High-efficiency processing system of medium-low viscosity printing ink

A processing system and low-viscosity technology, applied in the field of high-efficiency processing systems, to achieve the effects of shortening sanding time, compact process structure and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

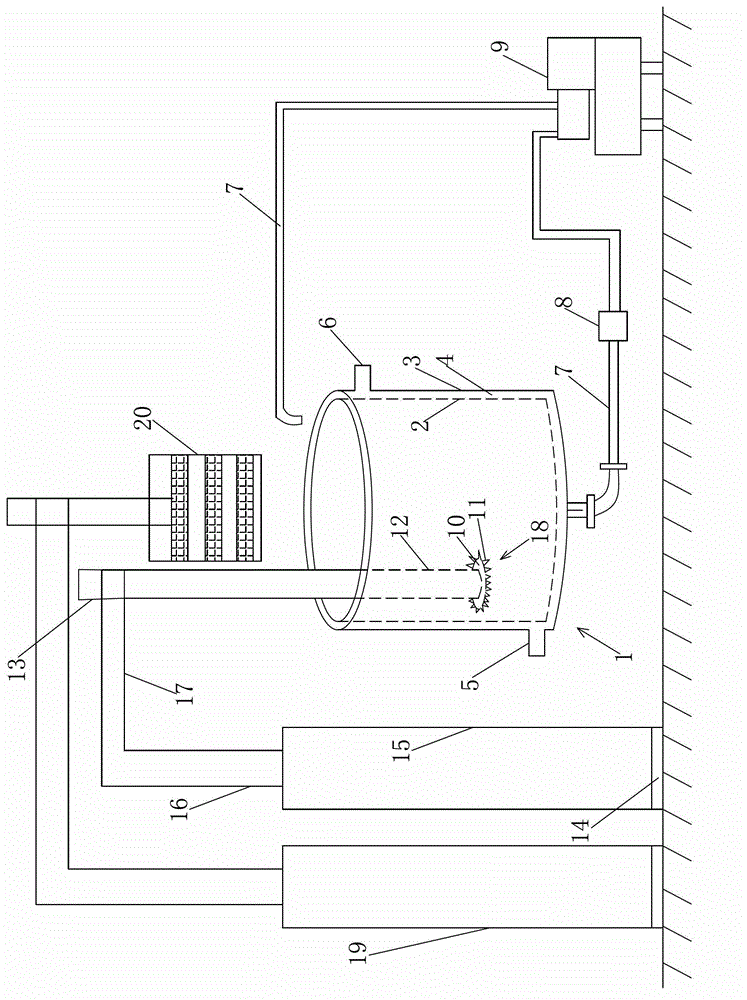

[0017] Embodiment: a kind of high-efficiency processing system of medium and low viscosity printing ink, as figure 1 As shown, the ink ingredients are first added to the reactor 1, and the reactor 1 is a double-layer structure, that is, a hollow interlayer 4 is arranged between the inner layer 2 and the outer layer 3 of the reactor 1, and the reactor 1 The lower end is provided with cooling water inlet 5, and the upper end of reactor 1 is provided with cooling water outlet 6, and described reactor 1 is connected with reactor cooling water circulation device, and described reactor cooling water circulation device comprises water pump, water container (in the figure Not shown), one end of the water inlet pipe is connected to the water outlet of the water container, the other end of the water inlet pipe is connected to the cooling water inlet 5 of the reactor 1 through a water pump, and the cooling water outlet 6 is connected back to the water container through the water outlet pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com