Grease emulsifying agent for coated feed and preparation process thereof

A technology of compound oil and emulsifier, which is applied in application, animal feed, animal feed, etc., can solve the problem of the decline of oil digestion function, and achieve the effect of stable emulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

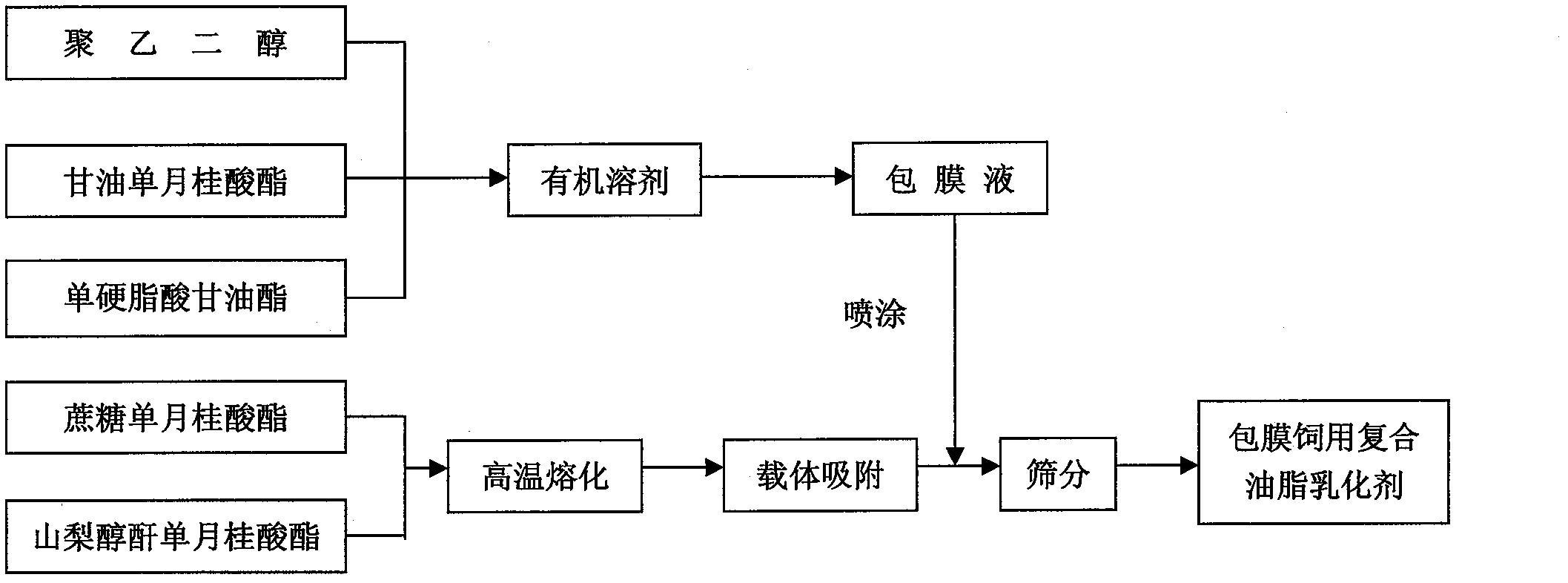

Image

Examples

Embodiment 1

[0013] (1) Weigh each raw material:

[0014] Glyceryl monostearate 100g

[0015] Sucrose monolaurate 150g

[0016] Sorbitan monolaurate 100g

[0017] Glycerol monolaurate 100g

[0018] Polyethylene glycol 250g

[0019] Silica 300g

[0020] (2) The preparation method is: the first step is to heat and melt sucrose monolaurate and sorbitan monolaurate at 100-180°C, then keep it at 60-80°C; in the second step, add silica to adsorb into fine particles Granules; the third step is to dissolve glycerol monostearate, glycerol monolaurate and polyethylene glycol with an organic solvent, and spray the above solution evenly on the fine particles using a bottom jet fluidized bed at a flow rate of 0.1~3L / min , The air inlet temperature is 45~60℃, and the spraying time is 3~4h, which is the finished product. 95% of the finished product passed the 30-mesh analytical sieve.

Embodiment 2

[0022] (1) Weigh each raw material:

[0023] Glyceryl monostearate 100g

[0024] Sucrose monolaurate 150g

[0025] Sorbitan monolaurate 150g

[0026] Glycerol monolaurate 100g

[0027] Polyethylene glycol 200g

[0028] Silica 300g

[0029] (2) The preparation method is: the first step is to heat and melt sucrose monolaurate and sorbitan monolaurate at 100-180°C, then keep it at 60-80°C; in the second step, add silica to adsorb into fine particles Granules; the third step is to dissolve glycerol monostearate, glycerol monolaurate and polyethylene glycol with an organic solvent, and spray the above solution evenly on the fine particles using a bottom jet fluidized bed at a flow rate of 0.1~3L / min , The air inlet temperature is 45~60℃, and the spraying time is 3~4h, which is the finished product. 95% of the finished product passed the 30-mesh analytical sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com