Lithium battery rolling automatic centering and deviation correcting device

A deviation correction device, lithium battery technology, applied in electrode manufacturing and other directions, can solve the problems of pole piece offset, high labor intensity, and reduce production efficiency, and achieve the effect of ensuring consistent stacking, reducing labor intensity, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

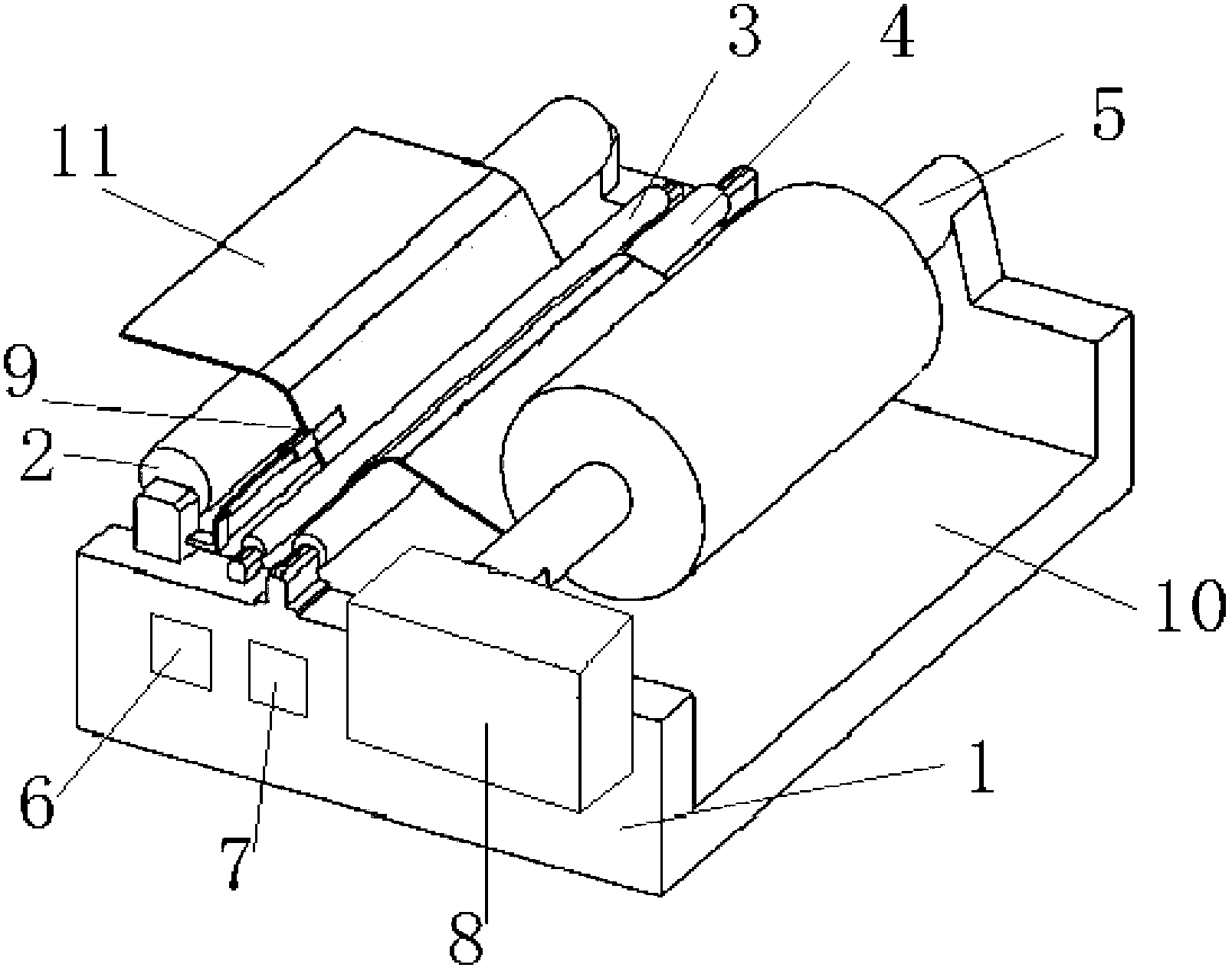

[0019] refer to figure 1 A lithium battery rolling automatic edge correction device shown includes a base 1, and a first pressing roller 2, a second pressing roller 3, a third pressing roller 4, and a receiving roller 5 arranged on the base 1 , A / D conversion module 6, programmable controller 7 and stepper motor 8, the first pressure roller 2, the second pressure roller 3, the third pressure roller 4 and the receiving roller 5 are arranged in sequence from left to right, And it is movably connected with the base 1, the first pressure roller 2 is provided with a photoelectric sensor 9 connected to the A / D conversion module 6, and the photoelectric sensor 9 is connected with the stepping motor 8 through the programmable controller 7, A ball screw transmission mechanism (not shown) is provided between the stepper motor 8 and the receiving roller 5 .

[0020] Wherein, a groove 10 is provided in the middle of the base 1 .

[0021] The first pressing roller 2, the second pressing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com