Mount electric vehicle body structure

An electric vehicle, straddle-type technology, applied in motor vehicles, vehicle components, electric power devices, etc., can solve problems such as large width and size, and achieve the effects of reducing vibration, suppressing vibration, and expanding space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

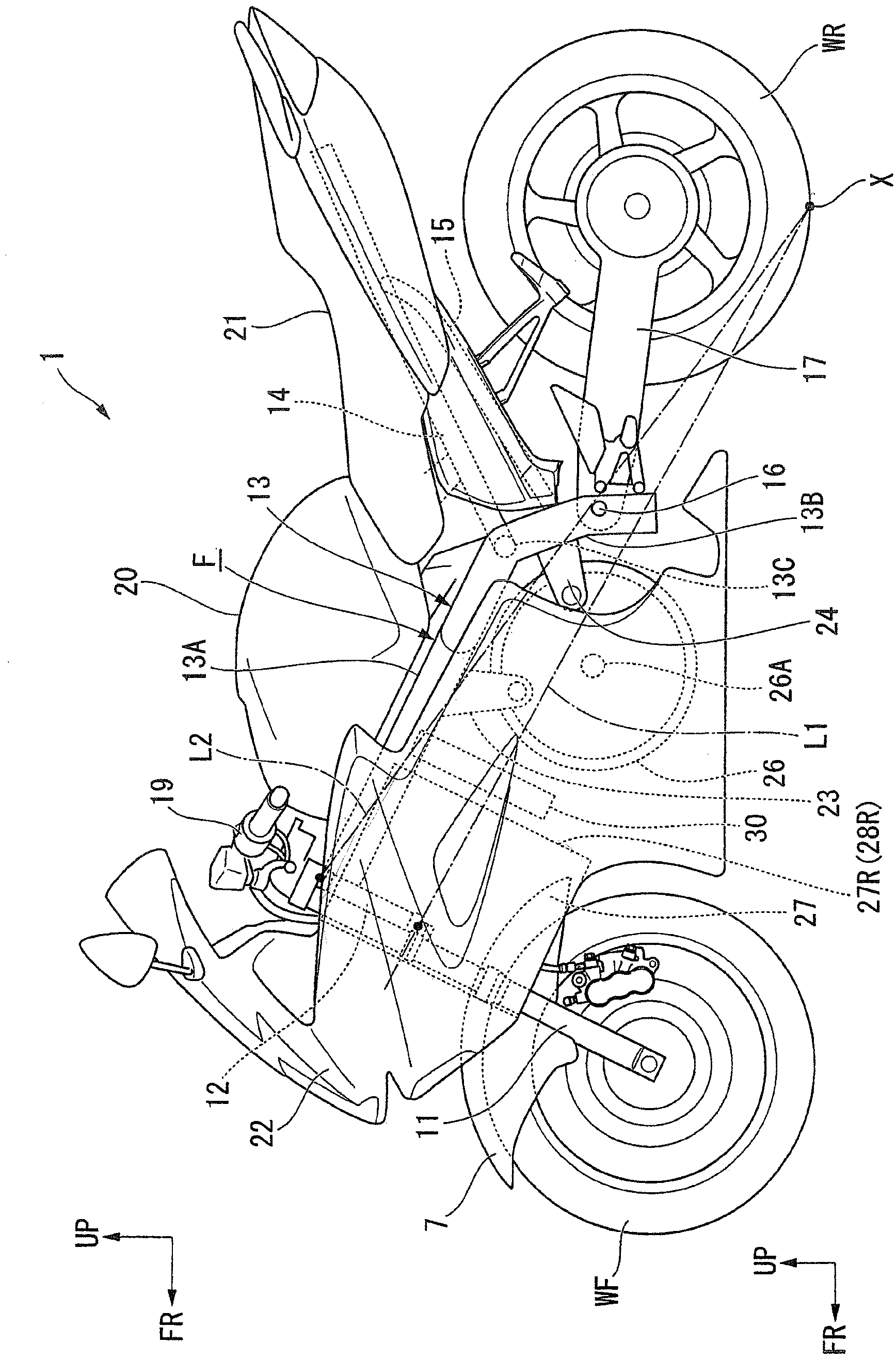

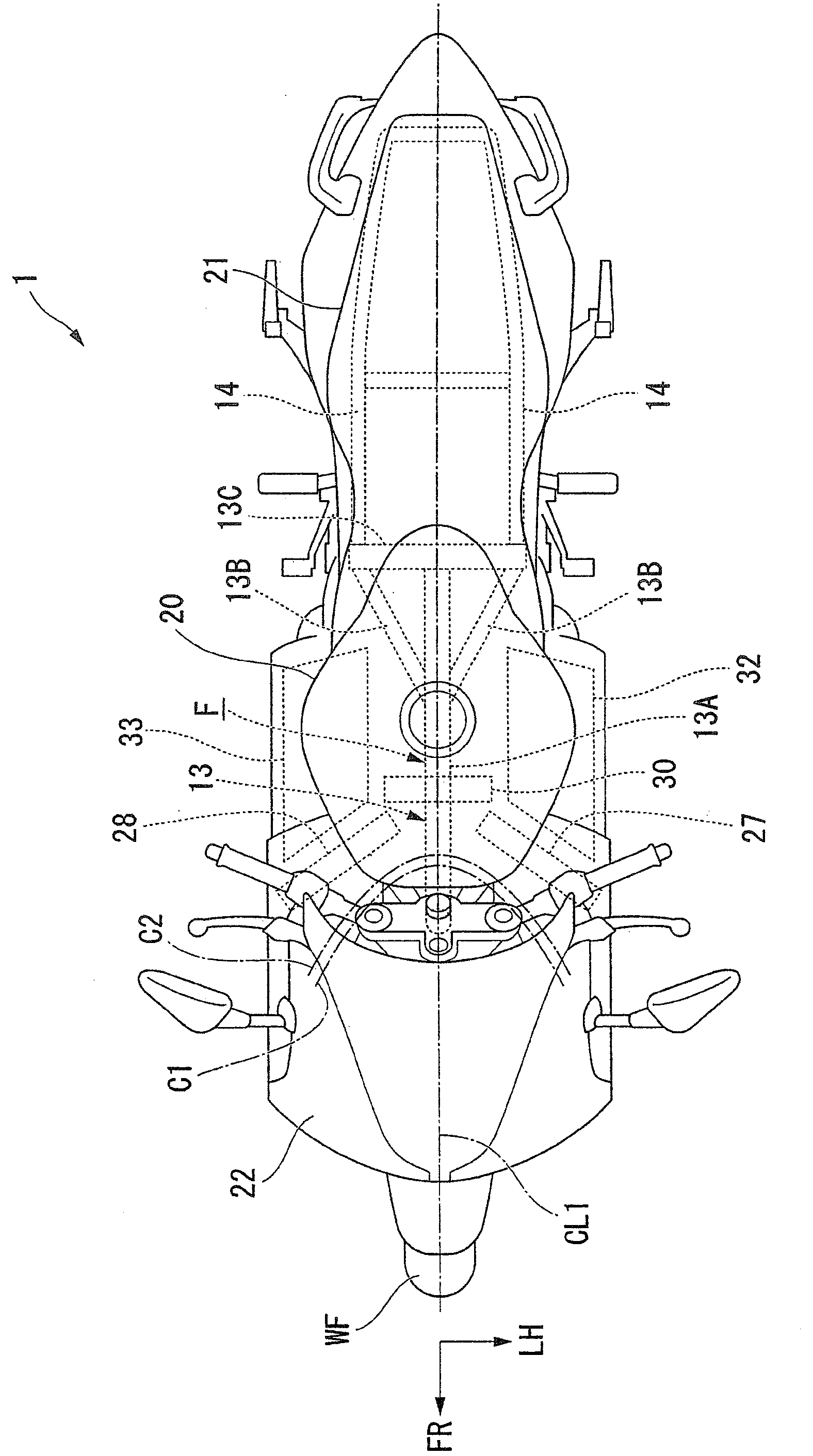

[0052] figure 1 , figure 2 A saddled electric motorcycle 1 to which the configuration according to the first embodiment of the present invention is applied is shown. The frame F of this straddle-type electric motorcycle 1 includes: a head pipe portion 12 that rotatably supports a front fork 11 that pivotally supports the front wheel WF; The main frame part 13 that is bent and extends rearward and downward at a sharp angle; the seat rail part 14 that extends rearward from the vicinity of the above-mentioned curved part of the main frame part 13; The support frame portion 15 is extended and combined with the seat rail portion 14 .

[0053]The head pipe portion 12 has a constant height dimension in the vertical direction, and the main frame portion 13 is coupled to the upper side of the head pipe portion 12 . The main frame portion 13 includes: a front half 13A straightly extending rearward and downward at a gentle angle from the head pipe portion 12; the rear half 13B; the ...

no. 2 approach

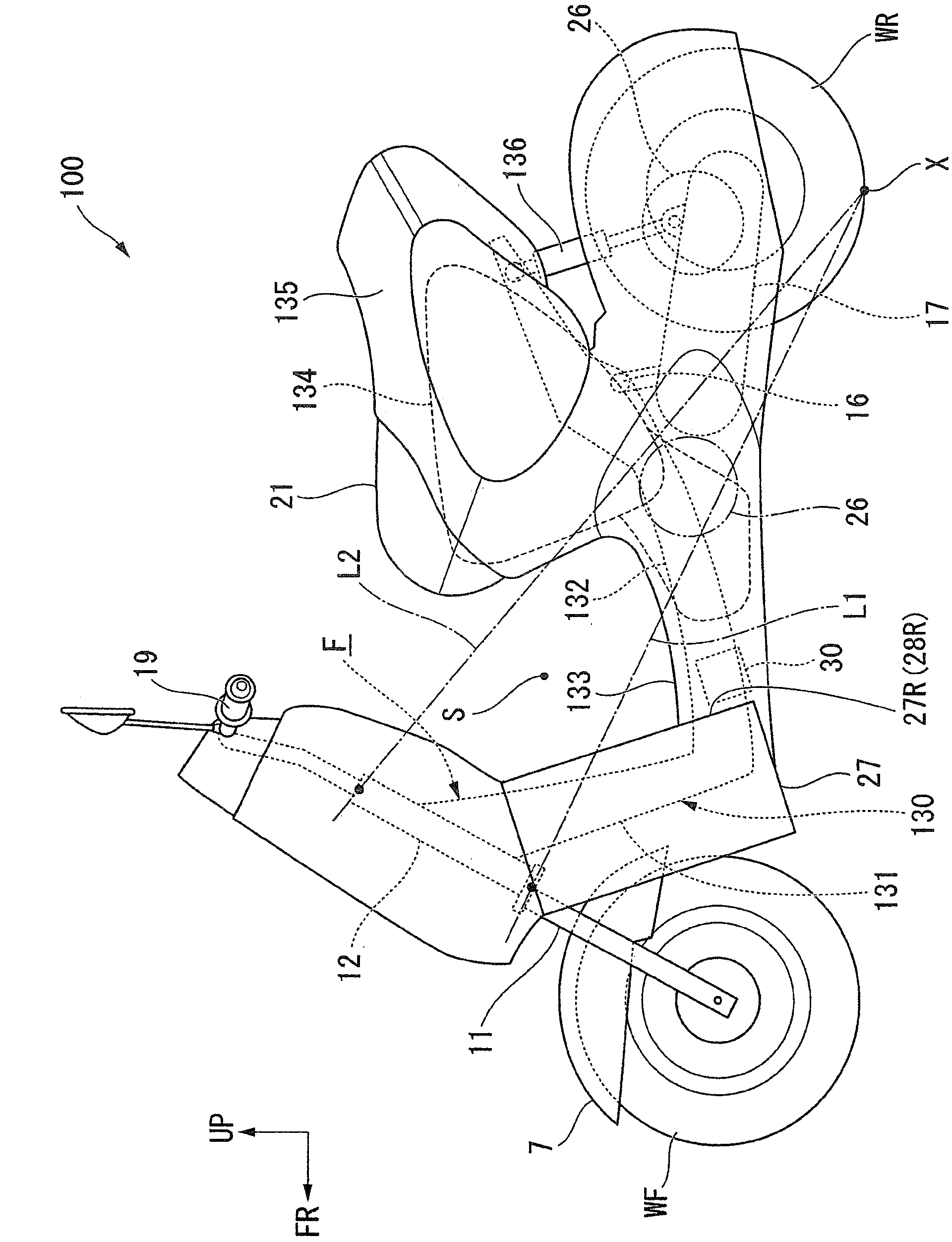

[0077] Next, a second embodiment of the present invention will be described. In this embodiment, in image 3 The structure according to the present invention is applied to the shown low-floor straddle type electric motorcycle 100 . It should be noted that in this embodiment, the same components as those in the first embodiment are denoted by the same symbols, and a part of description is omitted.

[0078] exist image 3 In the straddle-type electric motorcycle 100 shown, the frame F includes: a head pipe portion 12 that rotatably supports a front fork 11 that pivotally supports the front wheel WF; The frame portion 130 bent into an L-shape is observed.

[0079] The frame portion 130 includes a down frame portion 131 extending rearward and downward from the head pipe portion 12 , and a lower frame portion 132 extending rearward and upward at a gentle angle from the lower portion of the down frame portion 131 . A pivot portion 16 formed of a shaft or the like. The arm porti...

no. 3 approach

[0092] Next, a third embodiment of the present invention will be described. In this embodiment, in Figure 5 The configuration according to the present invention is applied to the straddle-type electric motorcycle 200 shown. It should be noted that in this embodiment, the same components as those in the first embodiment are denoted by the same symbols, and a part of description is omitted.

[0093] exist Figure 5 In the saddled electric motorcycle 200 shown, the frame F includes a head pipe section 12 rotatably supporting a front fork 11 pivotally supported on a front wheel WF, and a frame section 230 extending rearward from the head pipe section 12 .

[0094] The frame portion 230 includes a down frame portion 231 extending rearward and downward from the head pipe portion 12 , a lower frame portion 232 extending rearward from a lower portion of the down frame portion 231 in a substantially horizontal state, and a rear end portion of the lower frame portion 232 rearward. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com