Tea reciprocating sifting machine

A technology of sieving machine and tea, applied in the direction of sieve, solid separation, grille, etc., can solve the problems of hidden safety hazards, high labor intensity, affecting the service life of spring sheets, etc., to improve the sieving effect and the efficiency of shaking the sieve. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

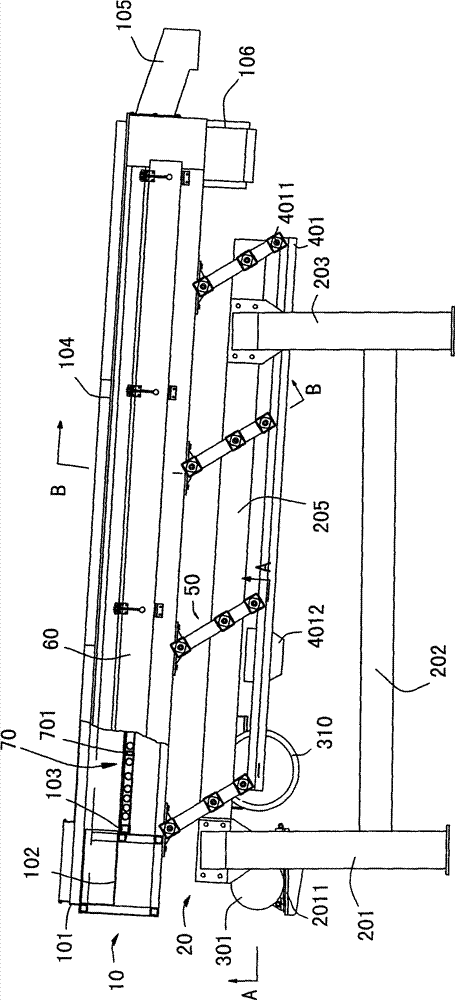

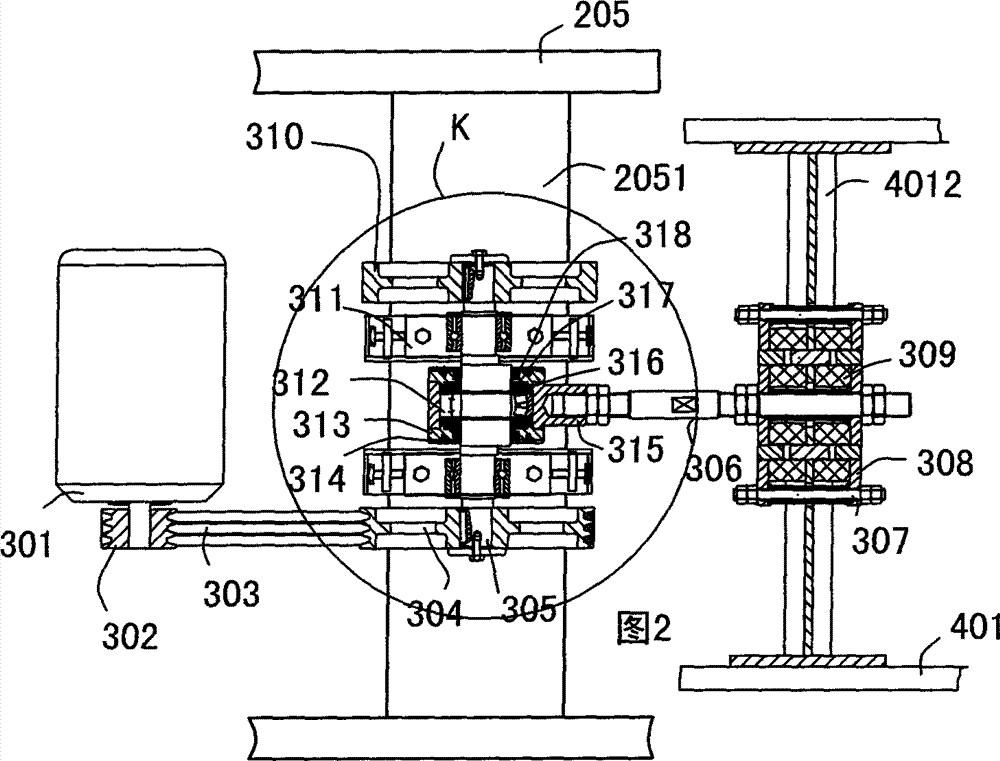

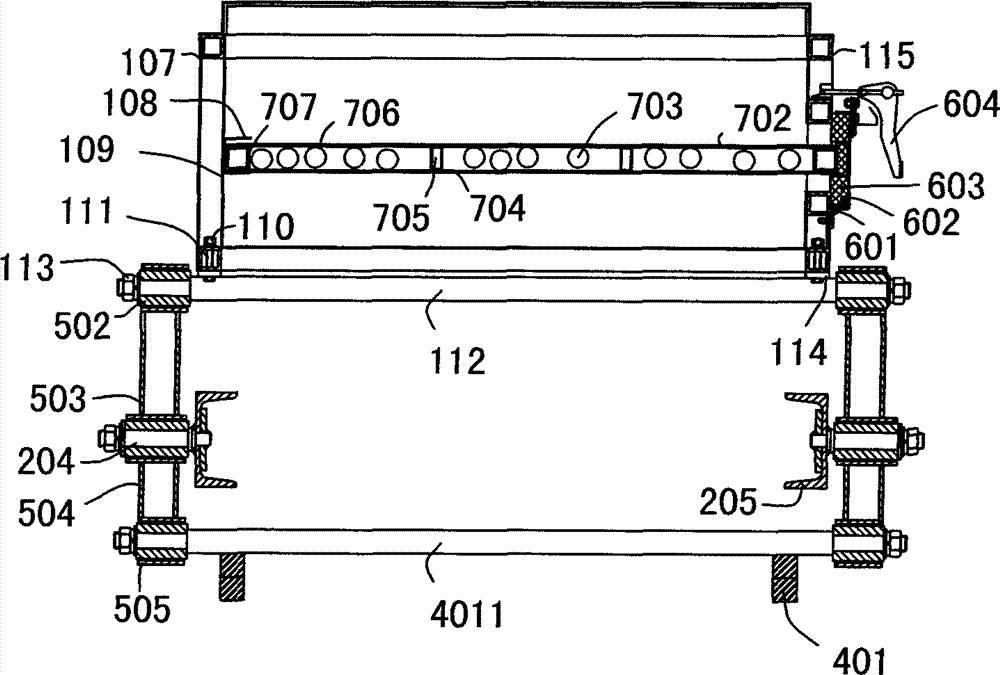

[0016] see figure 1 , and combined with image 3 . The tea shaking sieve machine of the present embodiment is made up of frame 20, sieve bed 10 and transmission mechanism, from figure 1 Observed from the side, frame 20 is formed by two front feet 201, two rear feet 203 through connecting shelves 202 and fixed mount 205, and fixed mount 205 is inclined from left to right, and its horizontal inclination angle is about 3 degrees. The upper and lower ends of four rocking arms 50 (the number can be increased or decreased depending on the length of the sieve bed 10) are respectively hinged on the bottom of the sieve bed 10 and on the drive frame 401, and the middle part is hinged on the outer side wall of the fixed frame 205 through the fixed pin 204 . The transmission mechanism is installed on the bottom wall of the fixing bracket crosspiece 2051 connecting the two fixing brackets 205 .

[0017] The sieve bed 10 is also inclined from left to right, and the inclination matches t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com