Ink composition and application for same, as well as product with selectively-metallized surface and preparation method for same

An ink composition and a technology for the composition, applied in the application, ink, metal material coating process and other directions, can solve the problems of increasing process complexity, increasing operating costs, and complicating processing processes, achieving low prices and reducing production costs. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of the ink composition according to the present invention is not particularly limited, as long as the titanium oxide represented by formula I can be uniformly mixed with the binder and optional solvents and additives. For example, the ink composition according to the present invention can be obtained by uniformly mixing the titanium oxide represented by formula I with the binder and optional solvents and additives in a mixer (such as a planetary ball mill). The methods and conditions for uniformly mixing the components in a mixer are well known in the art and will not be repeated here.

[0045] The ink composition according to the present invention can be applied on the surface of an insulating (i.e., non-conductive) substrate, and electroless plating can be performed directly on the surface of the insulating substrate with the ink layer without laser etching. or electroplating to selectively metallize the surface of the insulating substrate, ther...

Embodiment 1

[0086] (1) Titanium dioxide (commercially purchased from Aladdin Reagent Company, with an average particle size of 60nm) is loaded into the middle section of the porcelain boat, the boat is put into the reaction tube and placed in the high temperature section of the muffle furnace, and the reaction tube is placed on both sides Plug the end with a rubber stopper and cool it with dripping water, replace the air in the tube with ammonia gas, and check the sealing condition of the reaction device with pH test paper at the same time, turn on the power after no ammonia gas leaks, and keep the flow rate of ammonia gas at 4cm 3 / s. The muffle furnace was raised to 780°C and held at this temperature for 4 hours, then the boat was cooled to 100°C in an ammonia atmosphere. Turn off the ammonia gas, take out the boat, put it into a desiccator to cool to room temperature, and obtain the titanium oxide shown in formula I. The prepared titanium oxide is subjected to high-speed ball milling to...

Embodiment 2

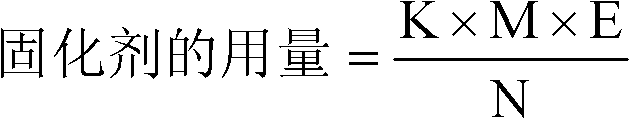

[0092] The same method as in Example 1 is used to prepare the ink composition and selectively metallize the substrate, the difference is that in step (3), after mixing the ink composition prepared in step (2) with the epoxy resin binder , the resulting mixture was applied on the surface of a polyimide substrate by spraying, dried at a temperature of 100° C. for 2 hours, and then cured at a temperature of 120° C. for 1.5 hours. Wherein, in the epoxy resin binder, the epoxy resin is a bisphenol A type epoxy resin, and the epoxy value is 0.58mol / 100g; the curing agent is phthalic anhydride; The ink composition, the consumption of epoxy resin is 10 grams, and the consumption of curing agent is 7.2 grams.

[0093] It was determined that the thickness of the coating was 20 microns, the coating rate was 3.1 μm / h, and the adhesion of the metal layer formed on the surface of the substrate was 4B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap