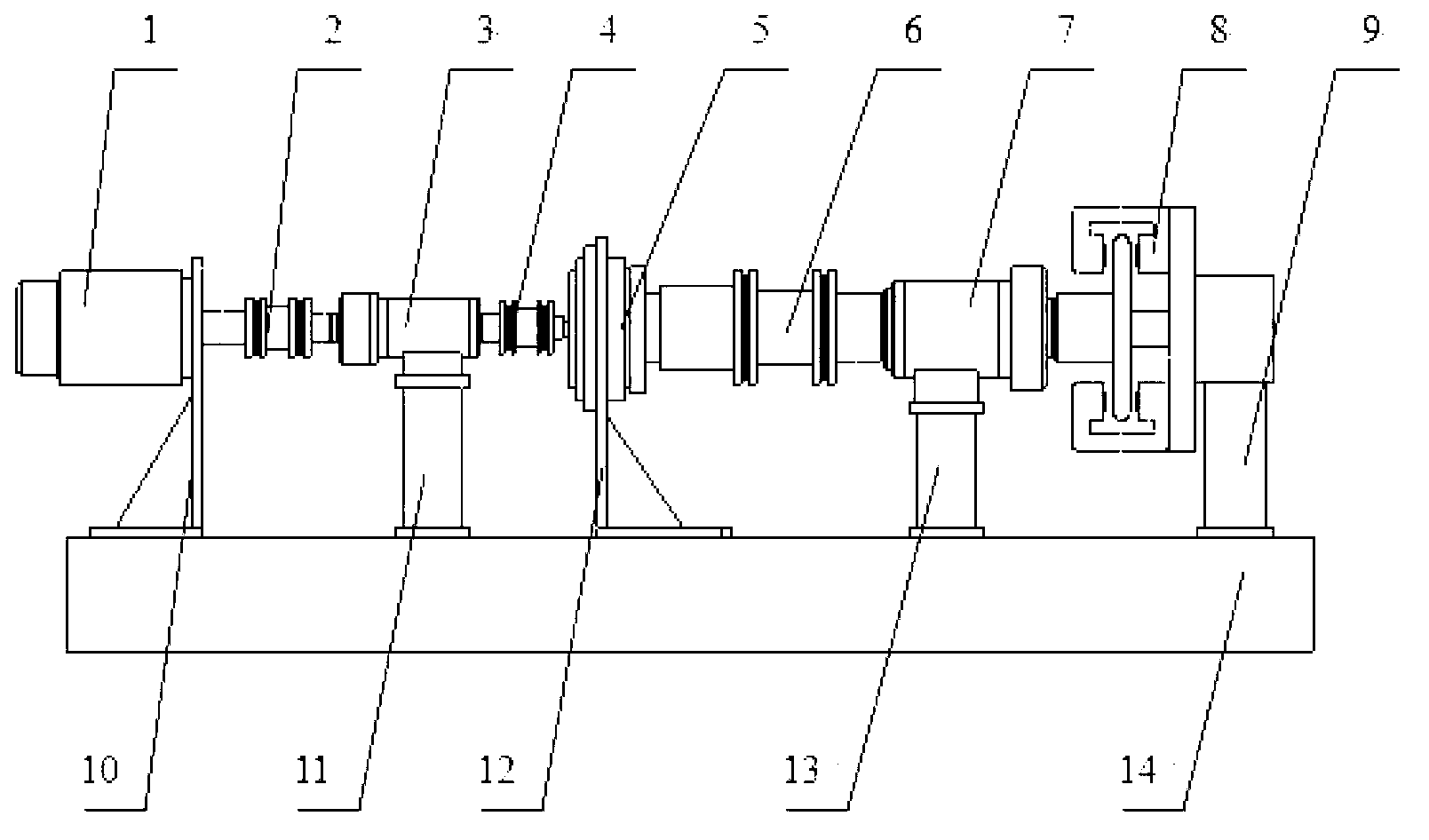

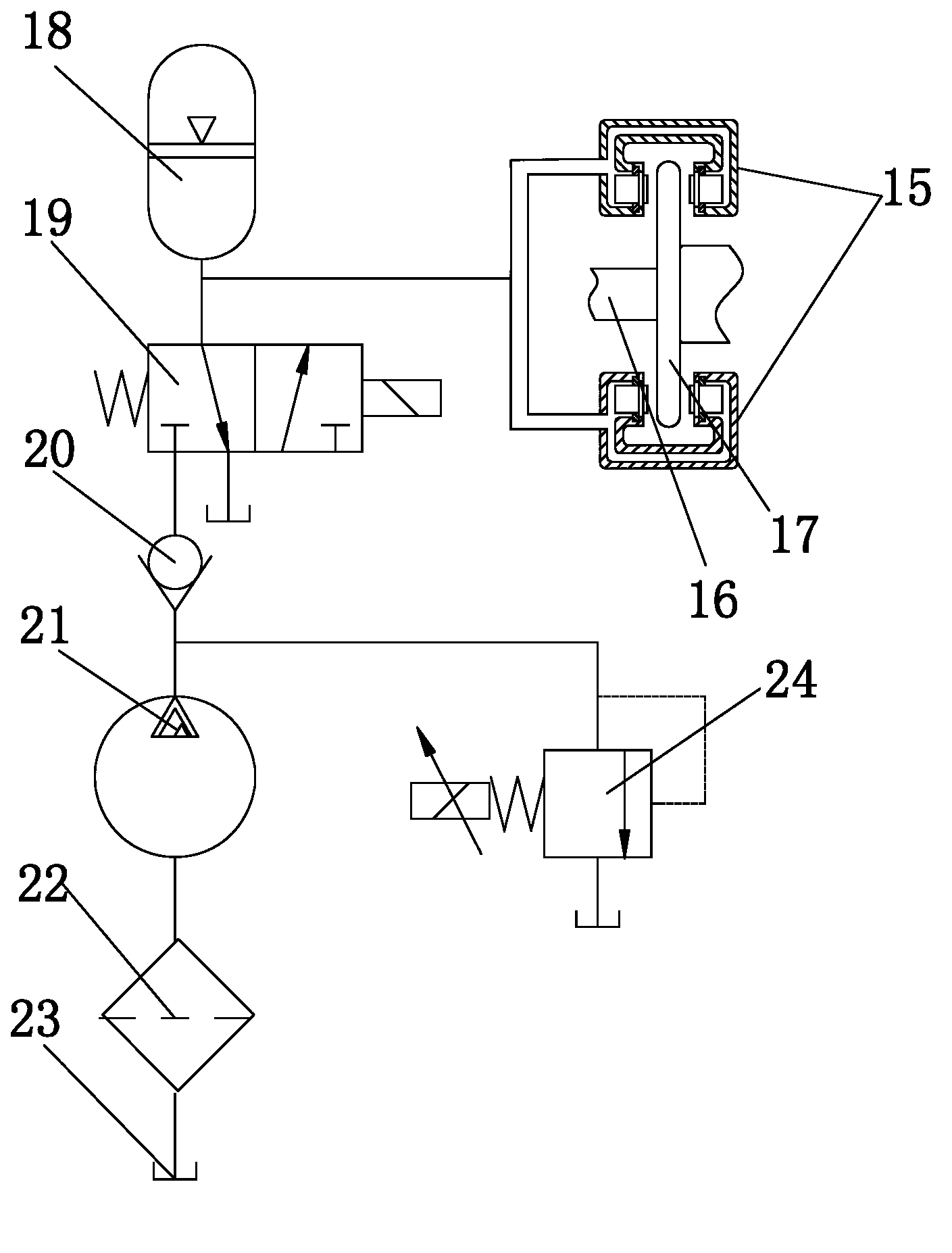

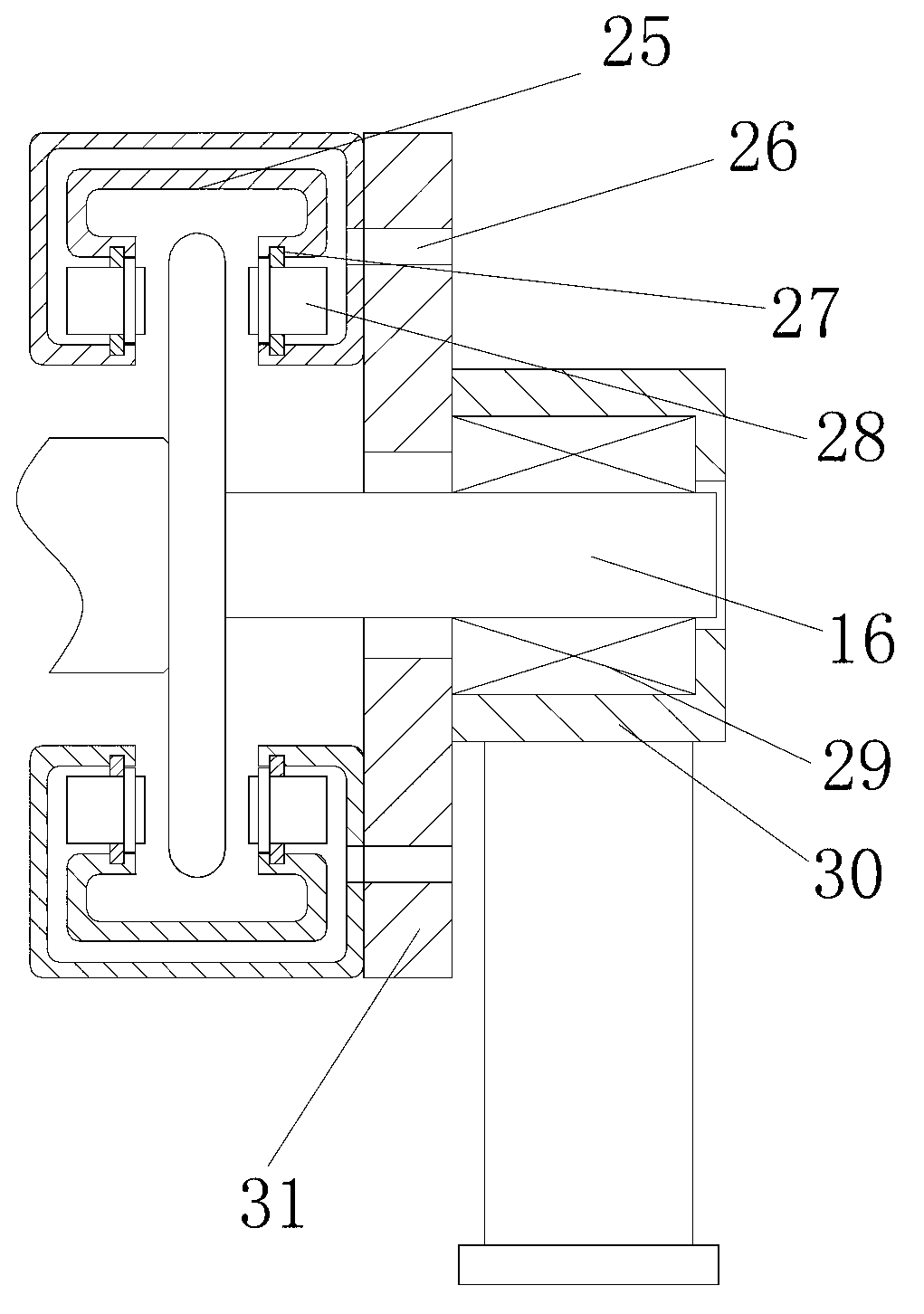

[0018] Example. An electro-hydraulic loading device for speed reducer testing, constituted as Figure 1-4 As shown, the base 14 is included, and the base 14 is provided with a drive motor 1, a first coupling 2, a torque angular displacement sensor 3 at the input end of the reducer, a second coupling 4, and a drive motor 1, which is kept horizontally coaxial and connected in sequence. Reducer 5, third coupling 6, torque angular displacement sensor 7 at the output end of the reducer, and electro-hydraulic loading mechanism 8. The electro-hydraulic loading mechanism 8 includes a loading cylinder 15, and a rotating shaft with a brake disc 17 is arranged in the loading cylinder 15 16. The loading cylinder 15 is sequentially connected with an accumulator 18 , a switching valve 19 , a check valve 20 , a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com