Triple-core-wire automatic assembling equipment

An assembly equipment and three-core wire technology, which is applied to the assembly/disassembly of contacts, circuit/collector components, electrical components, etc., can solve problems such as low work efficiency, time-consuming and labor-intensive, and no automation equipment to achieve efficiency improvement , reduce production costs and enhance market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]In conjunction with the accompanying drawings, the present invention is described in detail, but the scope of protection of the present invention is not limited to the following embodiments, that is, all simple equivalent changes and modifications made with the patent scope of the present invention and the content of the specification are still patents of the present invention. covered.

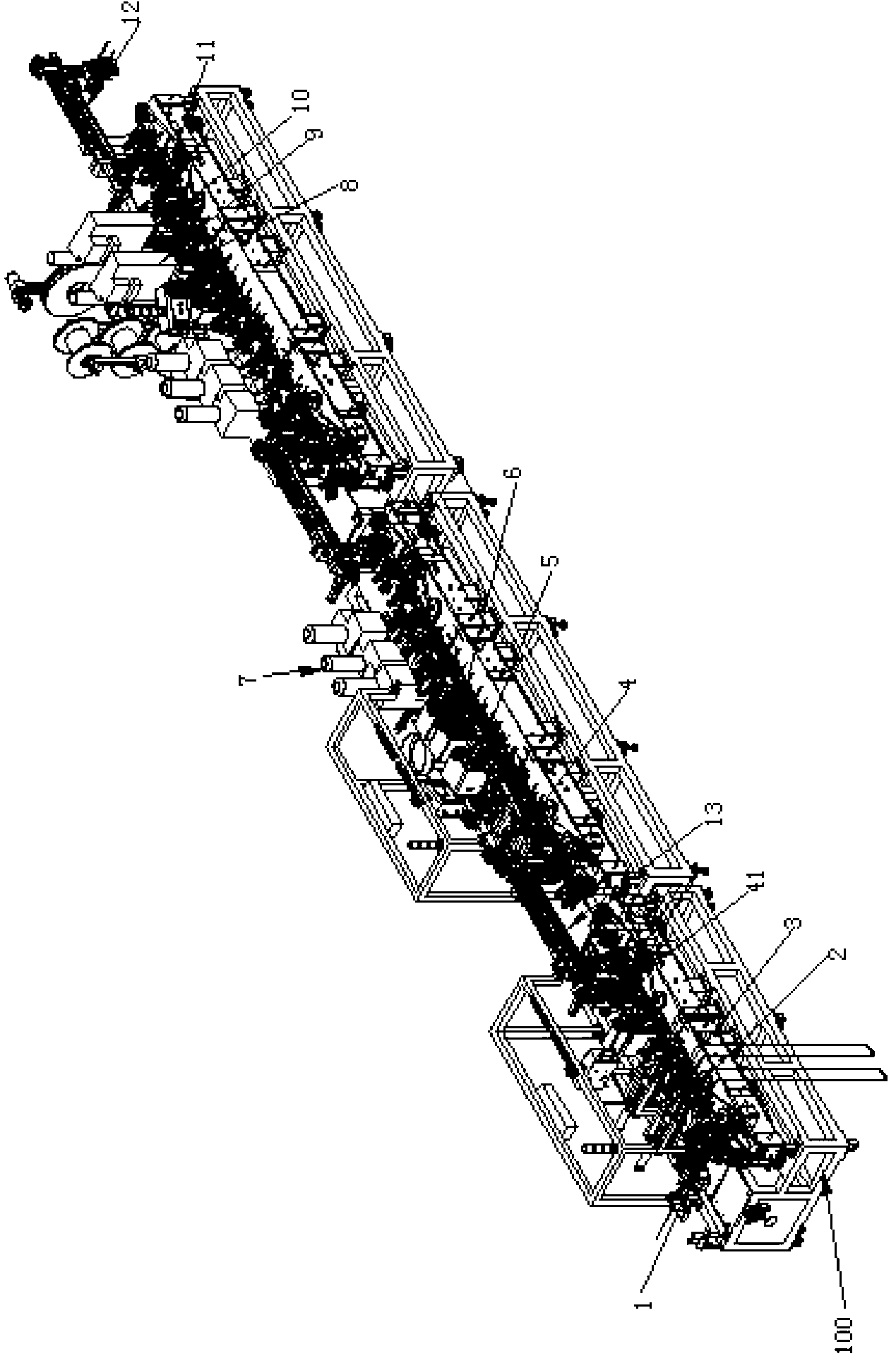

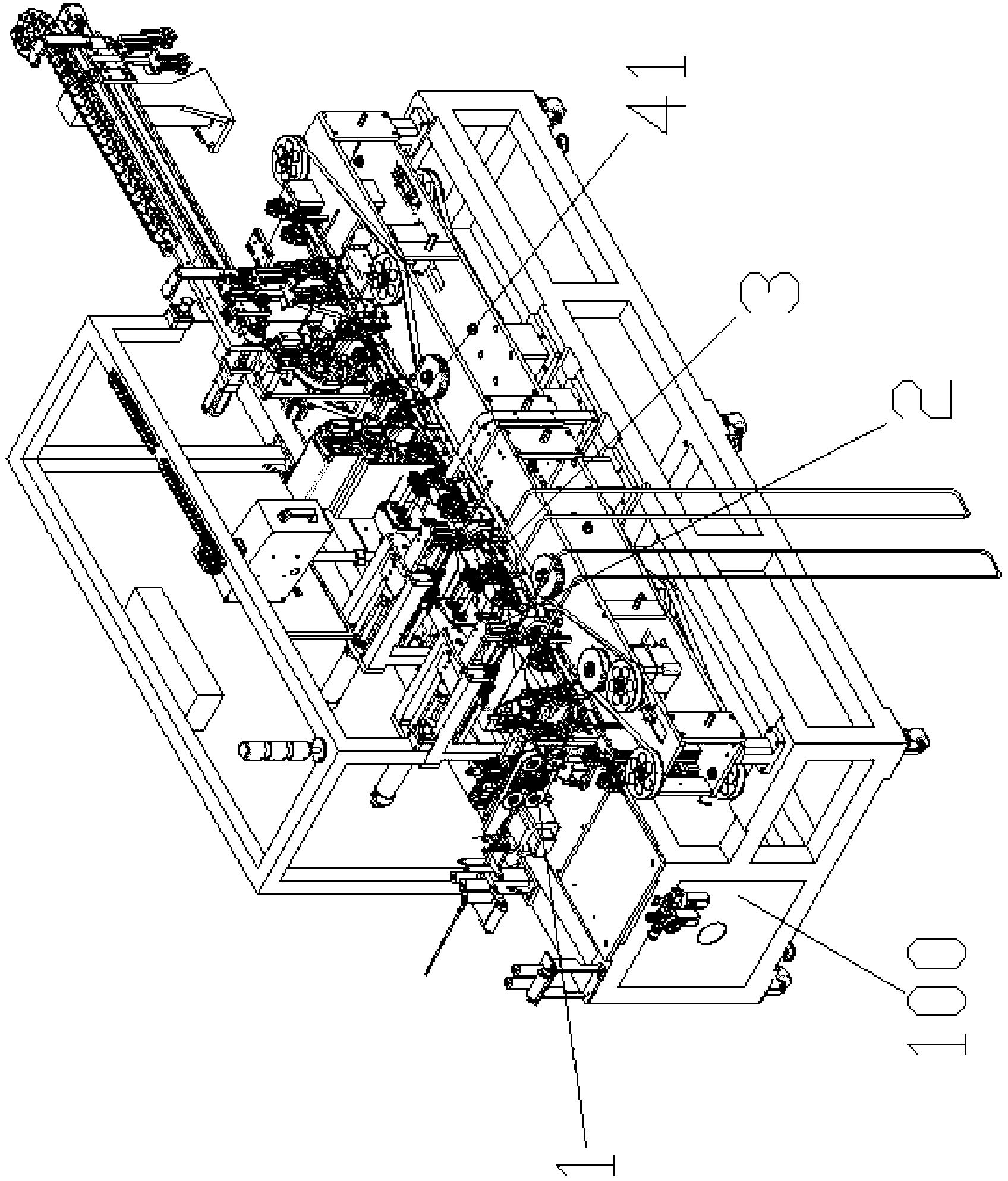

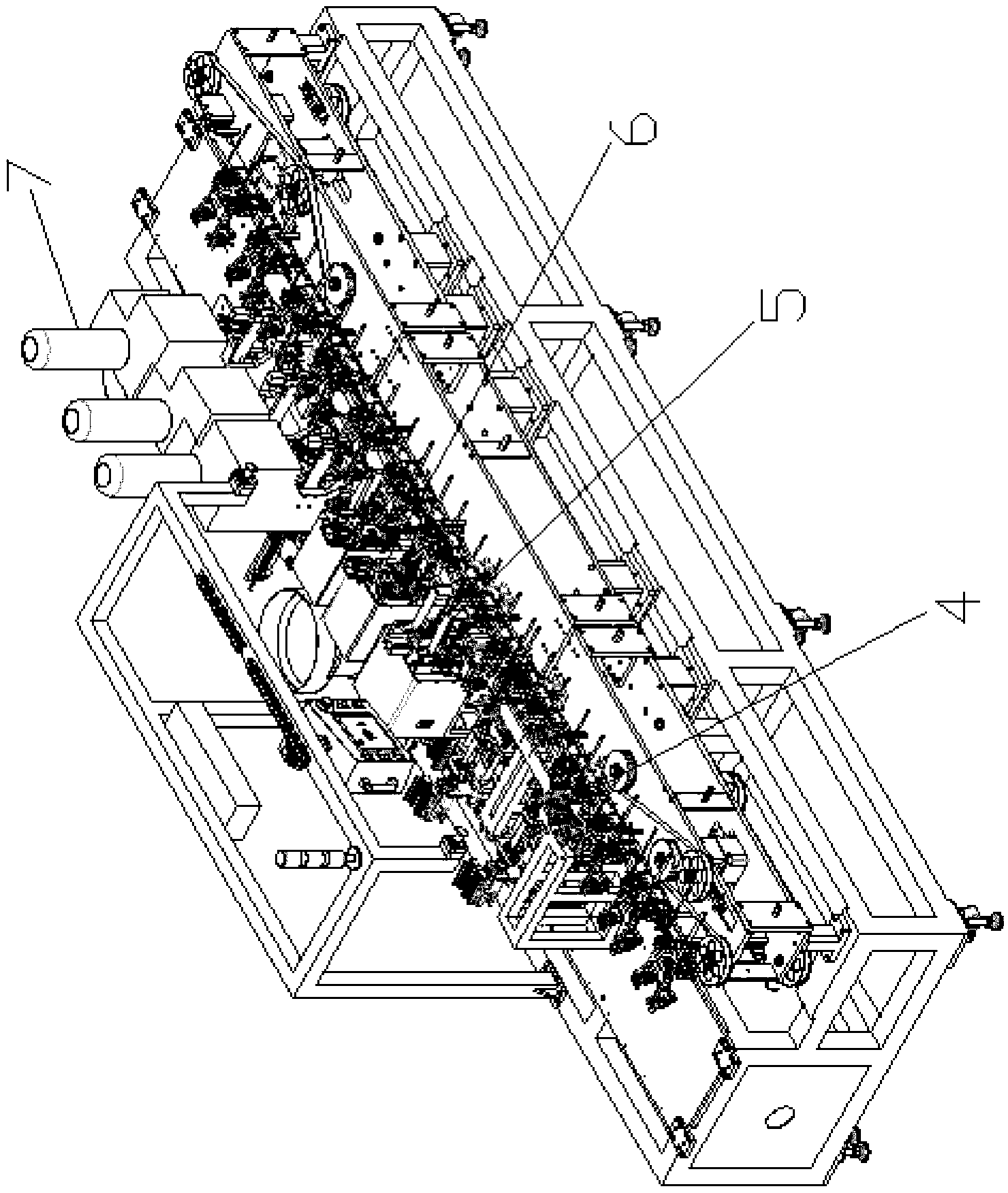

[0034] Such as Figure 1-9 As shown, a three-core wire automatic assembly equipment includes a workbench 100, on which a wire feeding station 1, a sheath stripping station 2, a branching station 4, and a wire length adjustment station 5 are sequentially arranged. , Stripping inner quilt station 6, terminal crimping station 7, PVC pipe assembly station 8, ultrasonic welding station 9, flag-shaped sheath assembly station 10, flag-shaped sheath trimming station 11, finished product The porter station 12 and the transmission device 13 that sequentially transports the cables to each station...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com