Computing method for circumferential stress of equivalent structure circular sandwich valve plate of absorber

A technology of circumferential stress and superimposed valves, which is applied in the field of hydraulic shock absorbers, can solve problems such as the lack of analytical calculation formulas or calculation methods, and the difficulty in meeting the design and production requirements of shock absorber superimposed valve plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

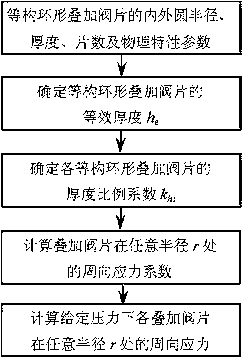

Method used

Image

Examples

Embodiment 1

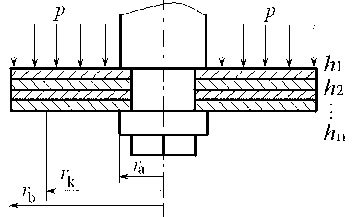

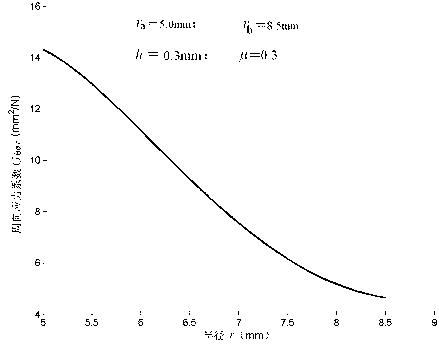

[0038] Embodiment one: The radius of the inner circle of a shock absorber with an isostructured annular superimposed valve plate ra =5.0mm, outer circle radius r b =8.5mm, valve port radius =8.0mm modulus of elasticity E =200GPa, Poisson's ratio mu =0.3, the thickness and number of superimposed valve plates are respectively h 1 =0.1mm, n 1 =3; h 2 =0.15mm, n 2 =2; h 3 =0.2mm, n 3 =1, uniform pressure p =3.0MPa.

[0039] (1) Determine the equivalent thickness of the isomorphic annular superimposed valve plate h e :

[0040] According to the thickness and the number of circular superimposed valve plates of a certain shock absorber h 1 =0.1mm, n 1 =3; h 2 =0.15mm, n 2 =2; h 3 =0.2mm, n 3 =1, the equivalent thickness of the isomorphic annular superimposed valve plate h e for:

[0041] =0.260855mm;

[0042] (2) Determine the thickness proportional coefficient of the isomorphic annular superimposed valve plate k hi

[0043] Accordin...

Embodiment 2

[0063] Embodiment two: The structural parameters and material characteristic parameters of a shock absorber isomorphic annular superimposed valve plate are exactly the same as those in Example 1, and the thickness and number of superimposed valve plates are respectively h 1 =0.1mm, n 1 =1; h 2 =0.15mm, n 2 =1; h 3 =0.2mm, n 3 =1, pressure p =3.0MPa.

[0064] (1) According to the thickness and number of stacked valve plates h 1 =0.1mm, n 1 =1; h 2 =0.15mm, n 2 =1; h 3 =0.2mm, n 3=1, to determine the equivalent thickness of the shock absorber isomorphic annular superimposed valve plate h e for:

[0065] = 0.231303mm;

[0066] (2) According to the thickness of the isomorphic annular superimposed valve plate h 1 =0.1mm, h 2 =0.15mm, h 3 =0.2mm, and the equivalent thickness in step (1) h e =0.231303mm, determine the thickness proportional coefficients of each superimposed valve plate as:

[0067] k h 1 = 0.43233, = 0.6485, = 0....

Embodiment 3

[0075] Embodiment three: The material characteristic parameters and inner circle radius of a shock absorber isomorphic annular superimposed valve plate are the same as those in Example 1, and the outer circle radius =8.75mm, the thickness and number of superimposed valve plates are respectively h 1 =0.15mm, n 1 =1; h 2 =0.2mm, n 2 =3, the pressure is evenly distributed p =3.0MPa.

[0076] Adopt exactly the same steps as Example 1, namely:

[0077] (1) According to the thickness and number of stacked valve plates h 1 =0.15mm, n 1 =1; h 2 =0.20mm, n 2 =3, to determine the equivalent thickness of the isomorphic annular superimposed valve plate h e for:

[0078] = 0.30138mm;

[0079] (2) According to the thickness of the isomorphic annular superimposed valve plate h 1 =0.15mm, h 2 =0.2mm, and the equivalent thickness in step (1) h e =0.30138mm, determine the thickness proportional coefficients of each superimposed valve plate as:

[0080] k h 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner radius | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com