Full-automatic box pasting and folding machine

A folding box machine, fully automatic technology, used in container manufacturing machinery, paper/cardboard containers, containers, etc., can solve the problems of slow speed, low work efficiency, overall paralysis, etc., and achieve stable and high work efficiency in conveying cardboard. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

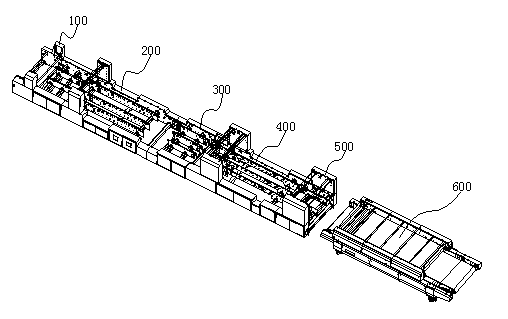

[0027] see figure 1 , a fully automatic box folder folder machine, including a paper output unit 100, an effect unit (not shown), a folding unit 200, a hook bottom 300, a folding unit 400, a crimping unit 500 and a conveying unit 600. The paper output part 100 , the positive part, the turning part 200 , the hook bottom part 300 , the folding part 400 and the crimping part 500 are sequentially connected in pairs by connecting blocks.

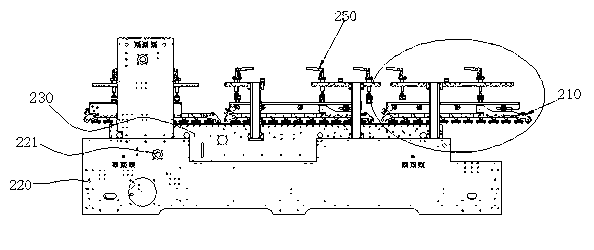

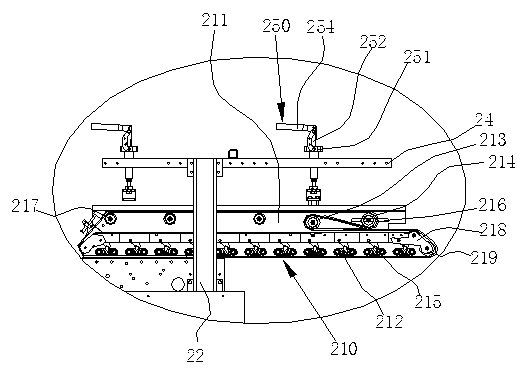

[0028] Please also refer to figure 2 and image 3 , the turning part 200 includes a frame body 220 , an upper guide frame 230 and a plurality of conveying mechanisms 210 , and this embodiment is a three-stage conveying mechanism 210 . The frame body 220 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com