Falling-film crystallizer

A technology of falling film crystallization and falling film distributor, which is applied in solution crystallization, chemical instruments and methods, preparation of halogenated hydrocarbons, etc., can solve problems such as ineffective heat exchange, high heat exchange efficiency, and impact on material quality. Achieve the effects of improving heat exchange efficiency, stable material flow, and long material flow distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

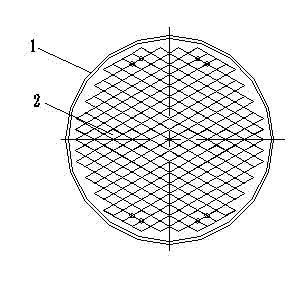

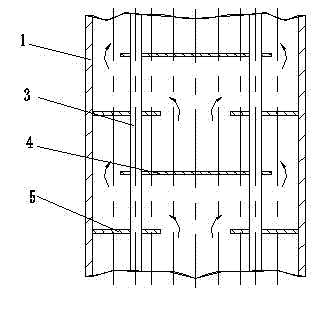

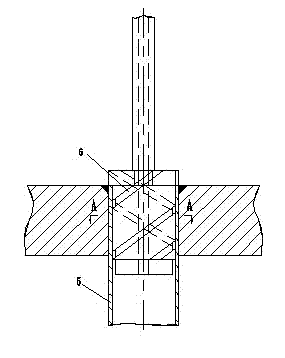

[0015] The present invention includes a falling film distributor and a material heat exchange device arranged in series, wherein the falling film distributor: includes a cylinder body 1 and a material distribution channel formed by several continuous square holes 2 arranged in the cylinder body 1; Heat exchange device: includes a cylinder body 1 and several heat exchange tubes 3 arranged in the cylinder body, and an annular baffle vertically arranged to the heat exchange tubes 3 is arranged in the cylinder body 1 .

[0016] The quadrangular hole 2 is rhombus.

[0017] The arrangement of the annular baffles is as follows: an annular baffle 5 on both sides symmetrically arranged on both sides of the cylinder body 1 with a channel in the middle and a middle annular baffle 4 arranged in the middle of the cylinder body 1 intersect up and down. Set in sequence.

[0018] The middle annular baffle 4 and the two side annular baffles 5 have overlapping parts in horizontal projection. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com