Ce:YAG microcrystalline glass used for white light LED and preparation method of Ce:YAG microcrystalline glass

A glass-ceramic and glass technology, applied in the field of solid luminescent materials, can solve the problems of unreasonable design of material components, poor optical properties, etc., and achieve the effects of high transparency, excellent luminescent properties, and unique material components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

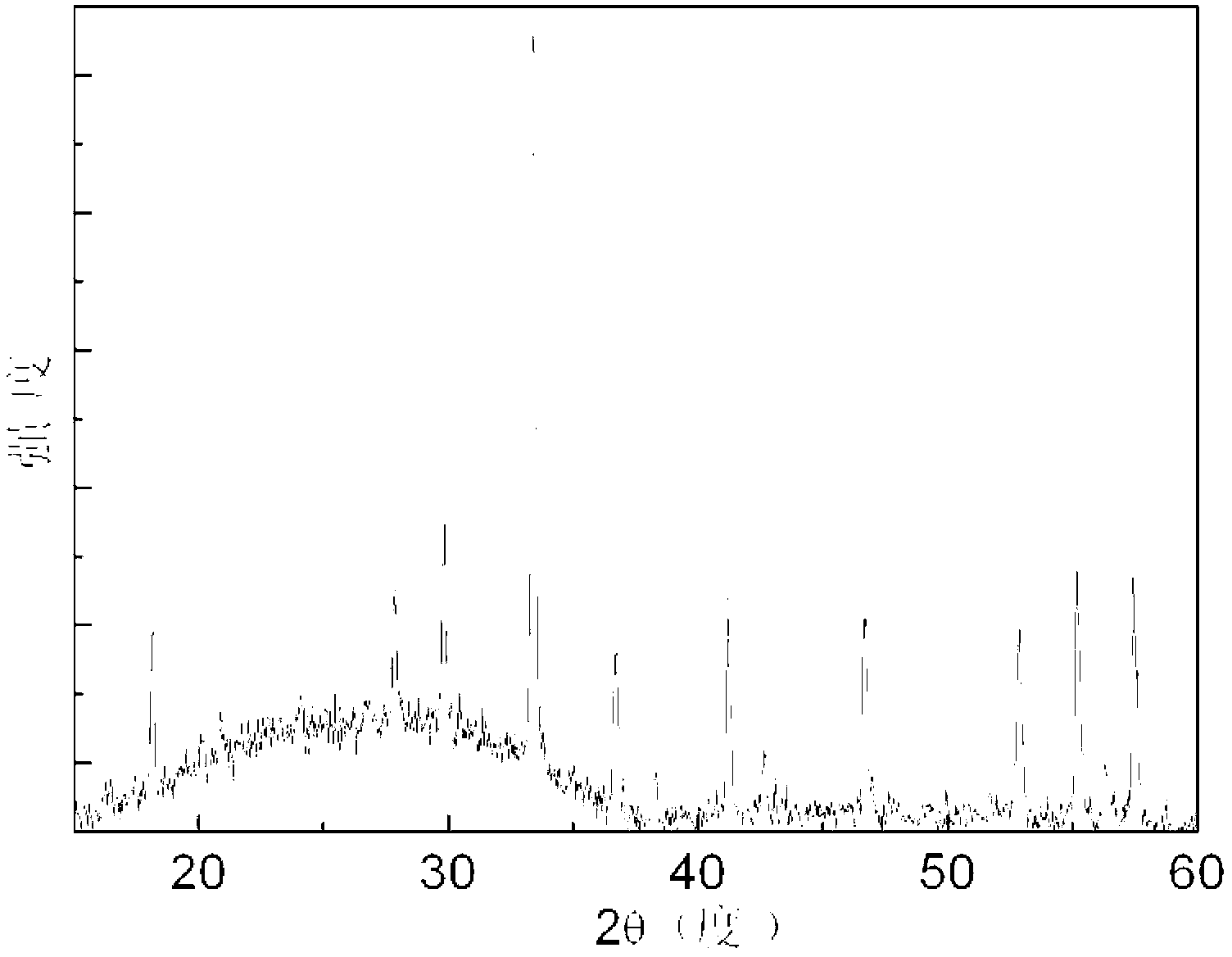

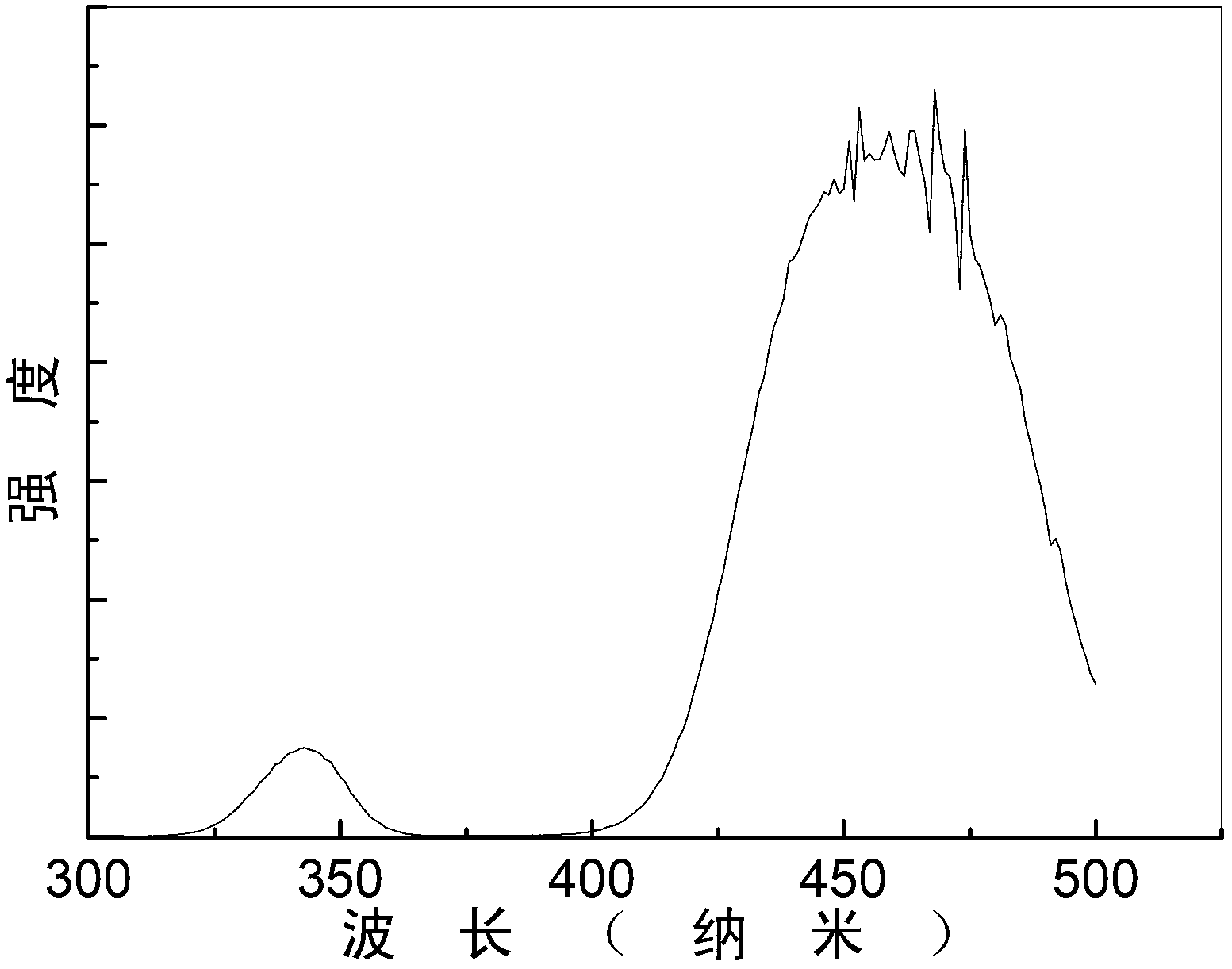

[0097] will analyze pure SiO 2 、GeO 2 , TeO 2 , B 2 o 3 、K 2 CO 3 , ZnO and Sb 2 o 3 Powder, according to 10SiO 2 : 10GeO 2 : 24TeO 2 : 16B 2 o 3 : 15K 2 CO 3 :20ZnO:5Sb 2 o 3 The proportion (molar ratio) is accurately weighed and placed in an agate mortar, mixed and ground evenly in the agate mortar, then placed in a platinum crucible, placed in a resistance furnace, heated to 800°C, and kept for 2 hours to melt , and then, the glass melt is taken out and quickly poured into a mold for forming to obtain a block precursor glass; the obtained precursor glass is smashed into pieces, and after being uniformly ground in an agate mortar, 5wt% of Ce:YAG phosphor powder is added to further After grinding for 2 hours, place it in a crucible, then put it into a resistance furnace, heat it to 700°C, and keep it warm for 1 hour to melt it. Then, take out the glass melt and quickly pour it into a mold to form it to obtain block glass ceramics (such as figure 1 shown); Fin...

Embodiment 2

[0100] will analyze pure SiO 2 、GeO 2 , TeO 2 , B 2 o 3 、K 2 CO 3 , ZnO and Sb 2 o 3 Powder, according to 10SiO 2 : 10GeO 2 : 24TeO 2 : 16B 2 o 3 : 15K 2 CO 3 :20ZnO:5Sb 2 o 3 The ratio is accurately weighed and placed in an agate mortar, mixed and ground evenly in the agate mortar, then placed in a platinum crucible, placed in a resistance furnace, heated to 800°C and kept for 2 hours to melt, then, the The glass melt is taken out and quickly poured into a mold to form a block precursor glass; the obtained precursor glass is crushed, ground evenly in an agate mortar, and then 1wt% of Ce:YAG phosphor powder is added and further ground for 2 hours Put it in a crucible, then put it into a resistance furnace, heat it to 680°C, and keep it warm for 1 hour to melt it. Then, take out the glass melt and quickly pour it into a mold to form it to obtain block glass ceramics (such as Figure 7 shown); Finally, the obtained glass-ceramic was annealed in a resistance furn...

Embodiment 3

[0102] will analyze pure SiO 2 、GeO 2 , TeO 2 , B 2 o 3 、K 2 CO 3 , ZnO and Sb 2 o 3 Powder, according to 10SiO 2 : 10GeO 2 : 24TeO 2 : 16B 2 o 3 : 15K 2 CO 3 :20ZnO:5Sb 2 o 3 The proportion (molar ratio) is accurately weighed and placed in an agate mortar, mixed and ground evenly in the agate mortar, then placed in a platinum crucible, placed in a resistance furnace, heated to 800°C, and kept for 2 hours to melt , and then, the glass melt is taken out and quickly poured into the mold for forming to obtain a block precursor glass; the obtained precursor glass is smashed into pieces, and after being uniformly ground in an agate mortar, 15wt% of Ce:YAG phosphor powder is added to further After grinding for 2 hours, place it in a crucible, then put it into a resistance furnace, heat it to 650°C, and keep it warm for 1 hour to melt it. Then, take out the glass melt and quickly pour it into a mold to form it to obtain block glass ceramics; finally Put the obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com