MEMS (Micro-electromechanical Systems) microphone

A microphone and circuit board technology, applied in electrostatic transducer microphones and other directions, can solve problems such as shortening the service life of MEMS microphones, MEMS microphones not working properly, and damaging MEMS chips, improving acoustic performance, reducing the probability of being damaged, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

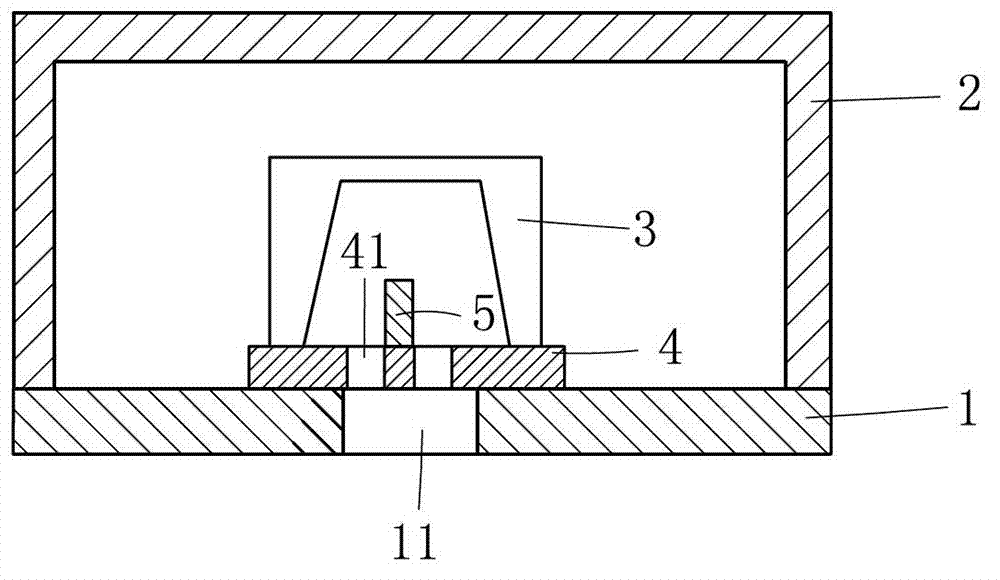

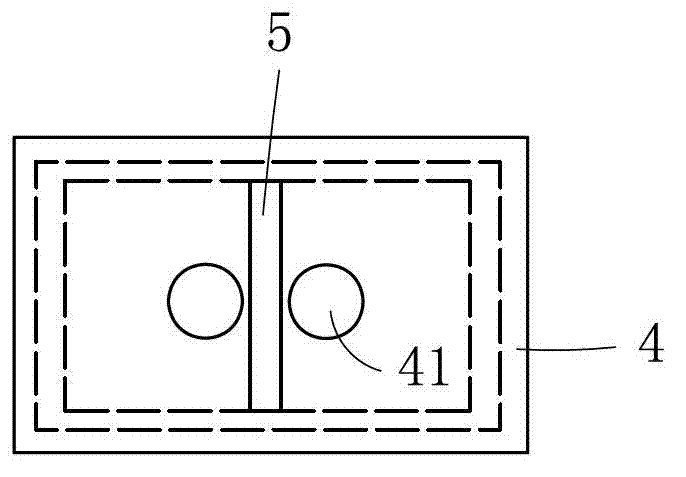

[0025] Such as figure 1 and figure 2 Commonly shown, a kind of MEMS microphone comprises the housing 2 that is made by metal material or circuit board material, and housing 2 is the cylindrical structure that one end is open and one end is closed, and the open end of housing 2 is combined with circuit board 1, and circuit board 1 and The combined side of the shell 2 is the inner side of the circuit board 1 , and the center of the circuit board 1 is provided with a first sound hole 11 , and the diameter of the first sound hole 11 is 0.25±0.05 mm. The inner side of the circuit board 1 corresponding to the first sound hole 11 is bonded with a support member 4. The support member 4 is a flat plate structure. Two second sound holes 41 are arranged on the support member 4. The aperture of the second sound hole 41 is 0.01- 0.1 mm, the diameter of the second acoustic hole 41 in this embodiment is preferably 0.03-0.05 mm, the two second acoustic holes 41 are located in the orthograp...

Embodiment 2

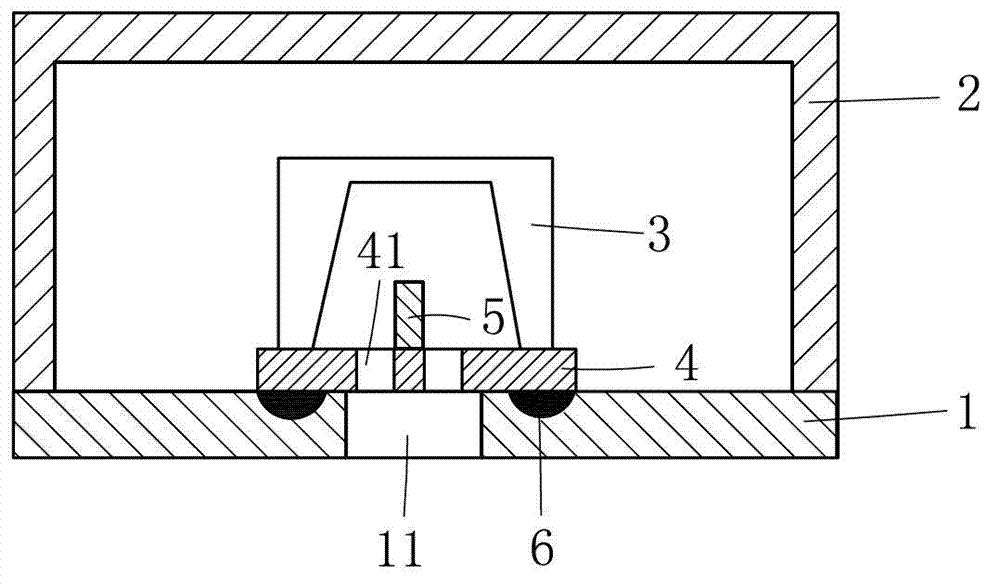

[0031] Such as image 3 As shown, this embodiment is basically the same as Embodiment 1, the difference is:

[0032]A glue overflow groove 6 is provided on the circuit board 1 at the position where the support member 4 is attached to the circuit board 1 . When the support member 4 is pasted and combined with the circuit board, the excess glue can easily block the sound hole, and the excess glue groove 6 can collect the excess glue, which effectively solves the problem that the sound hole is easily blocked, and improves the performance of the MEMS microphone. Finished product pass rate.

[0033] The overflow groove 6 corresponds to the edge of the support 4, and the edge of the support 4 is far away from the first sound hole 11 and the two second sound holes 41, further preventing the sound holes from being blocked.

Embodiment 3

[0035] Such as Figure 4 As shown, this embodiment is basically the same as Embodiment 1, the difference is:

[0036] A groove is provided on the circuit board 1 corresponding to the position of the support member 4 , the support member 4 is pasted in the groove, and a part of the support member 4 protrudes from the plane of the circuit board 1 .

[0037] Compared with the first embodiment, this embodiment makes full use of the thickness of the circuit board 1 to reduce the space occupied by the support member 4 in the z-axis direction, which can make the MEMS microphone thinner and is suitable for thin products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com