Implanted and grouted compound pile and construction method

A combined pile and grouting technology, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of limited side friction resistance of the pile body and affect the quality of adjacent piles, etc., to achieve small soil squeezing effect and save machinery The amount of use, the effect of improving the bearing capacity of the foundation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Technical requirements for welding construction, technical requirements for connection between Y-shaped wing plate and pipe pile, technical requirements for stacking and hoisting of pipe piles, technical requirements for drilling soil, technical requirements for grouting body mix ratio design and construction, solidified backfill soil mix ratio design and construction Technical requirements, etc., will not be repeated in this embodiment, but focus on the embodiment of the structure involved in the present invention.

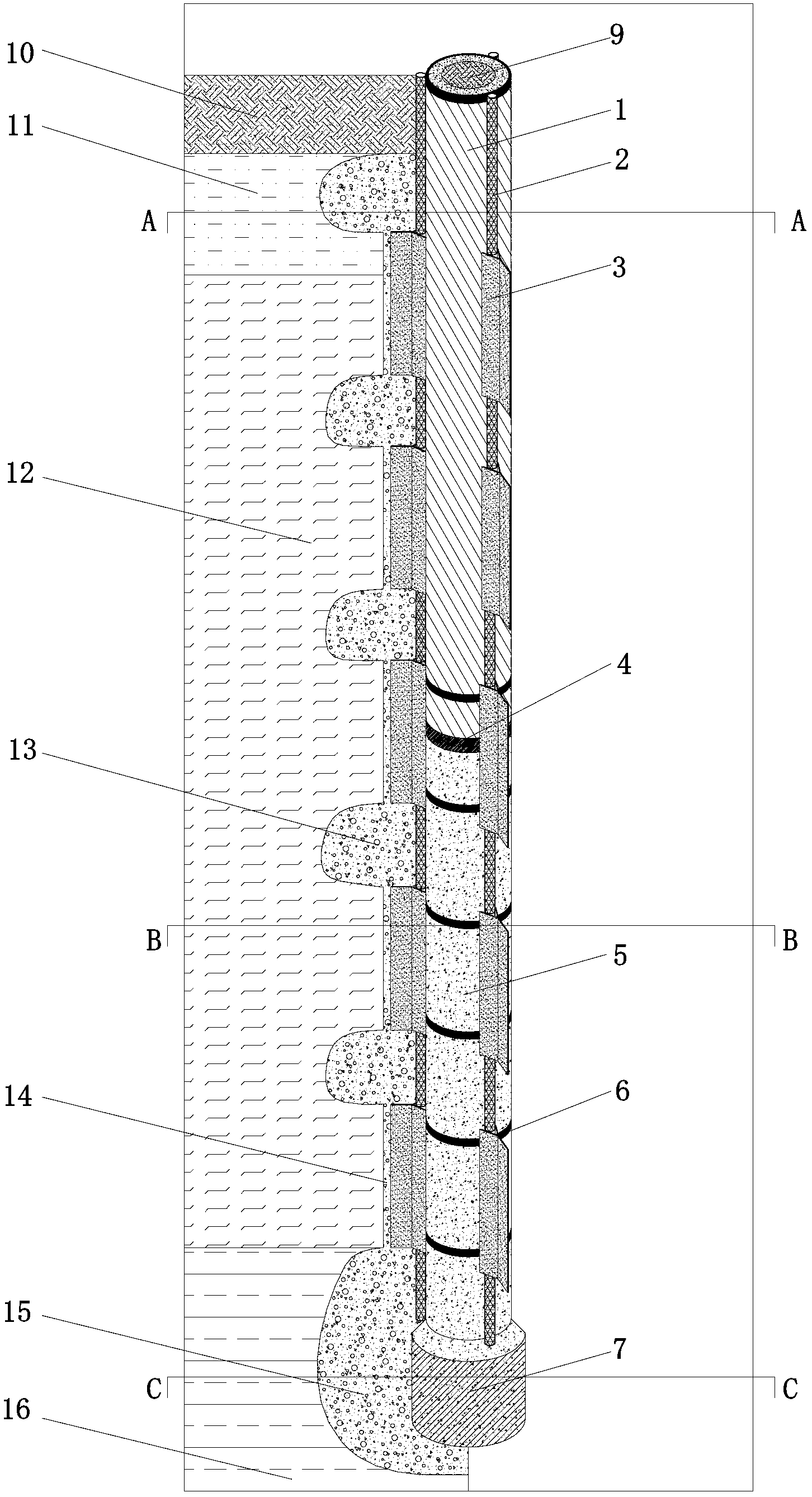

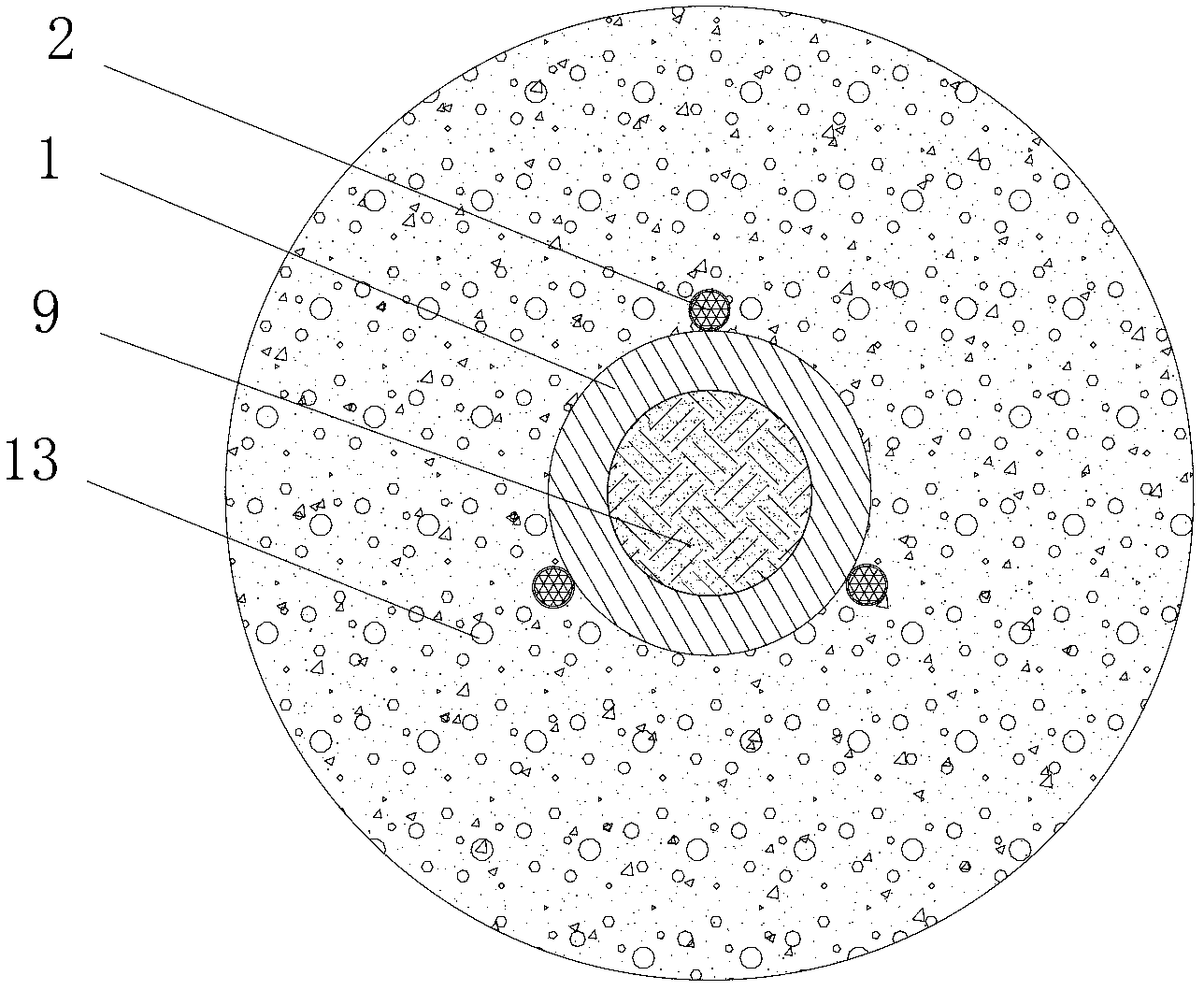

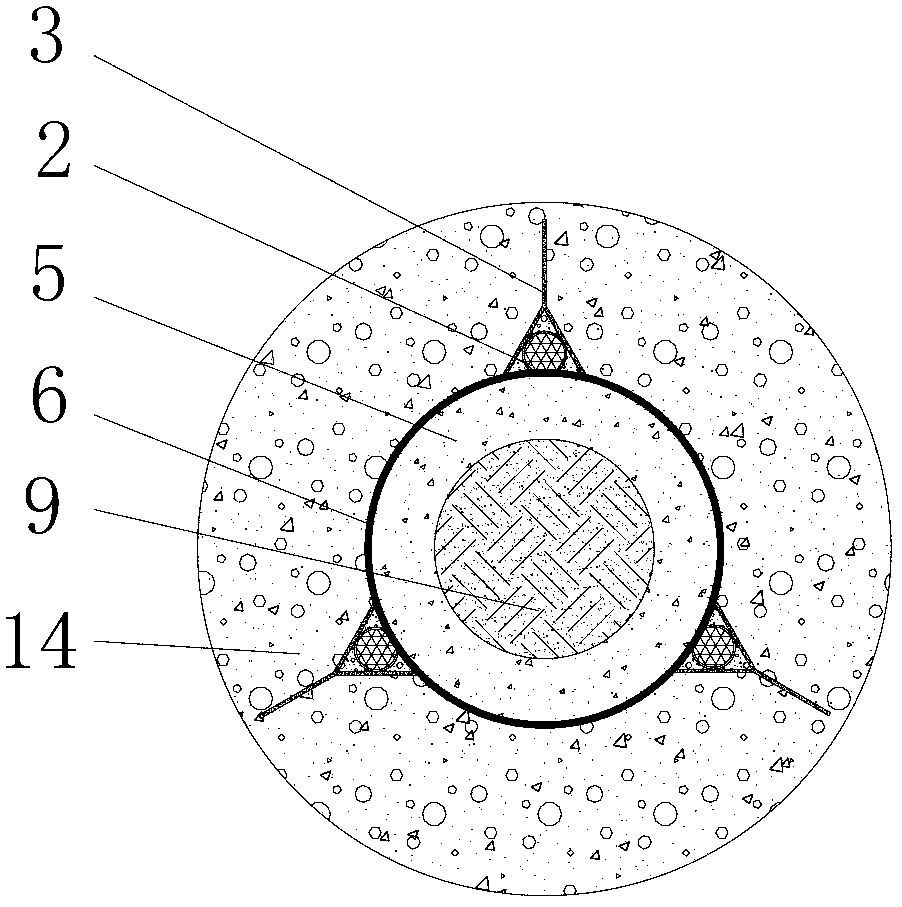

[0042] figure 1 It is a schematic diagram of the structure of the implanted grouting composite pile of the present invention, figure 2 yes figure 1 The sectional view of the Y-shaped wing plate along the A-A line, image 3 yes figure 1 A sectional view of the Y-shaped wing plate and the Y-shaped wing plate fixing ring along the line B-B, Figure 4 yes figure 1 Cut along the line C—C to the sectional view of the prefabricated expanding head, refer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com