Pressing fit machine for rolling bearing pedestal

A technology of rolling bearings and press-fitting machines, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as long time, hitting on the bearing surface, and difficult assembly, and achieve low production cost, high production efficiency, and concentricity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

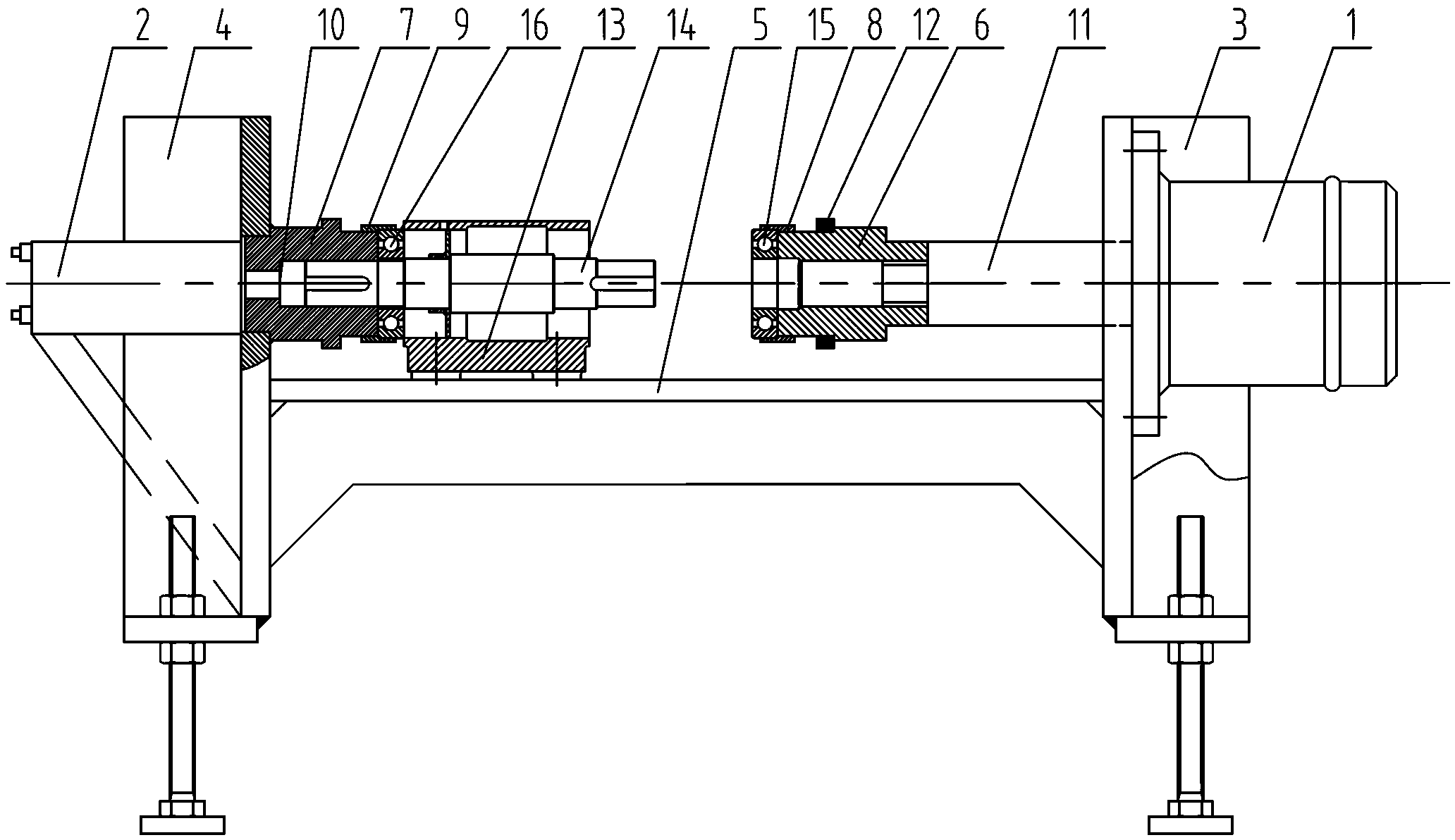

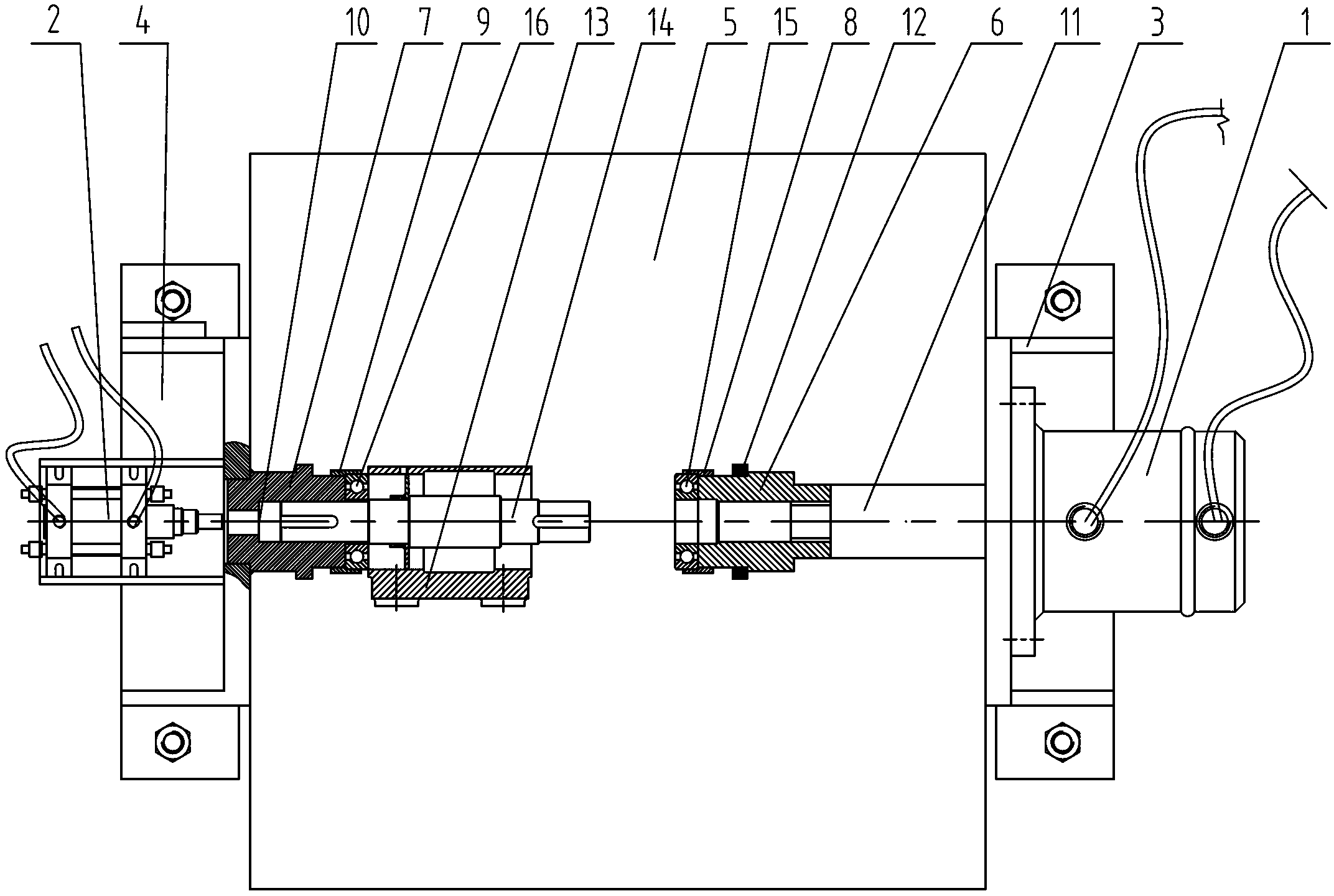

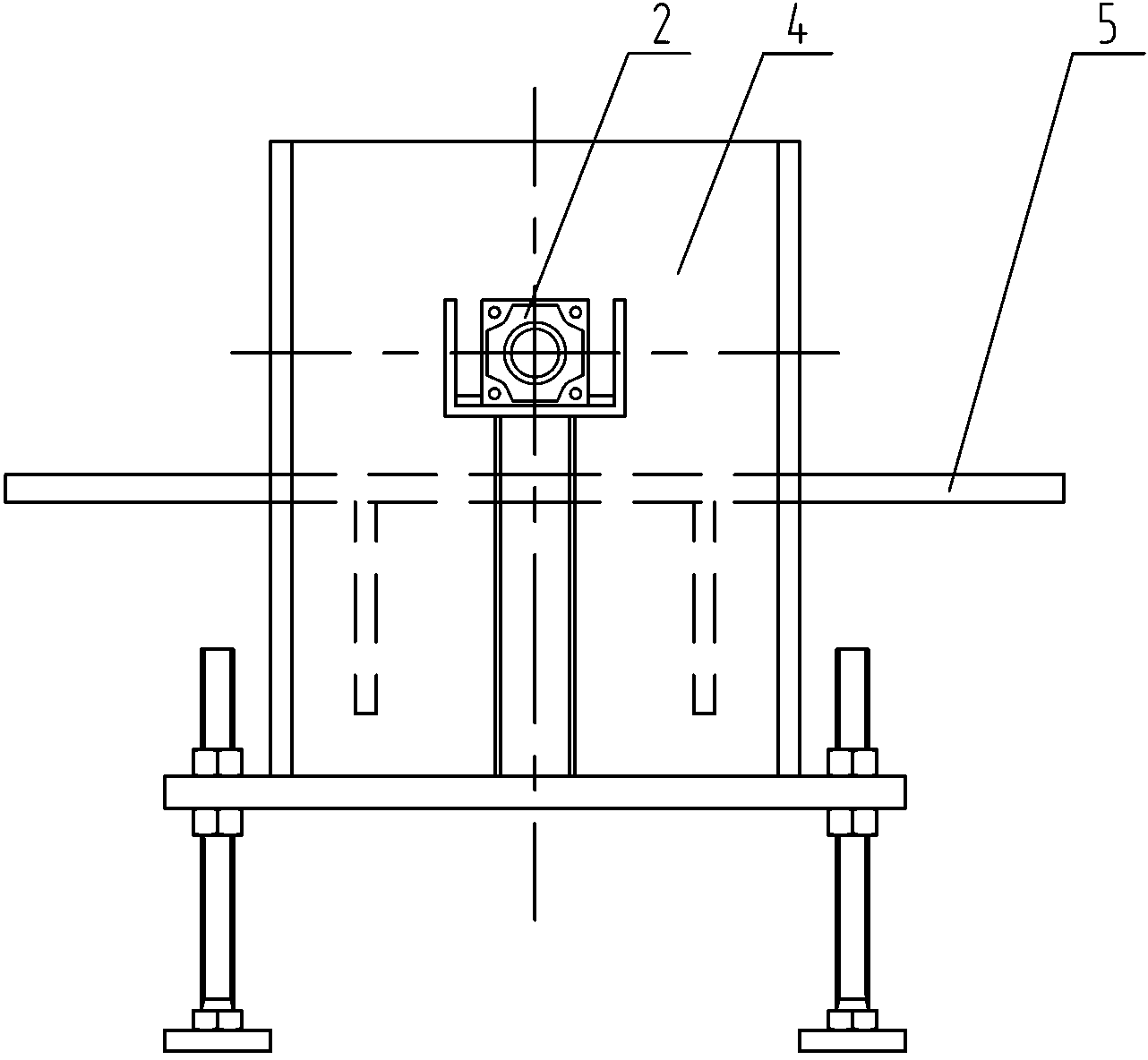

[0021] Such as figure 1 , figure 2 , image 3 and Figure 5 As shown, the rolling bearing mounting and pressing machine mainly includes a hydraulic cylinder 1, a pneumatic cylinder 2, a right support seat 3, a left support seat 4, a press mounting table 5, a main shaft movable guide sleeve 6, a main shaft fixed guide sleeve 7, the first bearing Guide collar 8, second bearing guide collar 9, spindle left moving positioning surface 10, hydraulic cylinder connection plate 11, press-fit ring 12.

[0022] The right support base 3 is fixed with a hydraulic cylinder 1, the piston rod of the hydraulic cylinder 1 stretches out horizontally to the left, the front end of the piston rod is fixed with a piston rod connector 11, and the left end of the piston rod connector 11 is threadedly connected with a main shaft movable guide sleeve 6, The main shaft movable guide sleeve 6 is processed with a stepped inner hole, the right end of the main shaft to be loaded into the bearing can go d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com