Mounting/dismounting device for disc milling cutter

A loading and unloading device and disk milling cutter technology, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low loading and unloading efficiency, operator injury, heavy weight, etc., to reduce the difficulty of loading and unloading, improve loading and unloading efficiency, and process Create easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

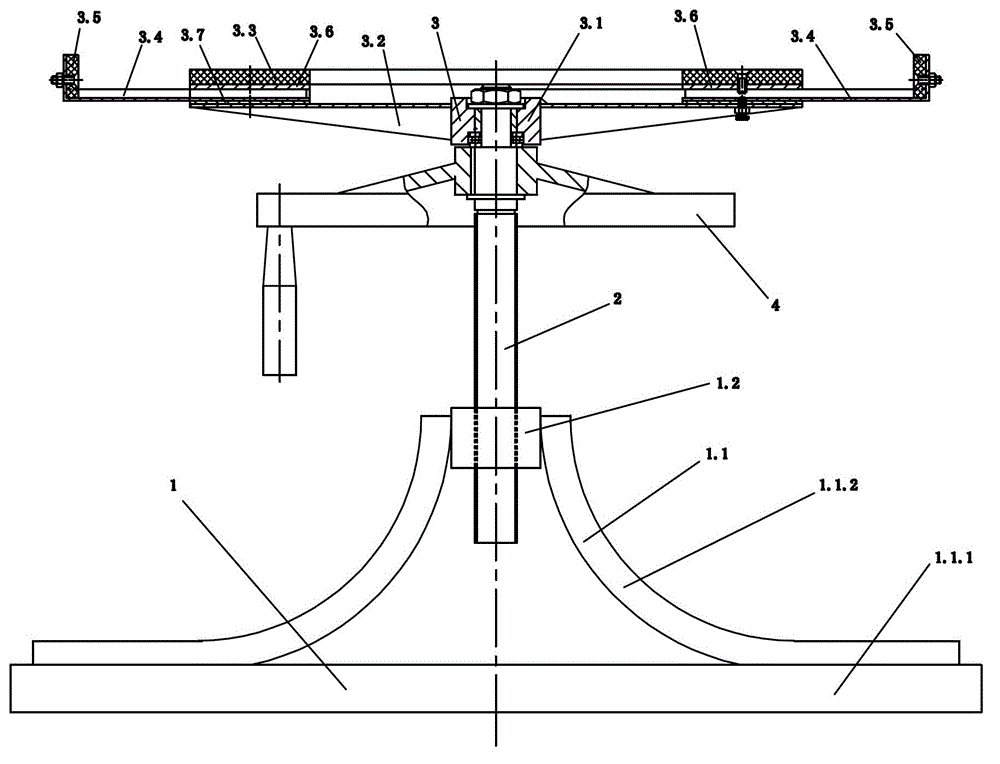

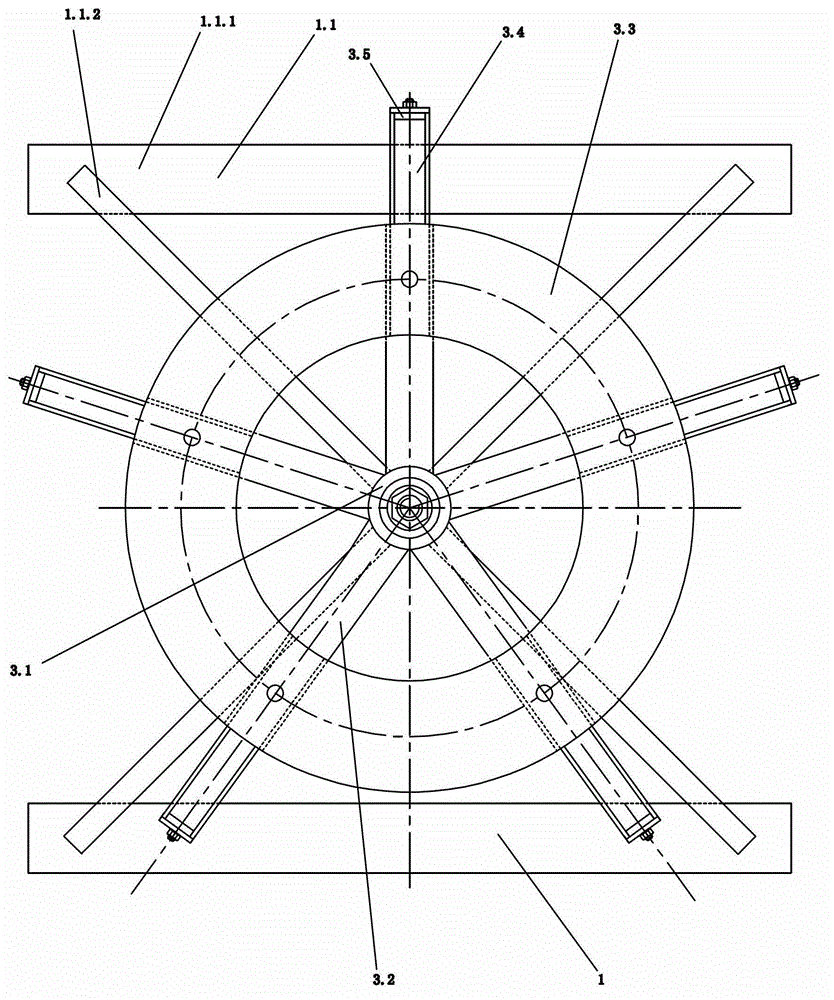

[0020] like figure 1 and figure 2 As shown, the present invention includes a support 1, an elevating shaft 2, a cutter head 3 and a hand wheel 4; 1. A connecting screw block 1.2 with a vertical screw hole is provided on it; the lower end of the lifting shaft 2 is threadedly connected with the connecting screw block 1.2, and the upper end of the lifting shaft 2 is hinged with the cutter head 3; the hand wheel 3 is fixed to the lifting shaft 2 Connected to the bottom of the cutter head 3;

[0021] As a preference, the frame foot 1.1 of this embodiment includes two horizontally opposite feet 1.1.1 and four foot columns 1.1.2, the four foot columns 1.1.2 are symmetrically arranged in pairs, and the four foot columns 1.1.2 The lower ends of each of the four legs 1.1.1 are fixedly connected to one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com